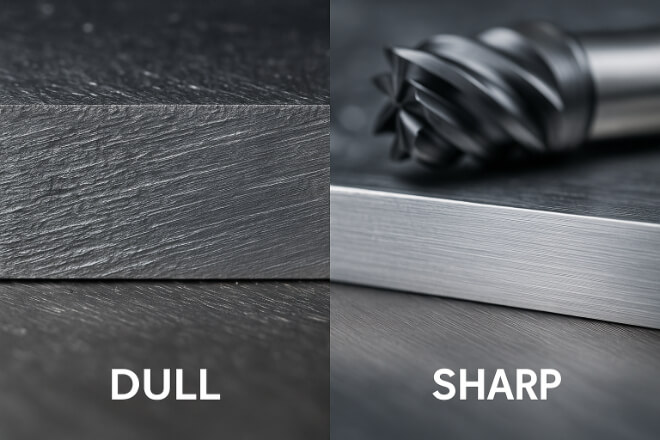

Signes qu'il est temps de remplacer vos outils de coupe en carbure de tungstène

Les outils de coupe en carbure de tungstène sont réputés pour leur résistance et leur longévité. Mais comme tout outil, ils finissent par s'user. Utiliser un outil émoussé ou endommagé peut endommager votre pièce, ralentir vos machines et même causer des problèmes plus graves. Si vous dirigez un atelier ou assurez le bon fonctionnement de la production, savoir quand changer […]

Pourquoi choisir le bon fournisseur d'outils de coupe en carbure de tungstène est important

Dans le monde de l'usinage de précision et de la fabrication industrielle, les outils de coupe en carbure de tungstène jouent un rôle essentiel. Ces outils sont reconnus pour leur dureté, leur résistance à l'usure et leur capacité à supporter des coupes à grande vitesse dans des matériaux durs. Mais un facteur clé est négligé par de nombreux décideurs : le fournisseur de l'outil. Choisir le bon fournisseur pour votre […]

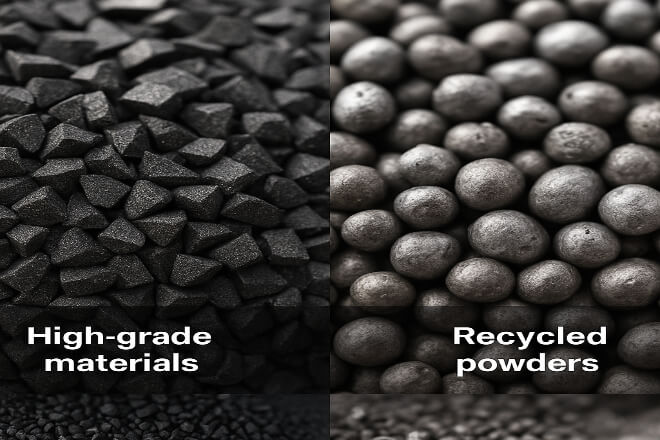

Facteurs affectant le coût des outils de coupe en carbure de tungstène

Les outils de coupe en carbure de tungstène sont essentiels dans de nombreux secteurs, de l'automobile et de l'aéronautique à la fabrication de moules et à l'usinage général. Ces outils sont réputés pour leur robustesse, leur résistance à la chaleur et leur longue durée de vie. Cependant, une question récurrente des équipes d'achat et des décideurs est : pourquoi les outils en carbure de tungstène coûtent-ils si cher ? Comprendre le prix de ces outils est essentiel […]

Mythes courants sur les outils de coupe en carbure de tungstène démystifiés

Les outils de coupe en carbure de tungstène sont largement utilisés dans des secteurs comme l'aéronautique, l'automobile et la fabrication générale. Ils sont réputés pour leur robustesse, leur précision et leur capacité à couper des matériaux durs. Cependant, de nombreuses idées fausses persistent quant à leur fonctionnement, leur durée de vie et leur prix. Ces mythes conduisent souvent à de mauvais choix d'achat […]

