Las herramientas de corte de carburo de tungsteno se utilizan ampliamente en industrias como la metalurgia, la carpintería, la industria aeroespacial y la fabricación de moldes. Son fuertes, resistentes al desgaste y pueden cortar materiales duros. Sin embargo, incluso estas herramientas pueden desgastarse o romperse con el tiempo.

Aquí es donde entran en juego los recubrimientos de herramientas. Un buen recubrimiento ayuda a prolongar la vida útil de la herramienta, mejorar el rendimiento y reducir los costos. En este artículo, explicamos cómo funcionan los recubrimientos, qué tipos se utilizan y por qué son importantes para obtener los mejores resultados de sus herramientas de corte de carburo de tungsteno.

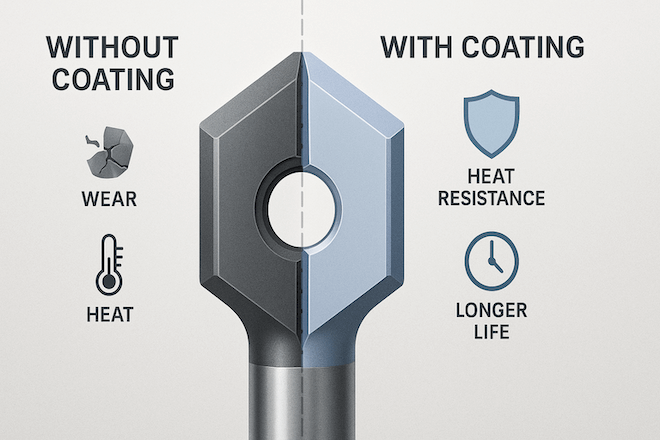

Por qué son importantes los recubrimientos para las herramientas de carburo de tungsteno

Aunque el carburo de tungsteno ya es un material duro, las herramientas de corte fabricadas con él aún enfrentan desafíos:

Fricción y calor al cortar metal.

Desgaste por uso prolongado

Corrosión por refrigerante o productos químicos

Bordes acumulados a partir de materiales pegajosos

Un recubrimiento actúa como un escudo. Protege la superficie de la herramienta y prolonga su vida útil. Además, las herramientas recubiertas cortan con mayor suavidad y mejores resultados.

Obtenga más información sobre cómo funciona el carburo aquí:

👉 Glosario técnico del carburo de tungsteno

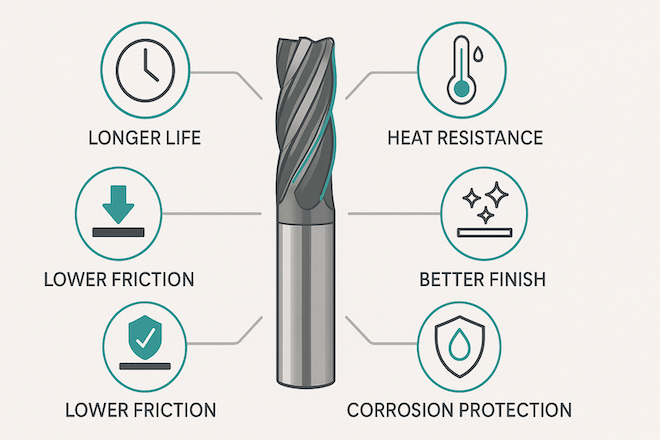

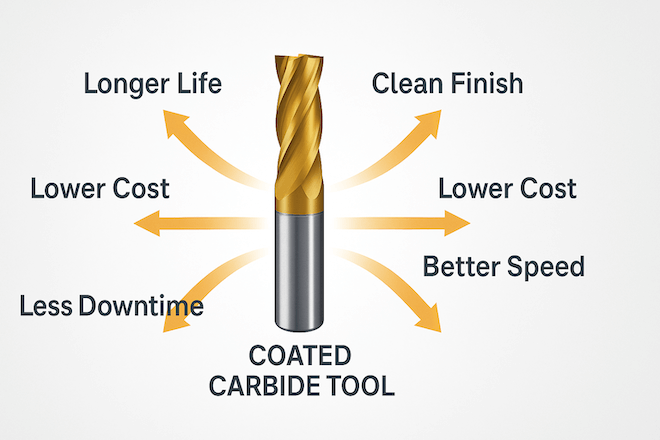

Principales beneficios del uso de herramientas de carburo recubierto

Mayor vida útil de la herramienta

Los recubrimientos reducen el desgaste y hacen que el filo de la herramienta dure más.

