In modern industrial machinery, every small part affects the performance of the entire system.

Among these parts, bujes de carburo de tungsteno play a key role in reducing friction, supporting rotating shafts, and extending the life of pumps, compressors, and turbines.

However, not all carbide bushings are made equal. The quality of a tungsten carbide bushing depends on several factors — from the purity of its raw materials to the precision of its grinding and finishing.

Poor-quality bushings may wear quickly, cause vibration, or lead to unplanned equipment downtime.

This article explains the major factors that determine the quality, performance, and reliability of tungsten carbide bushings and what decision-makers should look for when evaluating suppliers.

Material Composition and Purity

The base materials used in manufacturing are the foundation of any carbide product’s quality.

A typical tungsten carbide bushing is made of tungsten carbide grains (WC) bonded with a metallic binder such as cobalt (Co) or nickel (Ni).

| Tipo de carpeta | Ventaja principal | Best Used In |

|---|---|---|

| Cobalto (Co) | High toughness and fatigue resistance | Oilfield and mechanical pumps |

| Níquel (Ni) | Resistencia superior a la corrosión | Chemical, seawater, or acidic media |

Purity of the polvo de carburo de tungsteno and consistency in binder ratio (typically 6–12%) directly affect the final bushing’s dureza, Resistencia a la corrosión, and dimensional stability.

High-quality bushings always use refined WC powders with tight grain-size control and low impurity levels, ensuring uniform microstructure throughout the component.

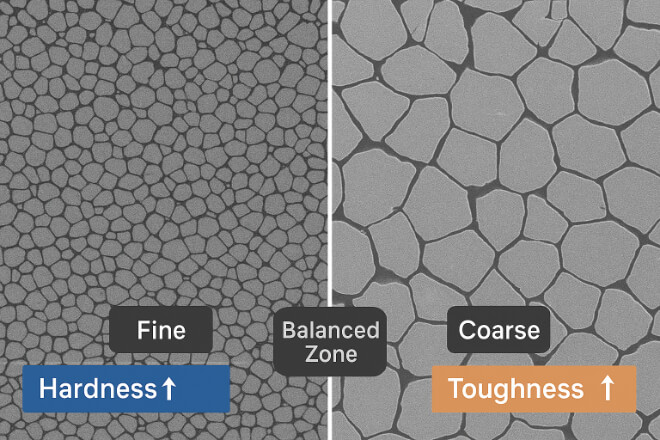

Grain Size and Microstructure

Grain size determines the balance between dureza y tenacidad.

Fine-grain carbide (0.5–1.0 µm) offers superior wear resistance, while coarse-grain types (2–5 µm) provide higher impact strength.

| Grain Type | Typical Hardness | Typical Toughness | Recommended Use |

|---|---|---|---|

| Fine-Grain (0.5–1 µm) | High (90–92 HRA) | Medio | Precision pumps and turbines |

| Medium-Grain (1–3 µm) | Balanced (88–90 HRA) | Bien | General-purpose mechanical systems |

| Coarse-Grain (3–5 µm) | Lower (85–87 HRA) | Alto | Heavy-load industrial pumps |

Consistent and homogeneous grain structure ensures that the bushing wears evenly and does not crack under pressure or vibration.

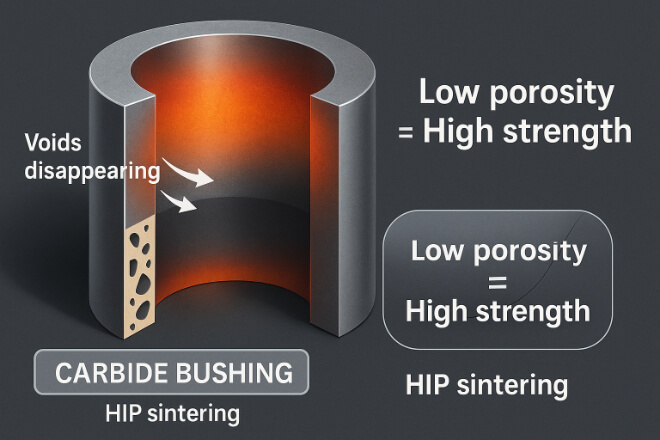

Density and Porosity

El densidad of a tungsten carbide bushing indicates how well the material was sintered.

High-quality bushings show minimal porosidad, meaning fewer microscopic voids that could become weak points or leak paths.

Porosity is measured and classified during inspection. Bushings with porosity less than 0.5% provide maximum strength and reliability, especially in high-pressure or high-speed applications.

Low-porosity parts also resist corrosion better because fewer pores mean less surface area for fluid penetration.

Dimensional Accuracy and Tolerance

Even the strongest material is useless if it does not fit correctly.

Tungsten carbide bushings require precision machining and tight tolerances to perform properly in mechanical assemblies.

