Joints d'étanchéité en carbure de tungstène dans les équipements d'énergie renouvelable

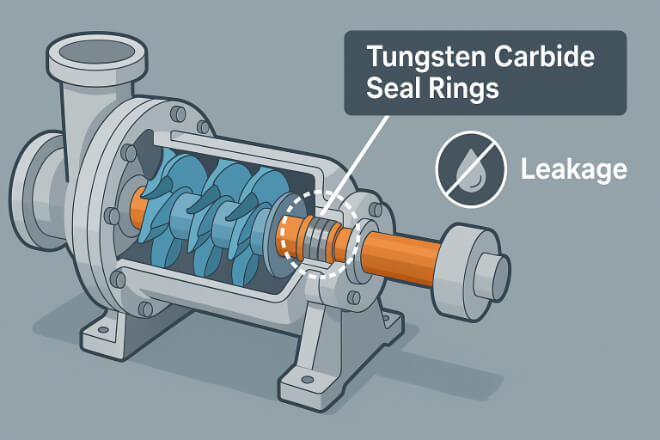

Les systèmes d'énergie renouvelable, tels que les éoliennes, les centrales hydroélectriques, les parcs solaires avec pompes et les systèmes géothermiques, fonctionnent dans des conditions environnementales difficiles. Leurs composants doivent fonctionner pendant des années avec un minimum de maintenance pour maintenir une production énergétique efficace et rentable. Le joint d'étanchéité est un composant essentiel. Dans les pompes, les turbines et les compresseurs, les joints empêchent les fuites de fluide, protègent les roulements et assurent […]

Choisir des joints d'étanchéité en carbure de tungstène pour les milieux chimiques agressifs

Les usines chimiques, les raffineries, les systèmes marins et les centrales électriques manipulent souvent des fluides chimiques agressifs, hautement corrosifs ou abrasifs. Les joints d'étanchéité des pompes, compresseurs et turbines doivent résister à ces conditions difficiles sans fuite ni défaillance. Les joints d'étanchéité en carbure de tungstène sont l'une des solutions les plus fiables. Cet article explique leurs avantages et comment choisir le bon […]

Bagues d'étanchéité en carbure de tungstène pour compresseurs et turbomachines

Les compresseurs et turbomachines sont essentiels dans des secteurs tels que le pétrole et le gaz, la chimie, la marine et la production d'énergie. Ces machines fonctionnent sous haute pression, chaleur et vibrations, et la moindre défaillance d'un joint peut entraîner des temps d'arrêt coûteux et des risques pour la sécurité. Pour garantir des performances fiables, de nombreuses entreprises optent pour des joints d'étanchéité en carbure de tungstène. Cet article […]

Avantages environnementaux de l'utilisation de bagues d'étanchéité en carbure de tungstène

Les industries telles que le pétrole et le gaz, la marine, la chimie et la production d'énergie sont contraintes de réduire leur impact environnemental. Chaque composant des équipements industriels, y compris les systèmes d'étanchéité, peut influencer le développement durable. Un matériau se distingue par ses performances et ses avantages environnementaux : les joints d'étanchéité en carbure de tungstène. Cet article explique les avantages environnementaux de l'utilisation de ces joints, […]

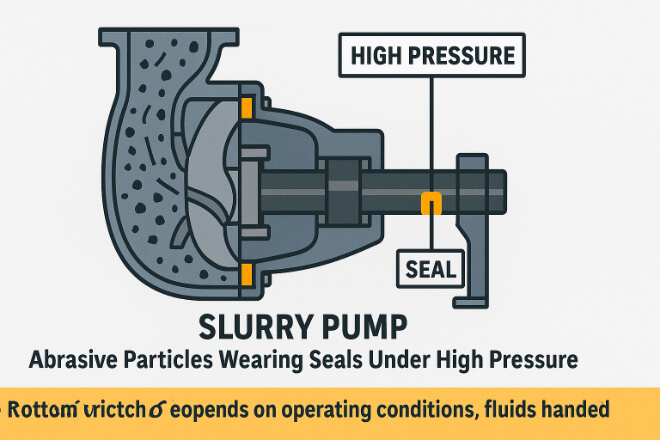

Bagues d'étanchéité en carbure de tungstène pour la manipulation de boues et de fluides abrasifs

Les fluides liquides et abrasifs comptent parmi les matériaux les plus difficiles à utiliser pour les pompes, mélangeurs et turbines industriels. Ces fluides contiennent des particules solides telles que du sable, du limon ou des minéraux, qui peuvent rapidement endommager les équipements. Un système d'étanchéité fiable est essentiel pour prévenir les fuites, réduire la maintenance et assurer le bon fonctionnement des opérations. Parmi les matériaux disponibles, le carbure de tungstène […]