Rotating equipment—such as pumps, compressors, turbines, and marine systems—is the backbone of many industries, including pétrole et gaz, chemical plants, marine operations, and power generation.

One of the biggest challenges in keeping this equipment running is seal failure. When seals fail, downtime increases, costs rise, and operations are put at risk.

This is why many companies choose bagues d'étanchéité en carbure de tungstène. Known for their durability and reliability, these rings help extend the life of mechanical seals and reduce downtime.

This article explains how tungsten carbide seal rings achieve this, and why they are a smart choice for decision-makers.

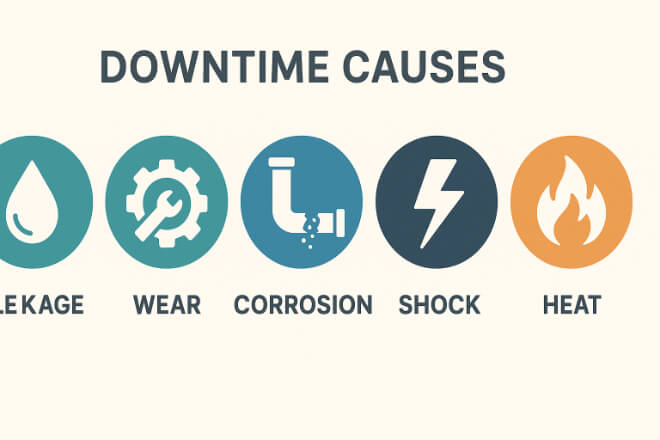

Why Downtime Happens in Rotating Equipment

Downtime often results from seal problems such as:

Leakage → Allowing oil, gas, or water to escape.

Usure et abrasion → Caused by friction or particles in fluids.

Corrosion → From chemicals or seawater.

Mechanical shock → Pressure spikes or sudden vibration.

Thermal stress → Heat causing distortion or material breakdown.

When seals fail, the entire system must stop for repairs, which can cost thousands per hour in lost production.

Propriétés des bagues d'étanchéité en carbure de tungstène

Tungsten carbide is made from tungsten and carbon, bonded with either cobalt or nickel. Its unique properties include:

Extrême dureté → Reduces wear from friction and abrasive fluids.

Haute résistance à la compression → Handles heavy loads without cracking.

Stabilité thermique → Maintains performance under high heat.

Résistance à la corrosion → Résiste à l’eau de mer, à l’huile et aux produits chimiques.

Stabilité dimensionnelle → Ensures a precise seal over long-term use.

These properties allow seals to survive longer in harsh environments, reducing downtime.

How Tungsten Carbide Seal Rings Reduce Downtime

1). Longer Service Life

Because tungsten carbide resists wear and corrosion, seals last longer before needing replacement, lowering unplanned downtime.

2). Reliability in Harsh Conditions

Seals continue to perform even under high temperature, high pressure, and corrosive environments, ensuring equipment stays online.

3). Shock Resistance

Cobalt-bonded tungsten carbide handles vibration and pressure spikes better than ceramics, preventing sudden failures.

4). Reduced Leakage

Tungsten carbide maintains tight sealing, reducing leakage that would otherwise cause performance loss or shutdown.

5). Lower Maintenance Frequency

Less frequent inspections and replacements mean more time in operation, less time offline.

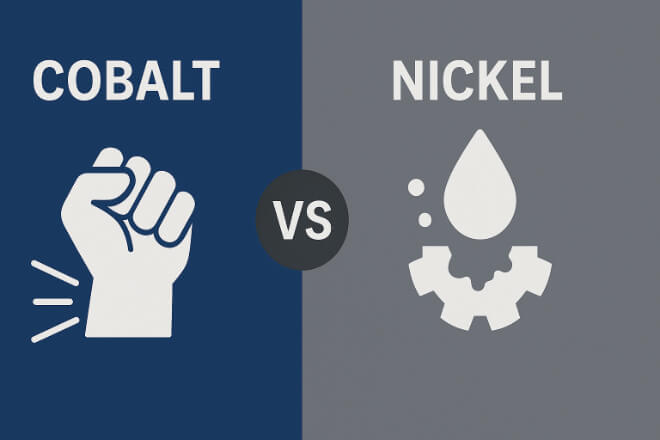

Nuances à liant cobalt et à liant nickel

1). Carbure de tungstène lié au cobalt

Best for shock resistance and vibration-heavy systems.

