In modern machining, tool wear is one of the biggest challenges. When tools wear out too fast, it leads to poor finishes, slower production, and higher costs.

That’s why wear resistance matters—and this is where herramientas de corte de carburo de tungsteno truly shine.

Tungsten carbide is not just another tool material. It’s one of the hardest and most wear-resistant materials available, making it perfect for tough machining jobs.

But what exactly makes it so durable? And how does it outperform traditional tool materials like high-speed steel?

This article breaks it down in simple terms. Whether you’re running a CNC machine shop or working with difficult materials, we’ll show you why tungsten carbide tools are the smart choice for long-lasting performance.

1. What Is Wear Resistance in Cutting Tools?

Resistencia al desgaste is the ability of a cutting tool to stay sharp and functional after extended use. When a tool cuts metal, plastic, or wood, its edges face:

Heat

Fricción

Pressure

Abrasive materials

Over time, this causes the tool to dull, chip, or break. Tools with poor wear resistance lose accuracy and cause defects in your parts.

With good wear resistance:

The tool lasts longer

The surface finish stays clean

You reduce downtime and replacement costs

This is why wear resistance is one of the most important factors when choosing cutting tools.

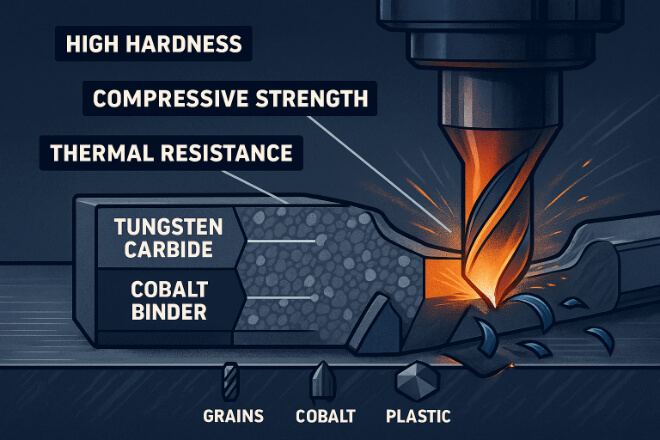

2. What Makes Tungsten Carbide So Wear Resistant?

Tungsten carbide is a compound made of tungsten and carbon, combined with a metal binder like cobalt.

Together, they form a dense, extremely hard material that resists wear much better than regular tool steels.

Here are the main reasons why it performs so well:

1). High Dureza

Tungsten carbide is twice as hard as steel

It ranks about 9 on the Mohs scale, just below diamonds

This hardness allows it to cut through tough materials without dulling

2). Excellent Compressive Strength

Can withstand very high cutting forces

Doesn’t deform easily under pressure

3). High Thermal Resistance

Maintains hardness even at high temperatures

Can cut at faster speeds without softening

4). Low Wear Rate

The fine grain structure resists abrasion from hard chips and surfaces

Keeps edges sharper for longer periods

All of these properties make tungsten carbide the ideal material when tool wear is a concern.

3. Types of Tool Wear Tungsten Carbide Can Resist

There are different kinds of wear that tools face during cutting. Tungsten carbide tools are built to handle them all:

| Tipo de desgaste | Descripción | Carbide Resistance |

|---|---|---|

| Desgaste abrasivo | Chips rub against the tool surface | Excelente |

| Desgaste del adhesivo | Material sticks to the tool edge | Muy bien |

| Desgaste por difusión | Heat causes material loss at the edge | Excelente |

| Chemical Wear | Reaction between tool and workpiece | Fuerte |

| Astillado de bordes | Cutting edge breaks under pressure | High Toughness (with right grade) |

4. Comparison: Tungsten Carbide vs. High-Speed Steel (HSS)

Let’s compare how carbide tools stack up against traditional high-speed steel (HSS) when it comes to wear resistance.

| Propiedad | Carburo de tungsteno | Acero de alta velocidad |

|---|---|---|

| Dureza | 1600–1800 HV | 600–900 HV |

| Resistencia al calor | Excelente | Moderado |

| Resistencia al desgaste | Superior | Moderado |

| Vida útil de la herramienta | 3–10 veces más largo | Más corto |

| Ideal Use Cases | Hard, abrasive materials | Softer metals, low-speed cuts |

So while HSS is cheaper, it wears out faster. That means more tool changes, more downtime, and higher total cost.