Typical tolerance classes for high-quality bushings include:

Inner diameter (ID): ±0.002 mm

Outer diameter (OD): ±0.003 mm

Roundness/flatness: ≤0.001 mm

Precision control prevents shaft misalignment and vibration — two major causes of premature bearing and seal failure.

Surface Finish and Lapping Quality

The surface finish (Ra value) directly influences lubrication, friction, and wear rate.

A well-lapped tungsten carbide bushing should have a mirror-like finish with Ra between 0.04–0.05 µm.

Poorly polished or uneven surfaces cause fluid turbulence, heat buildup, and micro-abrasion.

Lapping and polishing processes must be done with controlled pressure and fine diamond slurry to achieve this smoothness without distorting the geometry.

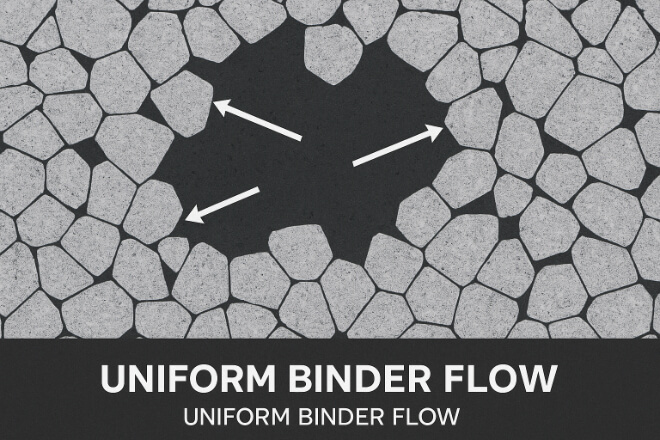

Binder Distribution and Phase Control

Uniform distribution of the metallic binder (Co or Ni) throughout the microstructure is essential.

Uneven binder pools can cause weak zones, cracks, or inconsistent hardness.

Advanced manufacturers use HIP (Hot Isostatic Pressing) to eliminate internal voids and ensure even binder flow.

This improves both strength and thermal shock resistance, resulting in longer bushing life under heavy loads and high temperatures.

Inspection and Quality Testing

| Test Type | Objetivo | Quality Indicators |

|---|---|---|

| Hardness Test | Checks resistance to wear | 88–92 HRA |

| Density Test | Confirms proper sintering | ≥14.9 g/cm³ |

| Análisis de microestructura | Verifies uniform grain size | No clustering or voids |

| Flatness Test | Ensures proper contact surface | ≤0.3 µm deviation |

These inspection results separate top-tier bushings from low-cost alternatives.

Buyers should always ask suppliers for test certificates and inspection reports.

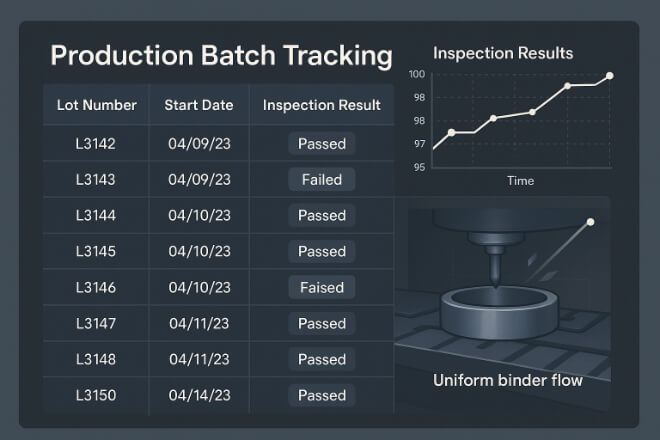

Manufacturing Consistency and Traceability

The best carbide manufacturers maintain strict process control and full batch traceability.

Consistency between batches ensures that performance remains predictable across multiple production runs.

Traceability includes documentation of:

Powder source and lot number

Sintering and HIP cycle data

Final inspection results

Having this data allows users to identify trends, confirm material quality, and reduce the risk of unexpected performance variation.

Supplier Expertise and Certification

Finally, the experience and quality management system of the manufacturer play a major role.

Suppliers who specialize in carbide manufacturing and operate under ISO 9001 or similar quality systems offer higher reliability and repeatability.

A capable supplier will also provide:

Technical consultation for grade selection

Customized bushing geometries

Surface finishing options (polished, lapped, honed)

Fast delivery and after-sales support

For critical applications like high-speed pumps or turbine shafts, choosing a certified supplier is just as important as the material itself.

Conclusión

The quality of tungsten carbide bushings depends on far more than just the raw material.

It’s determined by a careful balance of composition, grain control, density, machining precision, surface finish, and quality testing.

For decision-makers, investing in higher-quality carbide bushings means fewer failures, longer service intervals, and better overall equipment reliability.

In short, high-quality bushings don’t just perform better — they protect your bottom line.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.