Used in pétrole et gaz compressors and mining pumps.

2). Carbure de tungstène lié au nickel

Best for corrosion resistance.

Used in chemical plants and marine systems.

Choosing the right binder ensures maximum uptime in the given application.

Comparaison avec d'autres matériaux d'étanchéité

Joints en acier → Corrode quickly, short life span.

Joints en céramique → Resist chemicals but brittle under impact.

Joints en carbure de silicium → Strong chemical resistance but less durable under shock.

Joints en carbure de tungstène → Balanced strength, durability, and résistance à l'usure and corrosion, making them the most reliable for uptime.

Applications in Rotating Equipment

Les bagues d'étanchéité en carbure de tungstène sont largement utilisées dans :

Pétrole et gaz compressors – Protect against wear in high-pressure drilling.

Power generation turbines – Maintain sealing under heat and stress.

Marine propulsion systems – Resist seawater corrosion and vibration.

Chemical plant pumps – Handle aggressive chemicals without early failure.

Wastewater systems – Prevent leakage in abrasive and corrosive fluids.

In each case, bagues d'étanchéité en carbure de tungstène reduce failures and increase operating hours.

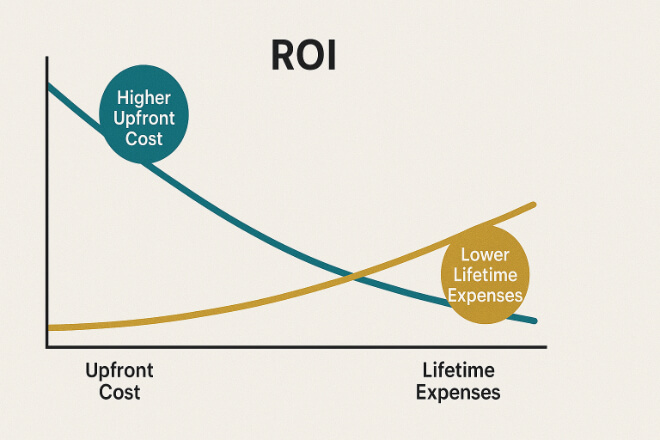

Coût vs valeur à long terme

Tungsten carbide seal rings have a higher initial price, but the long-term benefits include:

Lower downtime costs.

Moins de remplacements.

Extended equipment life.

Better overall ROI.

For decision-makers, this makes tungsten carbide a cost-effective investment.

Meilleures pratiques d'utilisation des bagues d'étanchéité en carbure de tungstène

Match grade to environment → Cobalt for shock, nickel for corrosion.

Assurer une installation correcte → Prevent scratches that weaken seals.

Lubricate correctly → Reduce friction and heat buildup.

Inspecter régulièrement → Detect early wear and prevent sudden failure.

These practices maximize uptime and extend seal life.

Sustainability Advantage

Tungsten carbide is recyclable. Worn seal rings can be collected and reprocessed into new products, reducing waste and supporting sustainability goals.

Points clés à retenir pour les décideurs

Tungsten carbide seal rings significantly reduce downtime in rotating equipment.

Leur durabilité, dureté, and corrosion resistance outperform alternatives.

Right binder choice ensures reliability in different industries.

Higher upfront cost delivers long-term savings.

Recycling enhances sustainability.

Conclusion

For rotating equipment in oil and gas, chemical, marine, and power industries, tungsten carbide seal rings are essential for reducing downtime.

Their ability to withstand harsh conditions ensures equipment runs longer, safer, and more efficiently.

For decision-makers, choosing tungsten carbide means fewer failures, lower costs, and stronger long-term value.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.