Las herramientas de carburo de tungsteno son reconocidas por su excepcional dureza, resistencia al desgaste y capacidad para soportar condiciones de trabajo extremas. Pero este impresionante rendimiento no se limita al WC y al cobalto: también es el resultado de una cuidadosa selección de elementos de aleación. Estas adiciones de trazas pueden ser pequeñas en cantidad, pero tienen un gran impacto en el comportamiento, la durabilidad y el control de la microestructura de la herramienta.

Este artículo explora qué son los elementos de aleación, por qué se agregan y cómo afectan el rendimiento de las herramientas de carburo cementado.

¿Qué son los elementos de aleación?

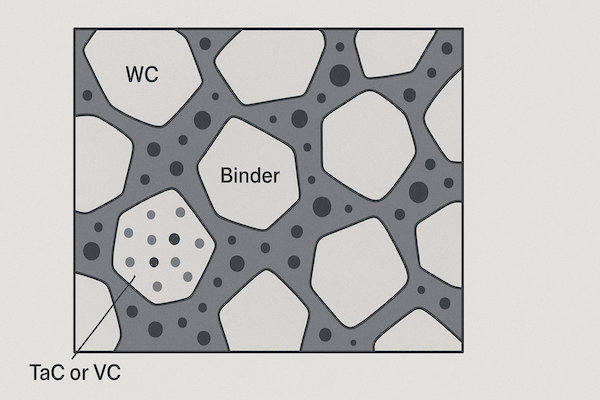

En la ciencia de los materiales, los elementos de aleación son elementos que se añaden intencionalmente en pequeñas cantidades a un metal base o a un compuesto para modificar sus propiedades. En el caso del carburo de tungsteno, que suele estar compuesto por granos de WC unidos con un aglutinante metálico (generalmente cobalto o níquel), se añaden elementos de aleación al aglutinante o fase de WC para mejorar características específicas.

Los elementos de aleación comunes en herramientas basadas en WC incluyen:

Vanadio (V)

Cromo (Cr)

Tantalio (Ta)

Titanio (Ti)

Niobio (Nb)

Molibdeno (Mo)

Estos elementos normalmente se introducen en forma de carburos, como VC, Cr₃C₂, TaC, TiC o NbC.

¿Por qué se utilizan elementos de aleación en los carburos cementados?

Los elementos de aleación no se añaden al azar: cumplen funciones específicas, entre ellas:

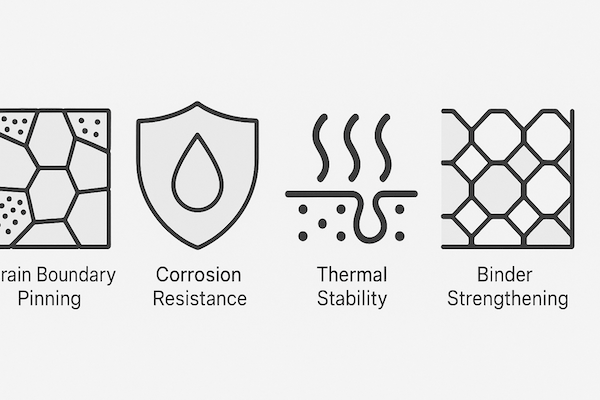

🔹 Inhibición del crecimiento del grano

Durante la sinterización, los granos de WC tienden a crecer. El carburo de vanadio (VC) y el carburo de cromo (Cr₃C₂) se utilizan para fijar los límites de grano, evitando el crecimiento excesivo y manteniendo la estructura fina del grano, lo que mejora la calidad. dureza y resistencia al desgaste.

🔹 Resistencia a la corrosión mejorada

El cromo (Cr) y el molibdeno (Mo) mejoran la capacidad del aglutinante para resistir el ataque químico, lo que es especialmente importante en entornos químicos agresivos o ricos en humedad.

🔹 Mayor estabilidad a altas temperaturas

Los elementos de aleación como el tantalio (Ta) y el titanio (Ti) aumentan la dureza en caliente de la herramienta, lo que le permite mantener la resistencia y la estructura a altas temperaturas de corte.

🔹 Fortalecimiento de la fase aglutinante

Ciertos elementos pueden fortalecer el aglutinante de Co o Ni, aumentando así la resistencia general. tenacidad y haciendo que la herramienta sea menos propensa a agrietarse o astillarse.

Efectos microestructurales de los elementos de aleación

Los elementos de aleación influyen en la fase de carburo, la fase aglutinante y la interfaz WC/aglutinante. Su distribución puede dar lugar a:

Formación de carburos complejos que mejoran la estabilidad del filo.

Control sobre el camino libre medio entre granos de WC

Microestructuras uniformes con defectos mínimos

Un control adecuado de las adiciones de aleación da como resultado un equilibrio optimizado entre tenacidad y dureza, una vida útil más prolongada de la herramienta y una mayor personalización específica de la aplicación.

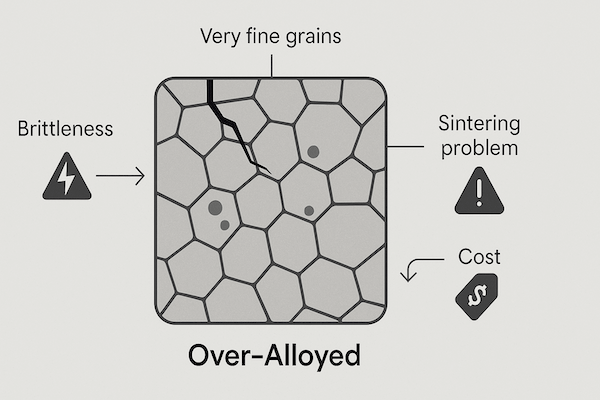

¿Demasiado de algo bueno?

Si bien los elementos de aleación son beneficiosos, las cantidades excesivas pueden provocar:

Tenacidad reducida (debido a granos demasiado finos)

Mayor fragilidad

Polvos difíciles de sinterizar

Aumentos de costos

Por eso es esencial una formulación precisa y un control de I+D.

Conclusión

Los elementos de aleación son los ingenieros silenciosos detrás del rendimiento de herramientas de carburo de tungsteno. Desde el control microestructura Para mejorar Resistencia a la corrosión y la estabilidad térmica, desempeñan un papel fundamental en la adaptación de herramientas para entornos extremos y aplicaciones exigentes.

Ya sea que estés en minería, mecanizado, aeroespacial, o petróleo y gasComprender cómo funcionan los elementos de aleación le ayudará a apreciar la ciencia de la ingeniería detrás de cada herramienta de carburo.