Las herramientas se mantienen afiladas para realizar más cortes.

Mejor resistencia al calor

Las herramientas recubiertas pueden soportar velocidades de corte más altas.

Menos posibilidades de sobrecalentamiento o ablandamiento.

Fricción reducida

El corte es más suave, especialmente en metales pegajosos como el aluminio.

Se necesita menos fuerza, lo que ahorra energía.

Acabado superficial mejorado

La parte cortada luce más limpia y suave.

Menos necesidad de pasos de acabado adicionales.

Protección contra la corrosión

El recubrimiento protege contra daños químicos causados por refrigerantes o fluidos.

¿Interesado en herramientas recubiertas?

👉 Herramientas de corte de carburo de Retop

Recubrimientos populares para herramientas de corte de carburo

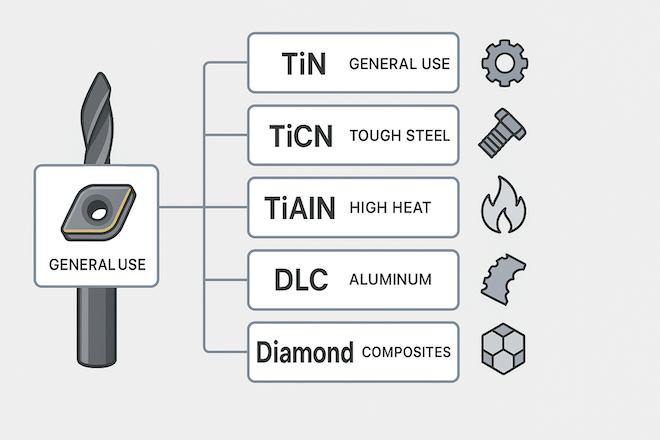

Existen muchos tipos de recubrimientos disponibles. Estos son los más comunes para herramientas de carburo de tungsteno:

1. TiN (nitruro de titanio)

Color dorado

Bueno para uso general

Reduce la fricción y agrega resistencia básica al desgaste.

Popular en carpintería y corte de metales ligeros.

2. TiCN (carbonitruro de titanio)

Color gris azulado

Más duro y resistente que el TiN

Mejor para acero inoxidable y materiales resistentes.

Menor riesgo de astillamiento de los bordes

3. TiAlN / AlTiN (nitruro de titanio y aluminio)

Gris oscuro o negro

Ideal para mecanizado de alta velocidad.

Fuerte resistencia al calor y protección contra la oxidación.

Ideal para corte en seco o uso mínimo de refrigerante.

4. DLC (carbono tipo diamante)

Muy baja fricción

Ideal para aluminio, plástico y materiales no ferrosos.

Evite usar sobre aceros duros.

5. Recubrimiento de diamante CVD

Recubrimiento de diamante auténtico

Excelente para cortar compuestos, fibra de carbono y cerámica.

Muy duro, pero quebradizo; mejor en uso sin impacto.

¿Quieres una guía completa de recubrimiento?

👉 Guía de recubrimiento de carburo de tungsteno

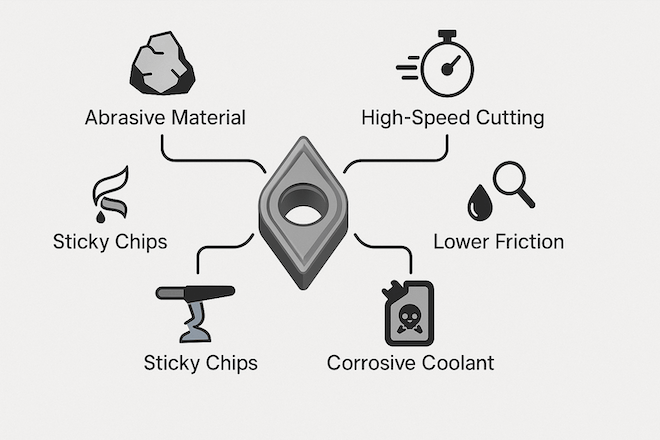

¿Cuándo se deben utilizar herramientas recubiertas?

No todos los trabajos requieren una herramienta recubierta. Pero para un corte de alto rendimiento, los recubrimientos marcan una gran diferencia. Debe usar recubrimientos cuando:

Corte de materiales duros o abrasivos como acero inoxidable, hierro fundido o titanio.

