Por qué es importante el rendimiento de las herramientas de corte en las industrias de la madera y el papel

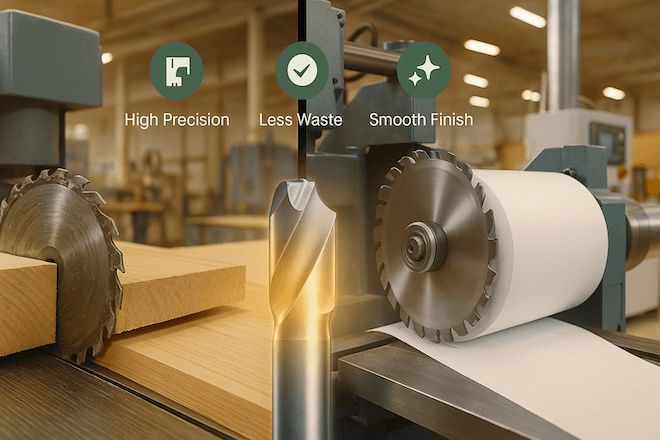

Tanto en la industria de la carpintería como en la del corte de papel, la demanda de velocidad, precisión y mínimo desperdicio es mayor que nunca. Las herramientas de corte se utilizan a diario para dar forma a la madera, recortar láminas, cortar rollos de papel y crear acabados impecables. Si las herramientas no están afiladas ni son duraderas, los resultados pueden ser cortes de mala calidad, un alto desperdicio de material y tiempos de inactividad de la máquina.

Herramientas de corte de carburo de tungsteno Ayudan a resolver estos problemas. En comparación con las herramientas de acero convencionales, las herramientas de carburo se mantienen afiladas durante más tiempo, resisten el desgaste y ofrecen un buen rendimiento incluso con materiales blandos o abrasivos como MDF o tableros laminados.

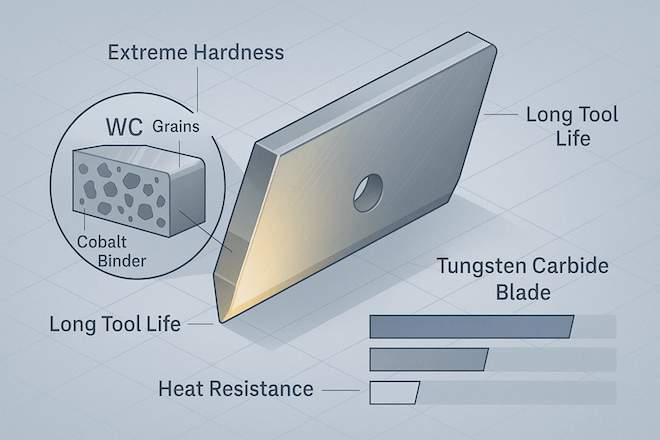

¿Qué es el carburo de tungsteno?

El carburo de tungsteno es un material que se obtiene combinando tungsteno (un metal muy duro) con carbono. El resultado es un material extremadamente duro y resistente al desgaste, mucho más resistente que el acero. Es ideal para herramientas de corte, ya que mantiene su filo durante mucho tiempo, incluso después de muchas horas de uso.

En la carpintería y el corte de papel, esta durabilidad es esencial. Hojas de carburo de tungsteno Puede cortar maderas más duras y productos de papel en capas con facilidad y, al mismo tiempo, dura mucho más que las herramientas tradicionales.

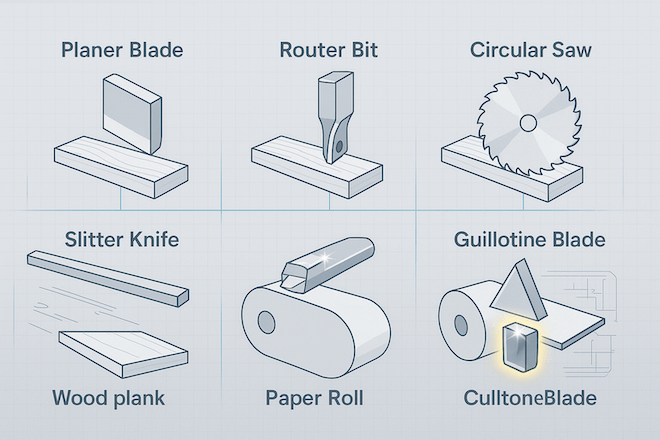

Aplicaciones comunes en las industrias de la madera y el papel

Las herramientas de carburo de tungsteno se utilizan de muchas maneras en la carpintería y el corte de papel:

Carpintería:

Cuchillas cepilladoras para superficies lisas

Brocas de fresado para dar forma a los bordes

Hojas de sierra Para cortar maderas duras y MDF

Insertos de tornero para dar forma al torno

Corte de papel:

Cuchillas cortadoras para cortar rollos de papel a alta velocidad

Cuchillas de tijera para cortes de precisión

Cuchillas de guillotina para corte de pilas

Estas herramientas deben funcionar bajo uso continuo, altas velocidades y tolerancias estrictas.

