When choosing components for pumps, compressors, or turbines, many engineers focus only on the initial purchase price.

But over time, the true cost is not what you pay upfront — it’s what you spend to keep your equipment running efficiently.

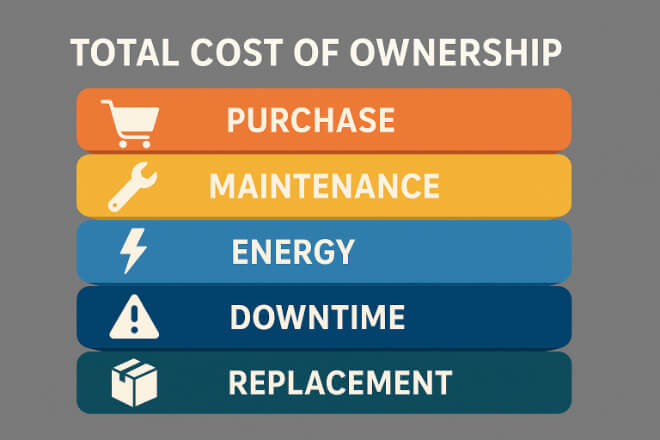

This concept is called Total Cost of Ownership (TCO). It includes not just the purchase cost but also maintenance, downtime, replacement, and energy consumption.

Tungsten carbide bushings, though more expensive initially, offer exceptional value over the long run.

Their durability, resistencia al desgaste, and stable performance reduce operational expenses and extend equipment life.

This article explains why tungsten carbide bushings are a smart long-term investment and how to evaluate their TCO compared with cheaper materials.

Understanding Total Cost of Ownership (TCO)

TCO represents the complete financial picture of using a product during its service life.

It helps decision-makers look beyond the initial quote and consider all cost factors that affect profitability.

Key cost elements include:

Purchase and installation costs

Maintenance and repair costs

Energy efficiency (from reduced friction and wear)

Downtime losses from unplanned stops

Replacement frequency and spare part logistics

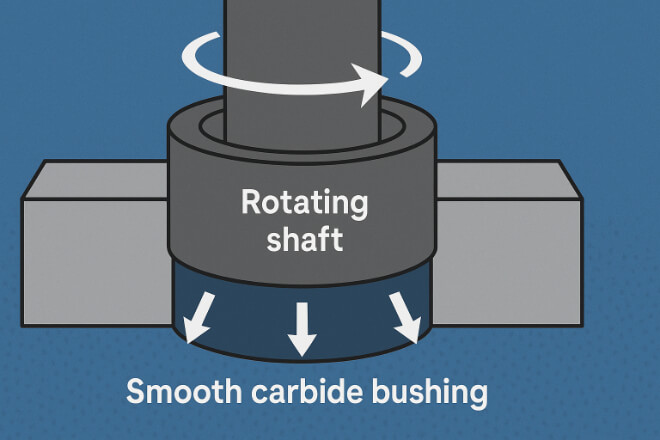

For rotating equipment, bushings play a critical role in preventing shaft wear, maintaining alignment, and reducing friction. The longer they last, the lower your total operating cost.

The High Initial Cost Myth

At first glance, bujes de carburo de tungsteno appear more expensive than steel, bronze, or polymer alternatives. But this view ignores performance differences.

Tungsten carbide bushings can last 5–10 times longer in abrasive, corrosive, or high-pressure conditions.

Over years of operation, this drastically lowers replacement and maintenance costs.

| Material | Average Service Life | Relative Replacement Frequency |

|---|---|---|

| Bronce | 6–12 months | Alto |

| Stainless Steel | 1–2 years | Medio |

| Carburo de tungsteno | 5–10 years | Bajo |

A longer-lasting bushing means fewer shutdowns, lower labor costs, and less lost production time — key benefits for industries where uptime is everything.

