In the fast-growing electronics industry, precision, speed, and tool durability are essential. As electronic devices become smaller and more complex, manufacturers need tools that can perform with high accuracy on delicate and hard materials. This is where tungsten carbide cutting tools stand out. They help manufacturers machine electronic parts with tight tolerances and long tool life.

In this blog, we explore how tungsten carbide cutting tools are used in the electronics sector, why they are preferred, and how they support production efficiency and product quality.

¿Qué es el carburo de tungsteno?

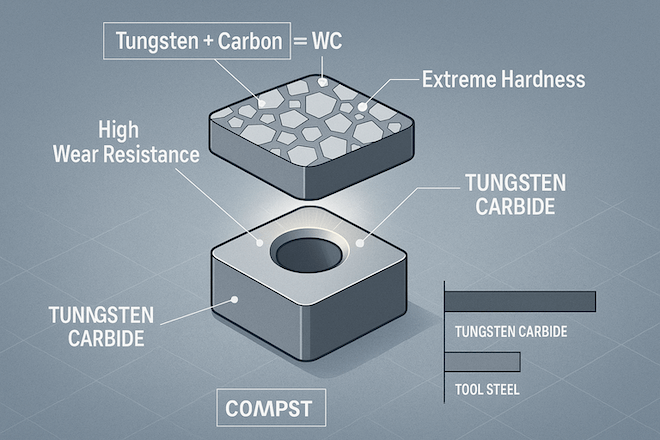

Tungsten carbide is a very hard and wear-resistant material made by combining tungsten and carbon. It is much harder than steel and stays sharp for a long time, even when cutting tough or abrasive materials. Tungsten carbide tools are widely used in industries like electronics, automotive, aerospace, and medical, thanks to their durability, heat resistance, and precision.

Why Tungsten Carbide Tools Are Ideal for Electronics Manufacturing

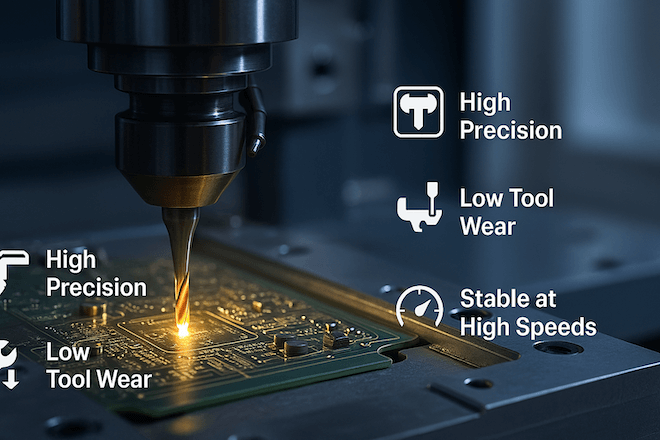

In electronics, components are often very small and made from brittle materials like ceramics, silicon, or PCB substrates. These materials are difficult to machine without causing cracks or defects. Tungsten carbide tools offer several key advantages:

Sharp cutting edges that reduce micro-damage

Low tool wear, even when machining abrasive materials

Dimensional accuracy for parts with tight tolerances

Consistent performance in high-volume production

Because of these benefits, many electronics manufacturers choose tungsten carbide tools for critical processes like PCB drilling, semiconductor packaging, and precision mold making.

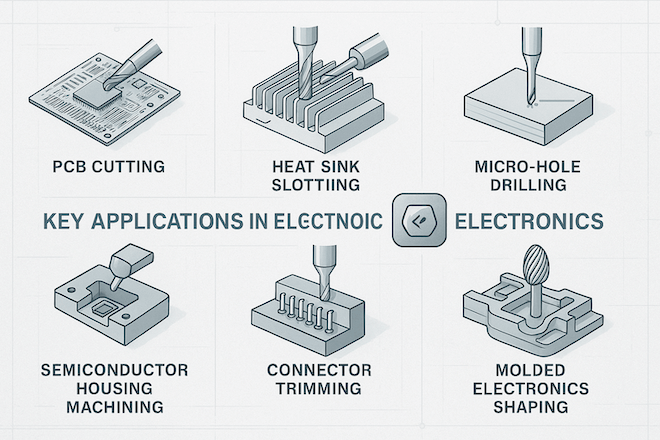

Key Applications in the Electronics Industry

Here are the most common areas where tungsten carbide cutting tools are used in electronics manufacturing:

1. PCB Drilling and Routing

Printed circuit boards (PCBs) need clean, precise holes and edge profiles. Micro-drills and router bits made of tungsten carbide are used to create via holes, slots, and contours with extreme accuracy.

2. Semiconductor Package Machining

Packages for chips often require small grooves or cavities in ceramic or plastic parts. Carbide end mills and micro-cutting tools allow clean, sharp finishes without damaging delicate surfaces.