Herramientas en funcionamiento a alta velocidad o mecanizado en seco

Trabajar con refrigerantes o fluidos corrosivos

Corte de materiales pegajosos o blandos que provoquen bordes acumulados

Necesita una herramienta de larga vida útil y un acabado superficial limpio.

Para trabajos especiales, es posible que necesite herramientas de carburo revestidas personalizadas.

👉 Comuníquese con Retop para obtener herramientas de carburo personalizadas

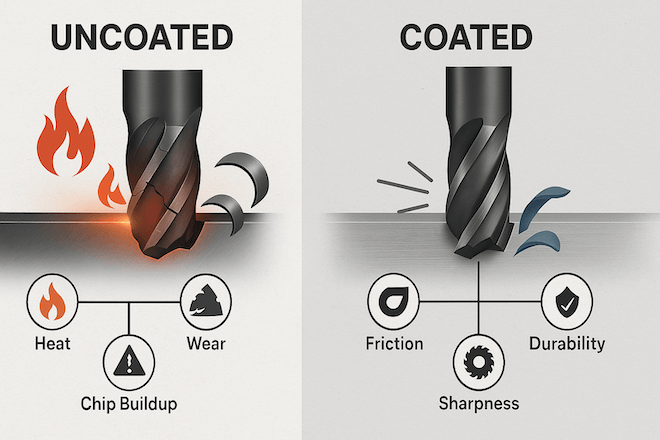

Recubrimiento vs. Sin recubrimiento: ¿cuál es la diferencia?

Comparemos el rendimiento de las herramientas recubiertas y sin recubrimiento:

| Característica | Herramienta sin recubrimiento | Herramienta recubierta |

|---|---|---|

| Vida útil de la herramienta | Más corto | Mucho más tiempo |

| Velocidad de corte | Más bajo | Más alto |

| Resistencia al calor | Moderado | Alto |

| Resistencia al desgaste | Medio | Excelente |

| Calidad del acabado de la superficie | Inconsistente | Suave y limpio |

| Costo-efectividad | Costo inicial más bajo | Menor costo por pieza a lo largo del tiempo |

Los recubrimientos aumentan el precio inicial pero le permiten ahorrar dinero a largo plazo.

El enfoque de Retop para las herramientas de carburo recubiertas

En Retop, comprendemos la importancia de los recubrimientos de alta calidad. Por eso, nuestras herramientas de carburo se someten a un estricto control de calidad y ofrecen múltiples opciones de recubrimiento.

¿Por qué elegir Retop?

✅ Más de 14 años de experiencia en la fabricación de carburo de tungsteno

✅ Herramientas y recubrimientos de carburo personalizados para su aplicación

✅ Exportación a más de 50 países

✅ Calidad certificada ISO 9001

✅ Equipo profesional para I+D y mejoras de recubrimientos

Explora todas las herramientas recubiertas en:

👉 www.retopz.com

Consejos para elegir el revestimiento adecuado

A continuación se ofrecen algunos consejos rápidos que le ayudarán a elegir el recubrimiento adecuado:

Estaño – Buen comienzo para trabajos ligeros o carpintería.

TiCN – Mejor para materiales resistentes y de larga duración.

TiAlN/AlTiN – Ideal para cortes en seco, a alta velocidad y con calor.

Contenido descargable – Excelente para aluminio y plástico.

Diamante CVD – Para fibra de carbono y compuestos

¿No sabes cuál elegir? Pregunta a Retop.

Resumen: Lo que se gana al usar herramientas de carburo recubierto

Mayor vida útil para cada herramienta

Más cortes por ciclo de afilado

Mecanizado más limpio y rápido

Mejor calidad del producto

Costos más bajos a lo largo del tiempo

Menos tiempo de inactividad para cambios de herramientas

Con el recubrimiento adecuado, sus herramientas de corte de carburo de tungsteno funcionarán al máximo.

Reflexiones finales

Los recubrimientos no son solo una característica adicional, sino una inversión inteligente. Le ayudan a ahorrar tiempo y dinero, y a mejorar la calidad de su trabajo. Si aún no utiliza herramientas de carburo de tungsteno recubiertas, ahora es el momento ideal para actualizarlas.

Trabaje con un proveedor confiable como Retop para obtener las herramientas adecuadas, los recubrimientos adecuados y los mejores resultados.