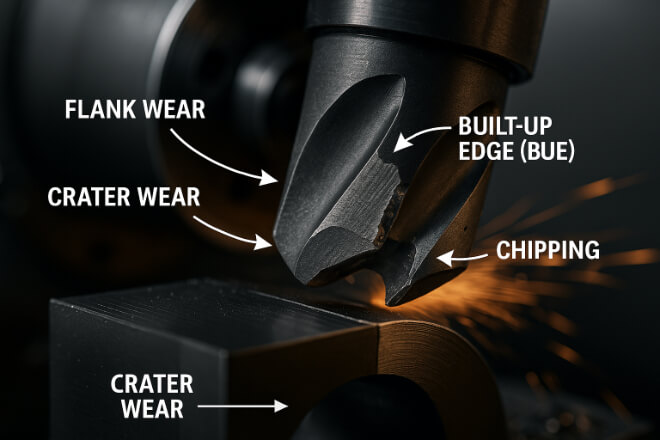

Comment réduire l'usure des outils avec des outils de coupe en carbure de tungstène

Les outils de coupe en carbure de tungstène sont reconnus dans de nombreux secteurs pour leur robustesse, leur précision et leur durabilité. Cependant, même les outils les plus robustes s'usent avec le temps. Pour les décideurs des entreprises d'usinage et de fabrication, réduire l'usure des outils n'est pas seulement un défi technique, c'est une décision commerciale judicieuse. Moins d'usure signifie des coûts réduits, une meilleure productivité et moins d'interruptions. […]

Découpe de précision au carbure de tungstène : bonnes pratiques et conseils

Pour des coupes nettes et précises en usinage, les outils en carbure de tungstène sont souvent la solution idéale. Ils sont plus durs que l'acier rapide, plus résistants à la chaleur et offrent de meilleures performances dans les applications à grande vitesse. Mais posséder un outil en carbure ne suffit pas : il faut aussi l'utiliser correctement. Dans ce guide, nous vous expliquerons […]

L'impact environnemental de l'utilisation d'outils de coupe en carbure de tungstène

Aujourd'hui, le développement durable est plus que jamais une préoccupation majeure. Des choix personnels aux opérations industrielles, chacun s'efforce de réduire les déchets, d'économiser l'énergie et de prendre de meilleures décisions pour la planète. Mais lorsqu'il est question d'usinage et de fabrication, l'impact environnemental est souvent négligé. C'est là qu'interviennent les outils coupants en carbure de tungstène. […]

Comment identifier les outils de coupe en carbure de tungstène de qualité

Lorsque vous travaillez avec des machines CNC ou toute autre application de haute précision, le choix des outils peut influencer vos résultats. Les outils de coupe en carbure de tungstène sont populaires car ils sont robustes, durables et parfaits pour l'usinage à grande vitesse. Cependant, tous les outils en carbure ne se valent pas. Dans ce guide, nous vous expliquerons comment déterminer si un […]

Le rôle des revêtements dans l'amélioration des performances des outils de coupe en carbure de tungstène

Les outils de coupe en carbure de tungstène sont réputés pour leur robustesse et leur durabilité. Cependant, même les outils les plus résistants peuvent s'user rapidement dans des conditions extrêmes. C'est là que les revêtements entrent en jeu. Appliquer le bon revêtement peut faire toute la différence sur la durée de vie de votre outil, sa qualité de coupe et vos économies […]

Problèmes courants et solutions avec les outils de coupe en carbure de tungstène

Les outils de coupe en carbure de tungstène sont réputés pour leur dureté et leur longue durée de vie. Ils sont souvent utilisés dans l'usinage CNC, l'aéronautique, l'automobile et de nombreuses autres industries de haute précision. Cependant, même ces outils robustes peuvent rencontrer des problèmes s'ils ne sont pas utilisés ou entretenus correctement. Dans cet article, nous examinerons les problèmes les plus courants […]