5. Real Benefits of Carbide’s Wear Resistance in Your Workshop

Here’s what better wear resistance actually means for your daily operations:

1) Mayor vida útil de la herramienta

You don’t have to replace carbide tools as often. This reduces tooling costs and increases productivity.

2). Better Surface Finish

Sharp edges last longer, which means cleaner cuts and smoother part surfaces—even over long production runs.

3). Higher Cutting Speeds

Because carbide resists heat better, you can run your machines faster without hurting tool life.

4). Improved Precision

Worn tools lead to dimensional inaccuracy. Carbide tools stay consistent, ensuring parts stay in spec.

5). Fewer Tool Changes

Less downtime, fewer interruptions, and better efficiency for your CNC operators.

6. What Industries Rely on Carbide’s Wear Resistance?

Tungsten carbide tools are used in any industry where cutting hard or abrasive materials is required. Here are some common sectors:

1). Aeroespacial

Cutting titanium, Inconel, and high-strength steels

Long tool life reduces expensive downtime

2). Automotor

High-speed machining of hardened steel and cast iron

Consistent accuracy in engine and brake parts

Micro-tools for implants and surgical components

Sharpness and wear resistance ensure safety and precision

4). Petróleo y gas

Tools for drilling, pipe threading, and valve machining

Handles abrasive materials and extreme conditions

Carbide-tipped saw blades and router bits

Great for MDF, particle board, and fiberglass

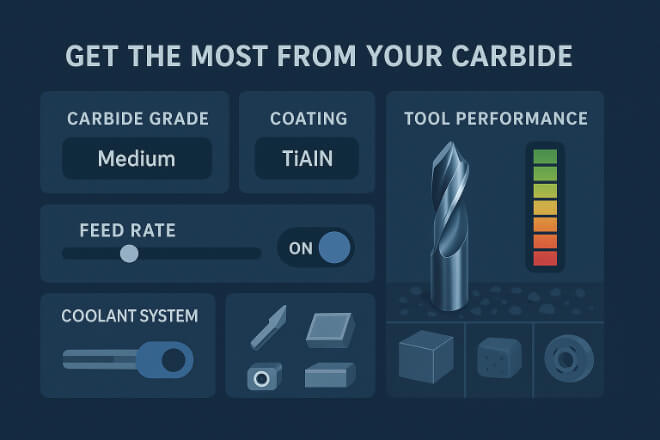

7. Factors That Affect Carbide Wear Resistance

Even though carbide is naturally wear-resistant, several factors can improve or reduce its performance:

1). Carbide Grade

Ultra-fine grain for wear resistance in finishing tools

Coarser grades for roughing and impact resistance

2). Tool Coating

TiAlN, AlCrN, and DLC coatings reduce friction and heat

Protect the tool surface and extend life

3). Feed & Speed

Running tools at proper speeds prevents edge breakdown

Higher speeds work well with carbide but must be controlled

4). Coolant and Lubrication

Helps reduce heat and wash away chips

Improves tool life significantly

8. Is Carbide Worth the Investment?

Some people hesitate to switch to carbide tools because of the higher price. But when you factor in wear resistance, they’re often the better value.

Vamos a desglosarlo:

| Factor | HSS Tool | Carbide Tool |

|---|---|---|

| Costo inicial | Bajo | Más alto |

| Vida útil de la herramienta | Short (1–3 hrs) | Long (10–20+ hrs) |

| Acabado de la superficie | Moderado | Excelente |

| Number of Replacements | Many | Few |

| Downtime | Frequent | Rare |

| Cost Per Part | Higher (indirect) | Más bajo |

Bottom Line: Carbide tools pay for themselves by lasting longer, working faster, and reducing rework.

Reflexiones finales

Tungsten carbide cutting tools stand out for one simple reason—they last longer.

With their exceptional wear resistance, they help machine shops and manufacturers save money, produce better parts, and boost efficiency.

If you’re tired of worn-out tools slowing down your production, it’s time to make the switch. Tungsten carbide isn’t just stronger—it’s smarter.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.