Choosing the right cutting tool material goes beyond just the initial cost. The Total Cost of Ownership (TCO) includes not only the purchase price but also factors like tool lifespan, maintenance, and performance.

Puntas de carburo de tungsteno are known for their durability, but how do they compare to other materials in terms of long-term costs?

In this blog, we’ll examine the TCO of tungsten carbide tips versus other materials to help businesses make informed decisions.

Understanding Total Cost of Ownership (TCO)

The Total Cost of Ownership (TCO) is a comprehensive approach that looks at the full lifecycle cost of a tool or material, from its initial purchase to its replacement. This includes factors such as:

Costo inicial: The upfront price paid for the tool or material.

Maintenance and Repairs: The cost of maintaining and repairing tools over their lifetime.

Operational Efficiency: The impact of tool performance on production efficiency and energy consumption.

Tool Lifespan: How long the tool lasts before it needs to be replaced or reconditioned.

When evaluating tungsten carbide tips versus other materials, the TCO helps companies understand the real cost, not just the purchase price.

Tungsten Carbide Tips: A Durable Investment

Tungsten carbide is one of the hardest materials available, making it an ideal choice for cutting, drilling, and machining tools. The exceptional hardness of carbide tips offers several advantages:

Longer Tool Lifespan: Tungsten carbide tips can withstand high wear and resist corrosion, which extends their useful life compared to softer materials.

High Cutting Efficiency: With superior dureza, tungsten carbide maintains its sharpness longer, leading to more precise cuts and less frequent tool changes.

Tiempo de inactividad reducido: Because carbide tips last longer, there is less downtime for tool replacements and maintenance, improving overall productivity.

While tungsten carbide tips may have a higher initial cost compared to other materials, the extended tool life and improved efficiency often make them a more cost-effective choice in the long run.

Cost of Other Materials in Comparison

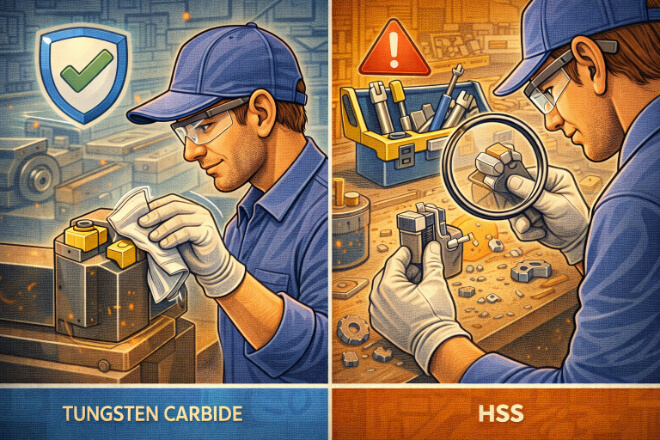

When evaluating the TCO of tungsten carbide tips, it’s useful to compare them with other materials commonly used in cutting tools, such as High-Speed Steel (HSS) and Ceramic tips. Let’s take a look at the advantages and disadvantages of each:

1). High-Speed Steel (HSS) Tips

HSS is a versatile material commonly used in cutting tools. It is less expensive than tungsten carbide but tends to wear out faster, leading to more frequent replacements.

1.1). Pros:

Costo inicial más bajo

Good for general-purpose applications

1.2). Cons:

Shorter tool life compared to tungsten carbide

Higher maintenance and more frequent replacements

Less effective at high temperatures and in abrasive conditions

2). Ceramic Tips

Ceramic cutting tools are known for their dureza y resistencia al desgaste. They perform well in high-temperature applications but are often more brittle than carbide.

2.1). Pros:

Very hard and wear-resistant

Good for high-temperature applications

2.2). Cons:

Brittle and prone to chipping or breaking under impact

Expensive upfront cost

Limited tenacidad compared to carbide

When comparing the TCO of tungsten carbide to HSS and ceramic, tungsten carbide generally offers a better return on investment due to its superior longevity and performance.

Analyzing the Impact of Tool Lifespan

One of the most significant factors in TCO is the tool lifespan. Tungsten carbide tips offer a major advantage here.

While the upfront cost of carbide tips is higher than materials like HSS, their lifespan can be several times longer, reducing the frequency of replacements.

Carburo de tungsteno: With its extreme hardness, carbide tips maintain their cutting edge longer, which means fewer replacements and lower overall tool costs.

HSS: HSS tools typically wear out faster, requiring more frequent sharpening or replacement, which increases the overall cost.

Cerámico: While ceramic tools last longer than HSS, they are more prone to cracking under shock or heavy impact, leading to potential failures and more frequent replacements than carbide.

A longer tool lifespan directly translates to less frequent purchasing and lower maintenance costs, making tungsten carbide a more cost-effective choice for many industries.

Maintenance Costs: A Key Factor in TCO

Another important aspect of TCO is the cost of maintaining and reconditioning tools.

Tungsten carbide tips generally require less maintenance compared to HSS and ceramic tools due to their superior resistencia al desgaste.

Carburo de tungsteno: Requires less frequent maintenance, and when maintenance is needed, it is often in the form of reconditioning rather than full replacement.

HSS: Requires regular sharpening and replacement due to faster wear.

Cerámico: While ceramic tools are wear-resistant, they can suffer from brittleness, requiring careful handling and potentially more frequent replacements if they crack or chip.

Lower maintenance costs mean that tungsten carbide tips often provide a better long-term value, especially in high-volume or high-demand applications.

Performance Efficiency and Productivity

The performance of a cutting tool has a direct impact on production efficiency.

Tungsten carbide tips maintain their sharpness and cutting precision longer, which reduces the number of tool changes required during operations.

Carburo de tungsteno: Consistent cutting performance and high efficiency even after prolonged use. This leads to fewer tool changes, less downtime, and more consistent production.

HSS: As HSS tips wear, cutting efficiency decreases, leading to more frequent tool changes and production slowdowns.

Cerámico: Although ceramic tips offer high performance in specific applications, their brittleness can lead to unexpected tool failures, which disrupt production.

By investing in tungsten carbide tips, businesses can improve overall productivity, reducing downtime and increasing output.

Conclusión

When comparing the Total Cost of Ownership, tungsten carbide tips often provide the best long-term value.

Despite a higher initial cost, their durability, longer lifespan, and lower maintenance needs typically make them the most cost-effective choice over time.

Understanding TCO allows businesses to make smarter, more cost-efficient decisions.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.