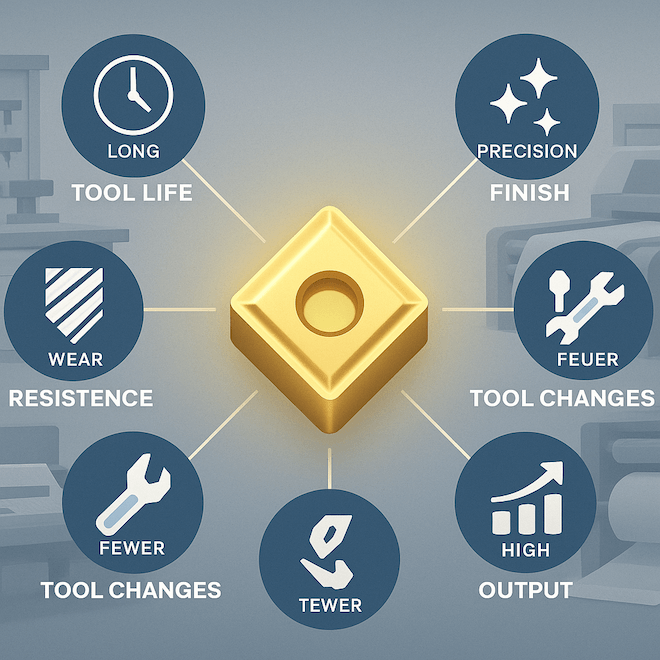

Beneficios de utilizar herramientas de corte de carburo de tungsteno

El uso de herramientas de corte de carburo de tungsteno ofrece varios beneficios clave para estas industrias:

Una mayor vida útil de la herramienta reduce los cambios de herramientas y el tiempo de inactividad

Una mejor precisión de corte garantiza bordes limpios y profesionales.

Una alta resistencia al desgaste significa un mejor rendimiento con materiales resistentes.

Menor costo operativo porque las herramientas duran más y funcionan mejor

Productividad mejorada debido a la reducción de paradas para afilar o reemplazar herramientas

Estas ventajas ayudan a los fabricantes a alcanzar altos objetivos de producción manteniendo una calidad constante.

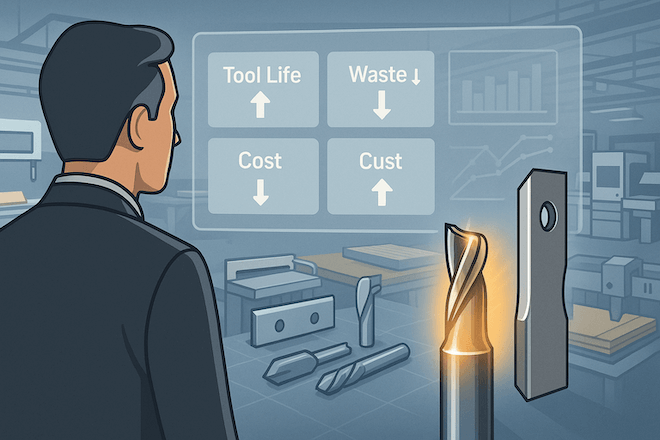

¿Por qué los tomadores de decisiones eligen el carburo de tungsteno?

Para gerentes y tomadores de decisiones, la selección de herramientas afecta directamente el costo, la eficiencia y la satisfacción del cliente. Las herramientas de carburo de tungsteno ayudan a reducir:

Tiempo de mantenimiento de la herramienta

Desperdicio de material por malos cortes

Desgaste del equipo por bajo rendimiento

Paradas no planificadas

Al invertir en herramientas de carburo, las empresas a menudo obtienen retornos rápidos a través de un mejor flujo de producción y menos problemas en el taller.

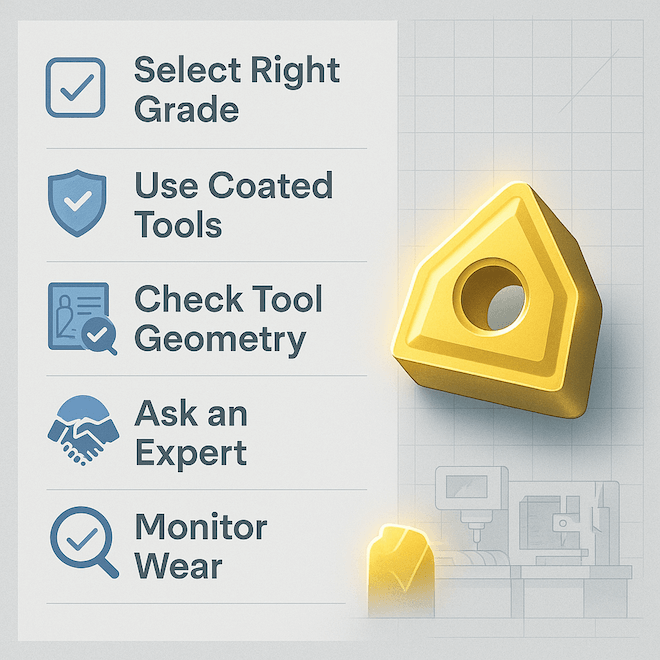

Consejos para elegir la herramienta de carburo adecuada

No todas las herramientas de carburo son iguales. Aquí tienes algunos consejos para obtener los mejores resultados:

Elige la correcta grado de carburo para el material

Usar herramientas recubiertas Para una mejor vida y rendimiento

Adaptar la geometría de la herramienta al proceso de corte

Trabaje con proveedores confiables como Retop para el diseño de herramientas personalizadas

Controle periódicamente el desgaste de la herramienta para mantener la calidad del corte

Conclusión

Carpintería y recorte de papel Exigimos herramientas de alta calidad y larga duración. Las herramientas de corte de carburo de tungsteno ofrecen la durabilidad, precisión y eficiencia que las fábricas modernas requieren. Ya sea para dar forma a muebles de madera fina o cortar rollos de papel grandes, estas herramientas mantienen las máquinas funcionando a la perfección y los productos con un aspecto impecable.

Para lograr el éxito a largo plazo, es fundamental elegir el socio de herramientas adecuado. Obtenga más información sobre soluciones de alta calidad en www.retopz.com.