The oilfield and petrochemical industries run some of the most demanding systems in the world.

Pumps, compressors, valves, and drilling equipment must work under high pressure, heat, and corrosive fluids.

A failure in sealing systems can lead to downtime, safety risks, and financial loss. This is why many companies choose tungsten carbide seal rings.

This article explains how anillos de sellado de carburo de tungsteno perform in oilfield and petrochemical applications, their unique properties, and why they are the best option for long-term reliability and cost savings.

Why Seal Rings Matter in Oilfield and Petrochemical Equipment

Seal rings are critical in protecting equipment against:

Leakage of petróleo, gas, or chemicals

Erosion from abrasive particles

Estrés térmico por altas temperaturas

Choque mecánico por cambios repentinos de presión

A strong, durable seal material ensures safety, compliance, and efficiency in these harsh environments.

Propiedades de los anillos de sellado de carburo de tungsteno

Tungsten carbide is a material created by combining tungsten and carbon, bonded with cobalt or nickel. Its main properties include:

Extremo dureza – Prevents wear from friction and abrasives.

High compressive strength – Withstands heavy pressure loads.

Thermal stability – Works reliably in hot oil and gas systems.

Resistencia a la corrosión – Resists hydrocarbons, seawater, and chemicals.

Long service life – Reduces replacement frequency.

These features make tungsten carbide the preferred sealing material in drilling rigs, refineries, and petrochemical plants.

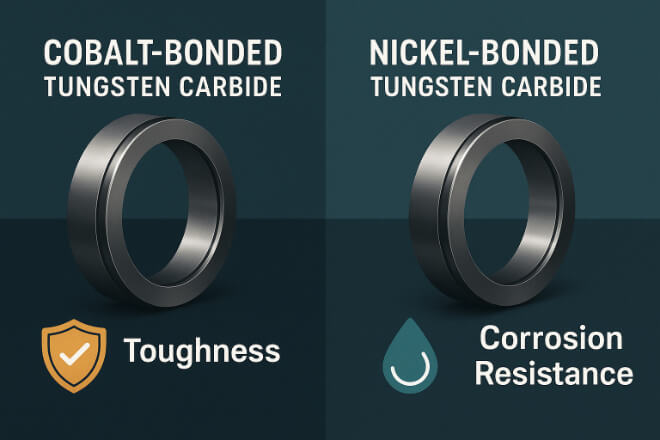

Carburo de tungsteno unido con cobalto vs. carburo de tungsteno unido con níquel

Binder choice affects performance:

1) Carburo de tungsteno unido con cobalto

Alto tenacidad, good for vibration and shock.

Best in oilfield compressors and drilling pumps.

Moderado Resistencia a la corrosión.

2) Carburo de tungsteno unido con níquel

Excellent resistance to corrosive chemicals.

Best for refineries and petrochemical plants.

Un poco menos resistente que el unido con cobalto.

Decision-makers must match the grade to the specific operating environment.

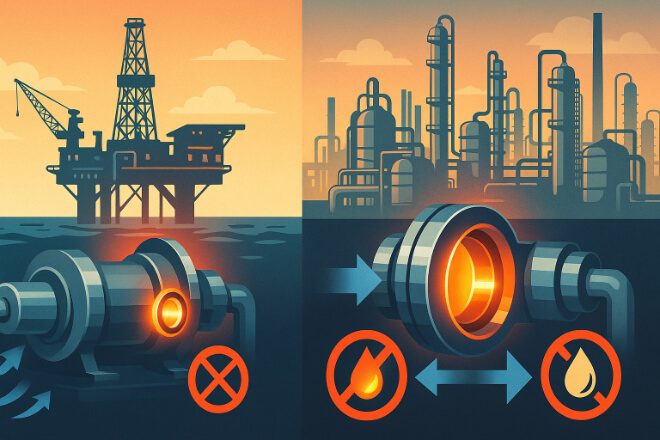

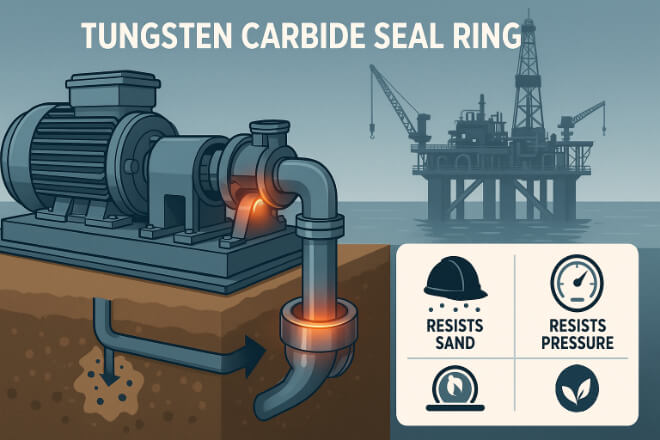

Performance in Oilfield Applications

In oilfield operations, seal rings face:

High-pressure crude petróleo y gas

Sand and abrasive particles in drilling fluids

Extreme temperature changes

Protect pumps and compressors from wear.

Prevent leakage that could cause safety issues.

Extend service life in drilling and production systems.

