In the world of modern manufacturing and precision machining, herramientas de corte de carburo de tungsteno are essential.

Ya sea que estés en aeroespacial, automotor, petróleo y gas, or scientific research, these tools offer high performance, long life, and consistent results.

But why is tungsten carbide such a powerful material? And how do these tools serve both industrial and scientific needs?

This article breaks it down in simple terms. We’ll explore what makes tungsten carbide special, how it’s used, and why choosing the right carbide tool matters for your production or research goals.

¿Qué es el carburo de tungsteno?

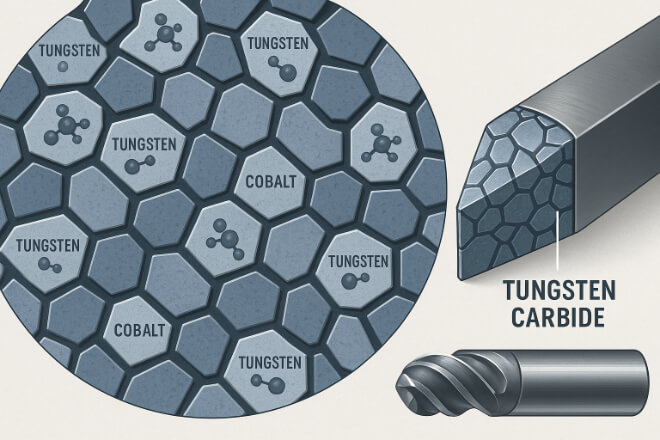

Tungsten carbide is a compound made from tungsten and carbon, often combined with cobalt to create strong, hard cutting materials. It’s one of the hardest known materials after diamond.

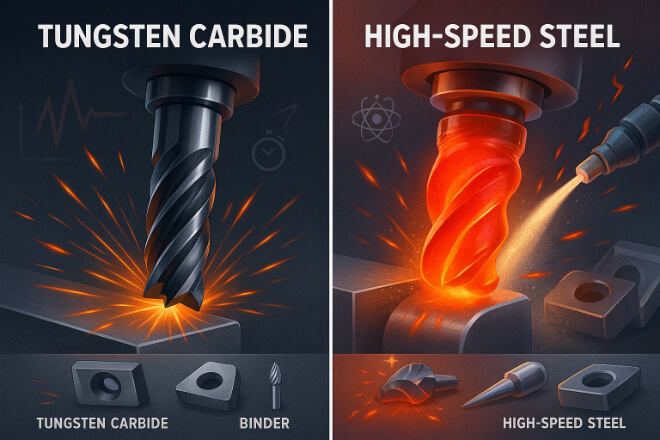

Unlike traditional tool steels, carbide tools can handle high speeds, tough materials, and extreme heat—all without losing shape or dulling quickly.

Why Use Tungsten Carbide in Cutting Tools?

Here’s what makes tungsten carbide cutting tools a go-to solution:

Dureza: Stays sharp longer than high-speed steel.

Heat resistance: Withstands extreme cutting temperatures.

Resistencia al desgaste: Slower tool wear means fewer replacements.

Dimensional stability: Maintains accuracy during heavy-duty operations.

These qualities make carbide ideal for modern machining where precision and speed are key.

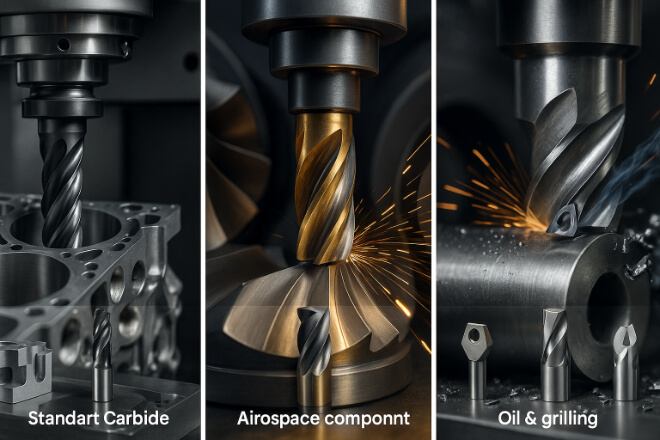

Industrial Applications of Carbide Tools

In industry, time is money. Downtime, poor surface finish, or inaccurate cuts can cost thousands.

Common industrial uses include:

CNC machining for automotive engine parts

Aeroespacial parts production

Drilling and boring for petróleo y gas

Metal fabrication in general manufacturing

Because of their strength, industrial cutting tools made of carbide perform reliably in demanding settings.

Scientific and Research Applications

Carbide tools aren’t just for factories. In scientific labs and research centers, precision is everything.

Las aplicaciones incluyen:

Micro-machining in electronics or medical research

Sample preparation for material analysis

Custom part fabrication for testing equipment

In science, small errors can ruin experiments. That’s why scientific machining uses carbide tools for their extreme accuracy and long-lasting edges.

Types of Tungsten Carbide Tools

Tungsten carbide cutting tools come in many forms. Each serves a different purpose depending on the material and operation.

