In global industries, from bearings to valves and milling media, billes de carbure de tungstène play a vital role.

Because of their high dureté, résistance à l'usure, et densité, they are often preferred over steel or ceramic balls. However, the popularity of carbide balls has also created a problem: counterfeit products.

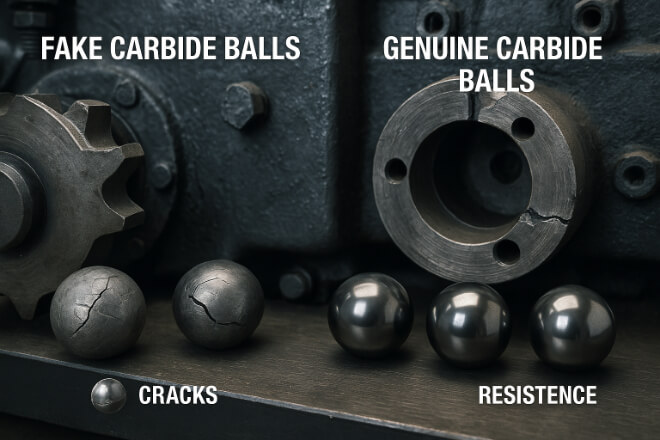

Fake carbide balls may look similar to real ones, but they often lack the required hardness, density, and durability.

Using counterfeit parts can lead to serious problems—equipment breakdown, higher downtime, and costly failures. For decision-makers, the ability to spot counterfeit carbide balls early is critical.

One of the most reliable ways to check authenticity is by looking at weight and density calculations. This article explains how to do that, along with other best practices.

Why Counterfeit Carbide Balls Are a Problem

Counterfeit balls are usually made from cheaper alloys or mixed materials.

These imitations might pass a quick visual inspection, but they fail under stress. Some of the risks include:

Premature wear and breakage in high-load environments.

Incorrect tolerances, leading to vibration or leakage in valves and pumps.

Reduced grinding efficiency in milling applications.

Safety hazards and expensive downtime.

For industries that depend on precision and durability, these risks are unacceptable.

Identifying genuine tungsten carbide is not just about quality—it’s about protecting your business.

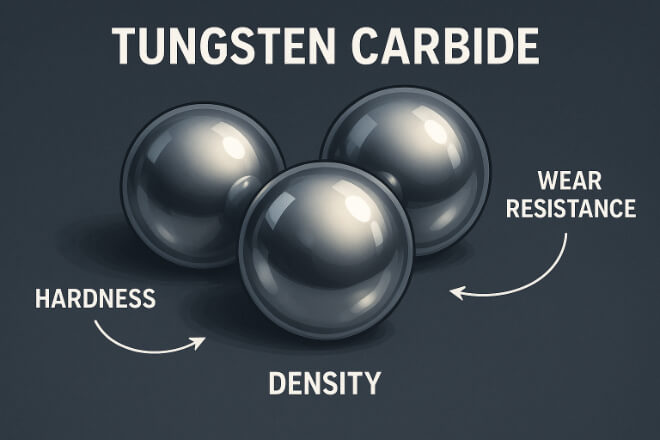

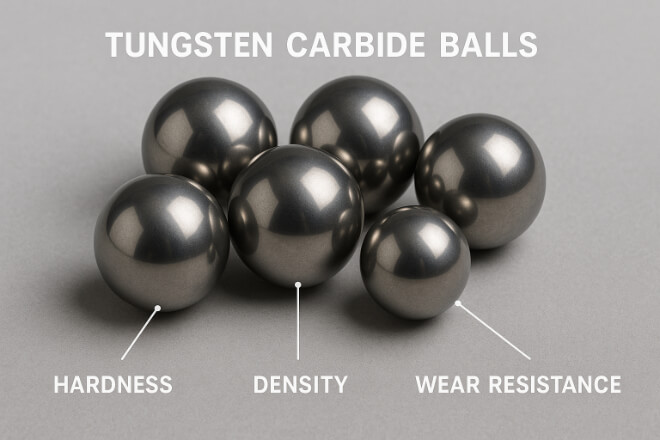

Key Properties of Genuine Tungsten Carbide Balls

Real tungsten carbide balls stand out because of their unique material properties:

Haut densité (around 14.5–15.1 g/cm³ depending on binder).

Extremely hard (close to 90 HRA on Rockwell scale).

Heavy weight for size, compared to steel or alloy balls.

Excellent wear and résistance à la corrosion.

These properties make tungsten carbide reliable under extreme loads, heat, and wear.

Counterfeits almost always show lower density and reduced hardness.