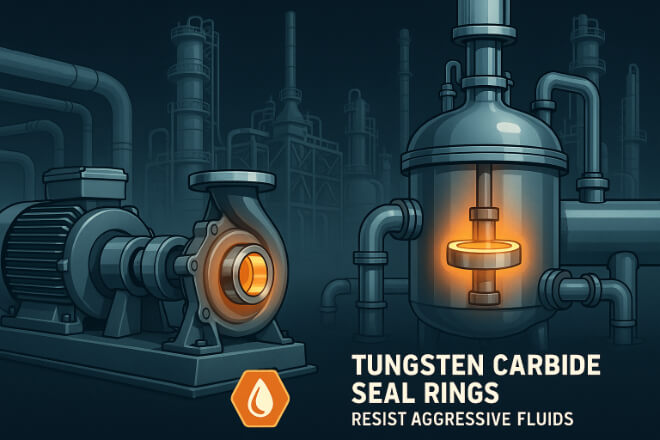

Performance in Petrochemical Applications

In petrochemical plants, seals face aggressive chemical exposure. Tungsten carbide seal rings:

Provide resistance against solvents, acids, and alkalis.

Work reliably in refinery pumps and chemical reactors.

Reduce downtime by lasting longer under corrosive conditions.

This makes them essential in facilities where chemical resistance is critical.

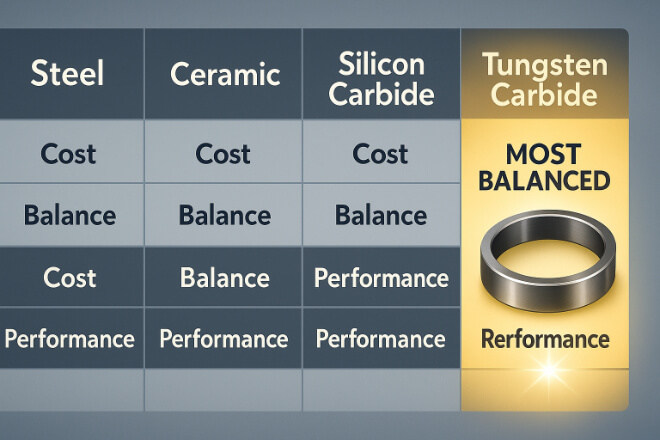

Comparación con otros materiales de sellado

Steel seals – Cheap but corrode quickly in oil and chemicals.

Ceramic seals – Chemically resistant but brittle under shock.

Silicon carbide – Strong against chemicals but less tough under impact.

Tungsten carbide – Best balance of strength, tenacidad, and chemical resistance.

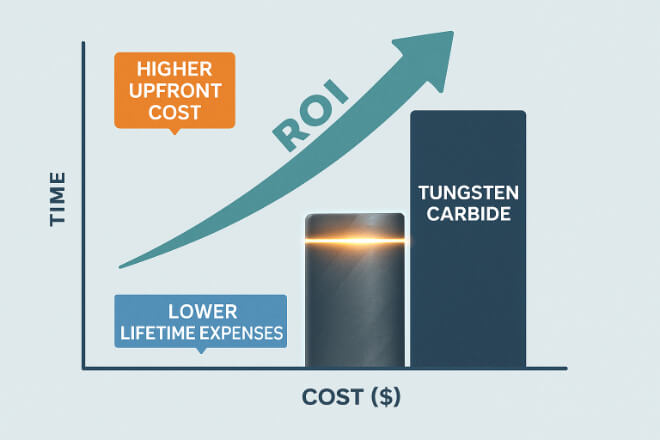

Costo vs. valor a largo plazo

Although tungsten carbide seal rings have a higher initial cost, their life cycle benefits outweigh the price:

Menos reemplazos → Menores costos de repuestos.

Menos tiempo de inactividad → Mayor productividad.

Longer pump life → Reduced equipment damage.

Mejor retorno de la inversión → Sólidos argumentos financieros para los responsables de la toma de decisiones.

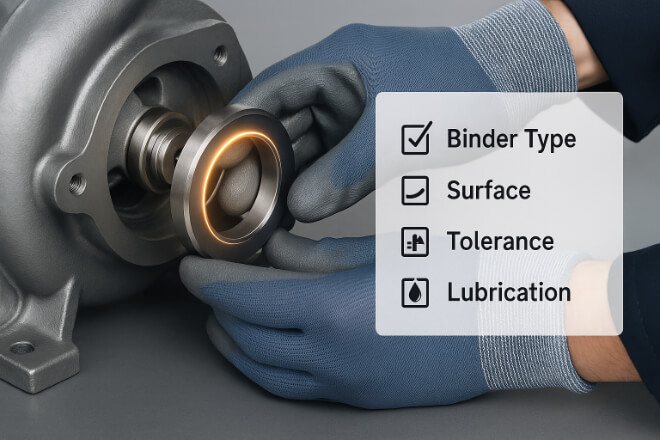

Mejores prácticas para el uso de anillos de sellado de carburo de tungsteno

To ensure maximum performance in oilfield and petrochemical systems:

Choose the right grade → Níquel para la corrosión, cobalto para los golpes.

Instalar con cuidado → Avoid scratches that weaken chemical resistance.

Inspeccionar regularmente → Detecte signos tempranos de desgaste o corrosión.

Mantener la lubricación → Reduces heat and friction damage.

Sostenibilidad y reciclaje

Tungsten carbide seal rings are recyclable. Many suppliers reclaim used rings and process them into new products.

This reduces waste and supports environmental goals, which is increasingly important in oil and petrochemical industries.

Conclusiones clave para los responsables de la toma de decisiones

Tungsten carbide seal rings are best for oilfield and petrochemical equipment.

They resist wear, pressure, heat, and corrosion.

Cobalt-bonded grades suit heavy loads and shock.

Nickel-bonded grades suit chemical-rich environments.

Higher upfront cost is offset by longer service life and fewer failures.

Conclusión

For oilfield and petrochemical applications, tungsten carbide seal rings are the most reliable choice. They handle harsh conditions, corrosive fluids, and heavy loads better than most alternatives.

For decision-makers, investing in tungsten carbide seal rings means safer operations, less downtime, and stronger long-term value.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.