Here are the most common types:

| Tipo de herramienta | Uso común |

|---|---|

| End Mills | Used in milling for creating slots and contours |

| Inserciones | Replaceable tips used in turning, boring, or milling |

| Drills | Create holes in metal, composites, or plastic |

| Boring Bars | Enlarge or finish holes in precision machining |

| Escariadores | Smooth out holes for high-precision fits |

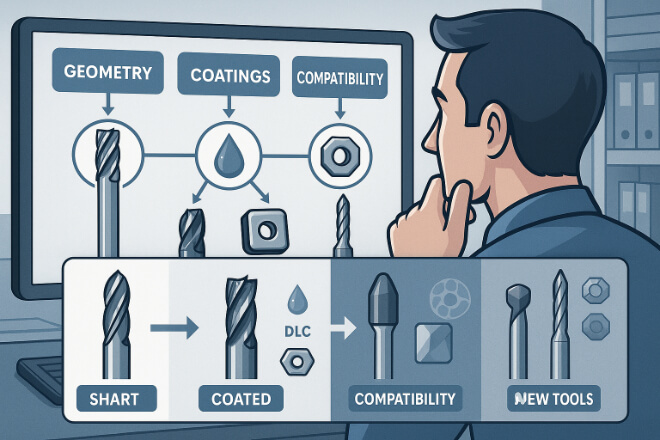

Each tool can be tailored by geometry, coating, or carbide grade depending on the material and cutting speed.

Coatings Make a Big Difference

Many carbide tools are coated to improve performance. The coating helps reduce friction, resist heat, and extend tool life.

Common coatings:

TiN (Titanium Nitride) – Good for general machining

TiAlN (Titanium Aluminum Nitride) – Better heat resistance

DLC (Diamond-Like Carbon) – For non-ferrous metals and plastics

CVD Diamond – Ideal for carbon fiber, graphite, and abrasives

Choosing the right coating boosts efficiency and precision, especially in high-performance tooling environments.

Cost vs. Value of Carbide Tools

Yes, tungsten carbide tools are more expensive than basic high-speed steel. But in most cases, the total cost is lower over time.

Comparemos:

| Factor | HSS Tool | Carbide Tool |

|---|---|---|

| Costo inicial | Bajo | Alto |

| Vida útil de la herramienta | Corto | Long |

| Speed | Lento | Rápido |

| Accuracy | Moderado | Alto |

| Downtime Risk | Alto | Bajo |

In short: with carbide tools, you get fewer tool changes, better part quality, and reduced rework—saving time and money.

How to Choose the Right Carbide Tool

Not all carbide tools are the same. Here’s what to consider:

Material – Different grades are better for steel, aluminum, or composite.

Tool Geometry – Sharp vs. strong edges, number of flutes, helix angles.

Coating Type – Choose based on heat, chip removal, or material stickiness.

Supplier Quality – Low-quality tools wear faster and hurt production.

Tool Maintenance Matters

Even the best tool needs care. Keep your carbide tools in shape with regular inspections and sharpening when needed.

Mejores prácticas:

Clean tools after each use

Use proper holders and avoid tool chatter

Store tools in dry, protected trays

Sharpen before tools get too dull

A little care goes a long way in extending tool life and keeping machining precise.

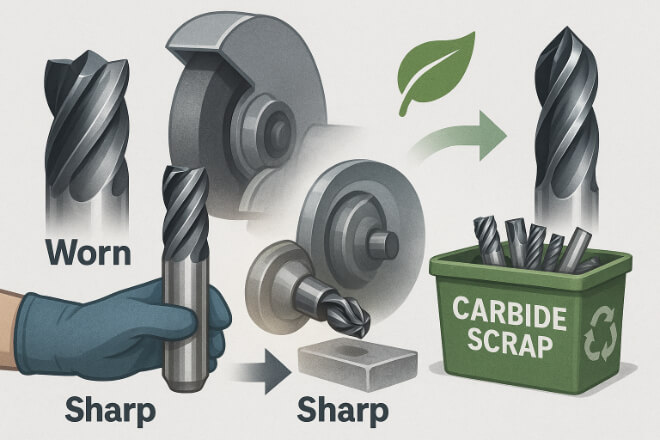

Regrinding and Recycling

Worn-out carbide tools don’t have to be thrown away. They can be reground or recycled, which saves money and supports sustainability.

1). Regrinding:

Restores the cutting edge

Is cheaper than new tools

Maintains original geometry

2). Recycling:

Carbide scrap is valuable

Helps reduce mining of tungsten and cobalt

Many suppliers offer buy-back or credit programs

Always ask your supplier about tool recycling or reconditioning programs.

Scientific Tooling: What Matters Most?

In scientific machining, the requirements are different:

Extreme precision for small parts or samples

Consistent results for research reproducibility

Special geometries for unique materials

Carbide tools make this possible. Labs and research teams should look for micro-grain carbide, nano-coatings, and specialty geometries for best results.

Future Trends in Carbide Tooling

The cutting tool industry is always evolving. Here’s what’s coming:

Nano-structured coatings for longer wear life

AI-driven tool wear prediction

Hybrid carbide-ceramic blends for even tougher applications

Eco-friendly production to reduce carbon footprint

Suppliers that invest in R&D will offer tools that keep you ahead in both industrial and scientific machining.

Reflexiones finales

Whether you’re cutting aircraft alloys or preparing research samples, tungsten carbide cutting tools give you the performance, accuracy, and durability your work demands.

Their wear resistance, high-speed capability, and precision make them the backbone of both industrial and scientific applications.

By choosing the right tools, coatings, and supplier, you’re not just cutting metal—you’re cutting costs, saving time, and improving results.

Looking for top-quality carbide tools for your workshop or lab? Visit Retopz to find a full range of reliable, high-performance solutions.