Quand les entreprises choisissent pièces d'usure en carbure de tungstène, ils se concentrent souvent sur dureté, dureté, et le coût. Mais un facteur est souvent négligé : la taille des grains.

La taille des grains de carbure de tungstène dans la microstructure a un effet direct sur la résistance à l'usure, la ténacité et la durée de vie de la pièce.

Pour les décideurs dans des secteurs comme exploitation minière, pétrole et gaz, travail des métaux, et la fabrication, il est important de comprendre la granulométrie. Cela permet de choisir la nuance de carbure adaptée à chaque application, en équilibrant performances et coût.

Cet article explique comment la taille des grains influence les performances d'usure du carbure, pourquoi c'est important et comment les entreprises peuvent utiliser ces connaissances pour prendre de meilleures décisions d'achat.

Quelle est la taille des grains dans les matériaux en carbure ?

Le carbure de tungstène est fabriqué en combinant des grains de carbure durs avec un liant métallique (généralement du cobalt ou du nickel).

La taille des grains fait référence à la taille ou à la petitesse de ces particules de carbure dans la microstructure.

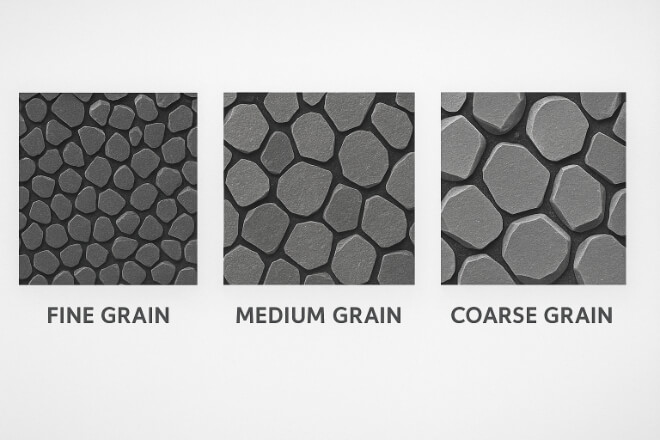

Carbure à grains fins : Les grains sont très petits, généralement inférieurs à 1 micron.

Carbure à grains moyens : grains entre 1 et 3 microns.

Carbure à gros grains : Grains supérieurs à 3 microns.

Le contrôle de la taille des grains pendant la fabrication permet aux ingénieurs de concevoir des nuances de carbure avec des propriétés spécifiques adaptées à différentes utilisations.

Pourquoi la taille des grains est importante pour la performance d'usure

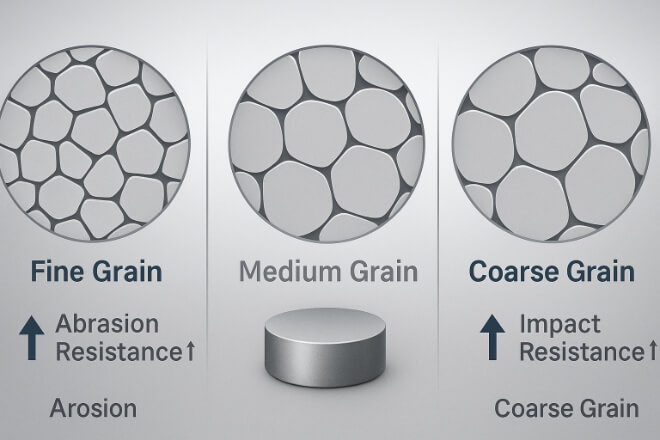

La taille des grains affecte l'équilibre entre dureté et dureté:

Le carbure à grains fins est plus dur et plus résistant à l’usure abrasive.

Le carbure à gros grains est plus résistant et moins susceptible de se fissurer sous un impact violent.

Le carbure à grain moyen offre un équilibre entre les deux.

Cela signifie que la taille des grains n’est pas seulement un détail technique : elle a un impact direct sur la durée de vie d’une pièce et sur la valeur qu’elle apporte à l’entreprise.

Carbure à grains fins : haute résistance à l'usure

Le carbure à grains fins est composé de très petites particules étroitement regroupées.

1). Avantages :

Haut dureté.

Excellente résistance à l'usure abrasive.

Peut obtenir des finitions de surface plus lisses.

Convient aux outils de précision tels que les plaquettes de coupe, les forets et les outils résistants à l'usure buses.

2). Limites :

Moins dureté, plus cassant sous un impact soudain.

Coût de production plus élevé par rapport aux grades grossiers.

Le carbure à grain fin est le meilleur lorsqu'il est abrasif résistance à l'usure est plus important que la résistance aux chocs.

Carbure à gros grains : haute ténacité

Le carbure à gros grains a des particules plus grosses, ce qui augmente la ténacité.

1). Avantages :

Haute résistance à la fissuration sous impact.

Fonctionne bien dans les applications lourdes et soumises à des chocs.

Coûts de production réduits.

2). Limites :

Inférieur dureté par rapport au carbure à grains fins.

S'use plus rapidement dans les environnements abrasifs.

Le carbure à gros grains est idéal pour les pics miniers, les outils de construction et les équipements de forage où les charges d'impact sont très élevées.

Carbure à grain moyen : performances équilibrées

Le carbure à grain moyen combine les avantages des nuances fines et grossières.

1). Avantages :

Flexible pour de nombreuses applications industrielles.

Choix économique pour les entreprises qui ont besoin de performances sans spécialisation extrême.

2). Limites :

Ce n’est pas la meilleure option pour les cas extrêmes d’abrasion ou d’impact.

Le carbure à grain moyen est souvent utilisé pour les pièces d'usure à usage général, telles que bagues, manchons, et les composants de la vanne.