Step 1: Measure the Weight

Weighing is the easiest way to start. Use a precision scale that can measure small differences accurately.

Genuine tungsten carbide balls feel noticeably heavier than steel or stainless steel balls of the same size.

Par exemple:

A 10 mm tungsten carbide ball will weigh about 4.08 g.

A 10 mm steel ball will weigh about 4.10 g, but with lower density and strength.

Some counterfeit alloys may weigh less, around 3.5–3.8 g.

This simple check can alert you to suspicious parts before they enter production.

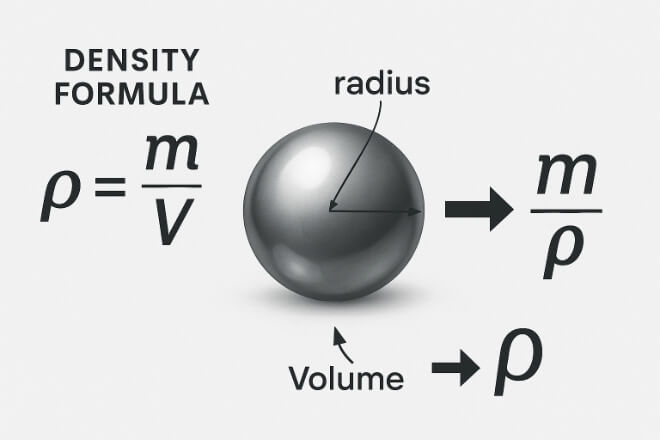

Step 2: Calculate the Density

Weight alone is not enough—densité confirms authenticity. Density is calculated as:

Density = Weight ÷ Volume

The volume of a ball can be calculated using the formula:

V = (4/3) × π × r³

Where r is the radius.

If the density falls in the range of 14.5–15.1 g/cm³, it is consistent with tungsten carbide.

Any major deviation—such as 7–8 g/cm³ (steel) or 5–6 g/cm³ (alloy)—indicates counterfeit material.

Step 3: Compare to Standard Reference Data

Industry suppliers often provide reference weight and density charts for standard ball sizes.

By comparing your measurements with these reference values, you can quickly spot inconsistencies.

Here is a simple HTML table showing reference weights for tungsten carbide balls:

| Ball Diameter (mm) | Expected Weight (g) | Expected Density (g/cm³) |

|---|---|---|

| 5 | 0.51 | 14.9 |

| 10 | 4.08 | 14.9 |

| 15 | 13.8 | 14.9 |

| 20 | 32.8 | 14.9 |

Step 4: Use Additional Tests

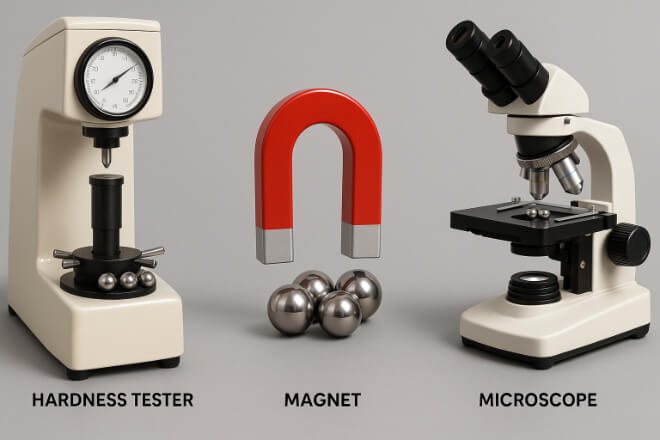

While weight and density are strong indicators, other tests add more certainty:

Magnetic test: Pure tungsten carbide is not strongly magnetic, while some counterfeits show strong magnetism.

Hardness test: Genuine carbide balls should exceed 85 HRA.

Visual inspection: High-quality carbide has smooth surfaces and precise tolerances.

A combination of checks gives the best assurance.

Step 5: Buy Only from Certified Suppliers

Even the best testing has limits. The most effective prevention is sourcing from trusted, certified suppliers. Look for companies that provide:

Material traceability certificates.

ISO quality management certification.

Independent hardness and density test reports.

Long-term reputation in carbide manufacturing.

Working with reliable suppliers reduces the chance of counterfeit products entering your supply chain.

Conclusion

Counterfeit tungsten carbide balls are a hidden risk for many industries. By applying simple checks—especially weight and density calculations—decision-makers can protect their equipment and reduce costly failures.

For critical applications in bearings, valves, milling media, and pumps, making sure you use genuine tungsten carbide is not just best practice—it’s essential for safety, performance, and cost savings.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.