3. Connector and Contact Production

Metal connectors and contacts need consistent shapes and fine surface finishes. Form tools, punches, and inserts made from tungsten carbide ensure high repeatability and minimal wear.

4. Precision Molding for Microcomponents

Molds used for producing housings or sensor enclosures need to maintain their form over many cycles. Carbide mold inserts and reamers help preserve precision and reduce downtime for mold maintenance.

5. Fiber Optics and Miniature Parts

Fiber optic parts require extreme precision. Carbide tools are used to machine tiny holes and slots with sub-micron accuracy, supporting high-performance data and telecom components.

Benefits of Tungsten Carbide Cutting Tools in Electronics

Here are the core reasons why electronics manufacturers use tungsten carbide cutting tools:

Superior Dureza: Allows cutting of hard and brittle materials like ceramics and fiberglass.

High Precision: Maintains exact dimensions and finishes on small components.

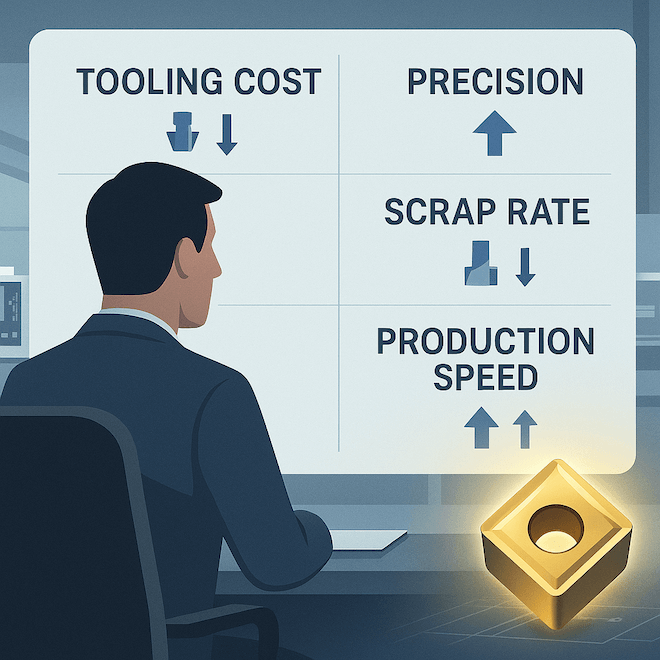

Long Tool Life: Fewer tool changes mean lower production costs and less downtime.

High-Speed Machining: Allows faster cycle times while maintaining quality.

Reduced Waste: Fewer broken tools and scrap parts during fine machining.

Explore more benefits on Retop’s carbide cutting tool solutions.

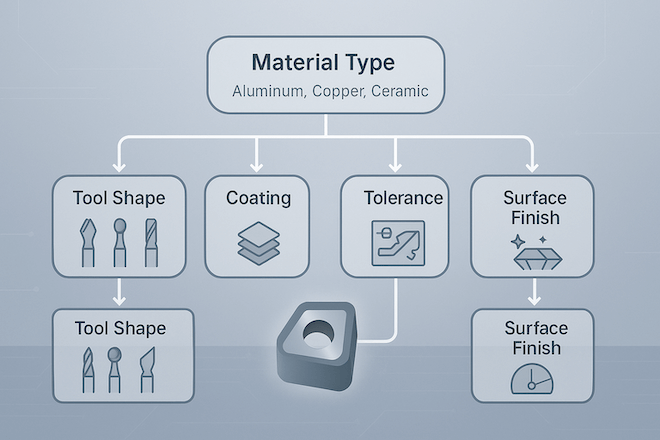

Choosing the Right Carbide Tool for Electronics

When selecting a tungsten carbide cutting tool for electronics, decision-makers should consider the following:

Tool geometry: Sharp angles and micro-edge designs reduce vibration and improve cutting smoothness.

Tamaño del grano: Fine-grain carbide offers higher hardness for ultra-precise cuts.

Revestimiento type: Coatings like TiN or DLC help reduce friction and improve wear life.

Application fit: Select the right tool for drilling, milling, or profiling based on the material and dimensions.

Partnering with a trusted supplier like Retop ensures access to high-quality custom carbide solutions tailored to electronic machining.

Conclusion: Why Decision-Makers Prefer Tungsten Carbide

Para electronics industry leaders, choosing the right cutting tools can make a big difference in product quality, process efficiency, and cost control. Tungsten carbide cutting tools offer the precision, strength, and reliability needed to keep up with today’s fast-paced electronics market.

From PCB fabrication to semiconductor tooling, tungsten carbide is helping manufacturers reduce downtime, boost productivity, and meet strict quality standards.

If you’re in the electronics sector and want tools you can count on, consider working with Retocar — a trusted provider of tungsten carbide cutting solutions for over 14 years.