Material Properties That Influence Longevity

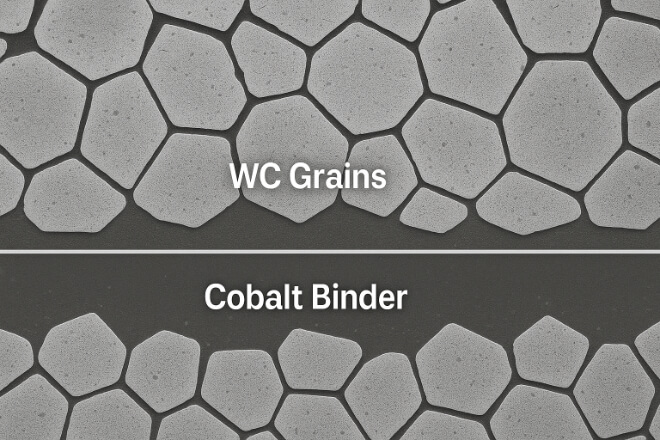

The microstructure of tungsten carbide gives it unmatched resistencia al desgaste and stability.

It’s made of hard WC particles bonded with cobalt or nickel, producing a dense, high-strength material that resists wear, deformation, and corrosion.

Key Performance Advantages:

Dureza: 3× that of hardened steel

Compressive Strength: Over 600,000 psi

Thermal Stability: Performs well beyond 500°C

Chemical Resistance: Stable in acids, alkalis, and seawater

Dimensional Accuracy: Maintains precision under heavy load

These properties ensure consistent performance even in sand-laden water, corrosive chemicals, or high-speed rotation, where other materials would fail quickly.

Maintenance and Downtime Costs

One of the largest hidden costs in plant operations is downtime.

When bushings fail, equipment must be shut down for inspection, part replacement, and realignment — a process that can take hours or even days.

Tungsten carbide bushings reduce this risk because they maintain their surface finish and clearance for years.

Fewer replacements mean:

Less labor cost

Fewer unplanned stops

Higher production output

| Tipo de material | Typical Maintenance Interval | Downtime Risk |

|---|---|---|

| Bronce | Every 6 months | Alto |

| Stainless Steel | Every 12 months | Medio |

| Carburo de tungsteno | Every 3–5 years | Bajo |

En industrias como petróleo y gas, one hour of downtime can cost thousands of dollars. Investing in carbide bushings significantly lowers these risks.

Energy Efficiency and Friction Reduction

Friction directly impacts energy use. Worn or low-grade bushings increase drag on rotating shafts, forcing pumps and compressors to consume more power.

Tungsten carbide bushings maintain smoother surfaces over time, leading to:

Reduced friction losses

Lower operating temperatures

Improved lubrication film stability

Extended bearing and shaft life

A study in pump systems showed that using carbide bushings reduced power consumption by up to 8% over steel components — a measurable energy saving that adds up over years.

Comparing Life-Cycle Costs

To visualize how initial price compares to total lifetime expense, see the table below:

| Material | Costo inicial | Maintenance & Replacement | Total 5-Year Cost |

|---|---|---|---|

| Bronce | $100 | $500 | $600 |

| Stainless Steel | $150 | $300 | $450 |

| Carburo de tungsteno | $250 | $100 | $350 |

Even with a higher upfront price, tungsten carbide bushings offer over 40% savings in total cost of ownership compared with cheaper metals.

Beneficios ambientales y de sostenibilidad

Reusing or refurbishing carbide bushings reduces industrial waste.

Since tungsten carbide is recyclable, many manufacturers offer regrinding and reclaim programs that restore worn parts to like-new condition.

This not only saves money but also supports sustainability goals — reducing carbon footprint and raw material consumption.

Supplier Quality and Consistency

Not all carbide bushings are the same. Differences in powder purity, sintering control, and grinding precision can dramatically impact both lifespan and ROI.

Choose suppliers with:

In-house sintering and finishing

Traceable raw material sources

Proven dimensional control (Ra ≤ 0.05 µm)

Experience in your specific industry (e.g., pumps, turbines, compressors)

Reliable suppliers provide predictable performance — the foundation of long-term cost control.

Conclusión

When viewed through the lens of total cost of ownership, tungsten carbide bushings consistently outperform lower-cost materials.

They reduce replacement frequency, downtime, and energy consumption — leading to lower long-term expenses and higher equipment reliability.

For operations where uptime and efficiency matter most, tungsten carbide bushings are not just components — they are strategic investments that pay off year after year.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.