Contrôle de la croissance des grains dans la fabrication

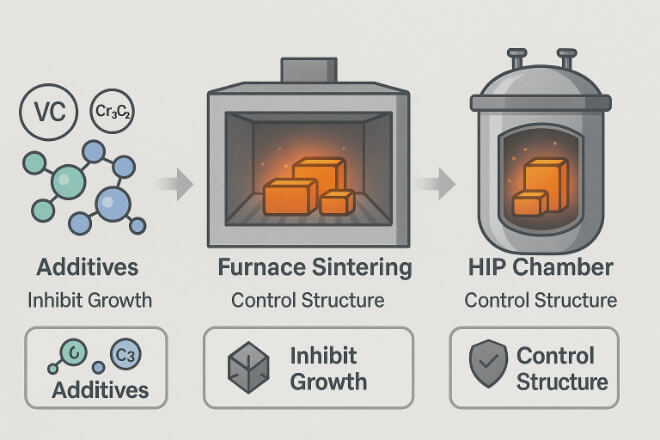

La granulométrie du carbure n'est pas une simple coïncidence. Elle est soigneusement contrôlée pendant la production grâce à des additifs et des ajustements de procédé.

Les méthodes comprennent :

Inhibiteurs de croissance des grains : Petites quantités de carbure de vanadium (VC) ou de carbure de chrome (Cr₃C₂) sont ajoutés pour garder les grains fins.

Température et durée de frittage : une chaleur plus élevée ou un frittage plus long peuvent faire grossir les grains.

HIP (Hot Isostatic Pressing) : Aide à améliorer densité tout en contrôlant la structure du grain.

En contrôlant la taille des grains, les fabricants peuvent concevoir des nuances de carbure adaptées à des industries et à des besoins spécifiques.

Coût et retour sur investissement du choix de la bonne granulométrie

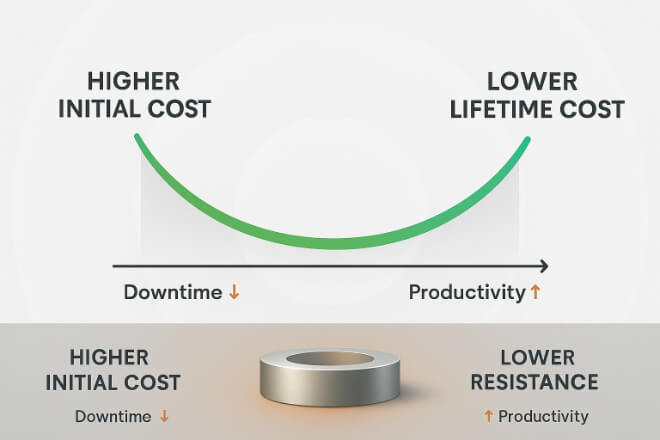

La sélection de la bonne granulométrie de carbure présente des avantages évidents en termes de coûts :

Moins de remplacements : une granulométrie appropriée signifie que les pièces durent plus longtemps dans des conditions spécifiques.

Temps d'arrêt réduits : les machines fonctionnent de manière plus fiable avec moins de pannes.

Productivité accrue : les performances correspondent aux besoins de l'application.

Meilleur retour sur investissement : le coût initial est compensé par une durée de vie plus longue et moins de perturbations.

Les décideurs qui prennent en compte la taille des grains lors de l’achat de pièces en carbure constatent souvent une baisse des coûts totaux au fil du temps.

Applications industrielles de différentes granulométries

Différentes industries bénéficient de différentes granulométries :

Exploitation minière et Construction : Carbure à gros grains pour outils exposés à de forts impacts.

Travail des métaux:Carbure à grain fin pour la coupe de plaquettes et de fraises.

Pétrole et gaz:Carbure à grain moyen pour bagues d'étanchéité, buses et pièces de vannes.

Travail du bois et Papier : Carbure à grain fin pour des lames tranchantes et durables.

Aérospatial et Automobile:Carbure à grain fin à moyen pour plus de précision et de durabilité.

Facteurs environnementaux et de durabilité

Choisir la bonne granulométrie est également bénéfique pour l’environnement :

Moins de déchets : des outils plus durables signifient moins de remplacements.

Efficacité énergétique : les machines consomment moins d’énergie lorsque les outils coupent efficacement.

Recyclage : Le carbure avec différentes granulométries peut toujours être recyclé et réutilisé.

Pour les entreprises axées sur la durabilité, l’optimisation de la granulométrie est un autre moyen de réduire l’impact environnemental tout en améliorant les performances.

Choisir le bon fournisseur de pièces d'usure en carbure

Tous les fournisseurs ne maîtrisent pas la granulométrie avec la même qualité. Lors de la sélection d'un fournisseur, les décideurs doivent vérifier :

Technologie avancée de R&D et de fabrication.

Expertise avérée dans le contrôle de la granulométrie.

Certifications ISO et assurance qualité.

Capacité à fournir des nuances de carbure personnalisées.

Un fournisseur solide garantit la bonne granulométrie pour chaque application, maximisant ainsi les performances et la rentabilité.

Conclusion

La granulométrie a un impact majeur sur la résistance à l'usure des pièces en carbure. Les grains fins offrent une meilleure résistance à l'usure, les grains grossiers une meilleure ténacité, et les grains moyens équilibrent les deux.

En comprenant et en choisissant la bonne granulométrie, les entreprises peuvent réduire les temps d’arrêt, améliorer la productivité et réduire les coûts.

Pour les industries où la fiabilité et le retour sur investissement sont essentiels, travailler avec un fournisseur qui comprend les effets de la taille des grains est la clé du succès.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.