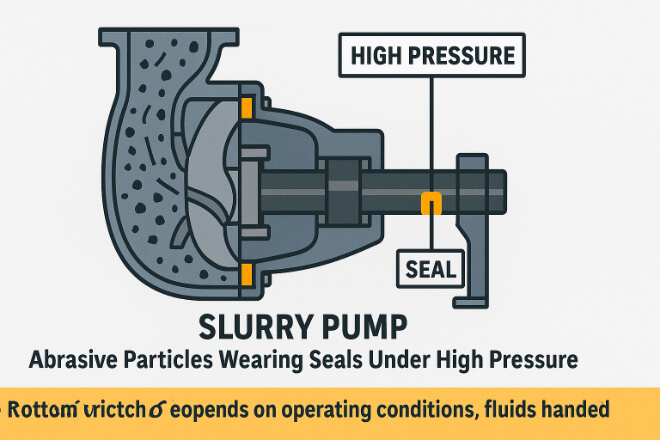

Slurry and abrasive fluids are some of the most challenging materials for industrial pumps, mixers, and turbines.

These fluids contain solid particles such as sand, silt, or minerals that can quickly damage equipment.

A reliable sealing system is essential to prevent leaks, reduce maintenance, and keep operations running smoothly.

Among the materials available, bagues d'étanchéité en carbure de tungstène are one of the best choices for slurry and abrasive fluid handling.

This article explains why, compares them to alternatives, and offers tips for decision-makers.

Challenges of Slurry and Abrasive Fluid Handling

Abrasive fluids create unique problems for seals and equipment:

Severe wear → Solid particles grind against seals, causing rapid damage.

High pressure → Slurry pumps often operate under extreme loads.

Variable flow → Uneven conditions can stress seals.

Corrosion → Many slurries include chemicals or seawater.

Coût des temps d'arrêt → Seal failure can stop production and cause expensive repairs.

These challenges require a material that can withstand heavy wear and stress.

Propriétés des bagues d'étanchéité en carbure de tungstène

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties make it ideal for abrasive environments:

Extrême dureté → Resists scratching and erosion from particles.

Haute résistance à la compression → Handles pressure without cracking.

Résistance à l'usure → Extends service life compared to steel or ceramic.

Résistance à la corrosion → Protects against chemical-rich slurries.

Stabilité thermique → Performs reliably under heat generated by friction.

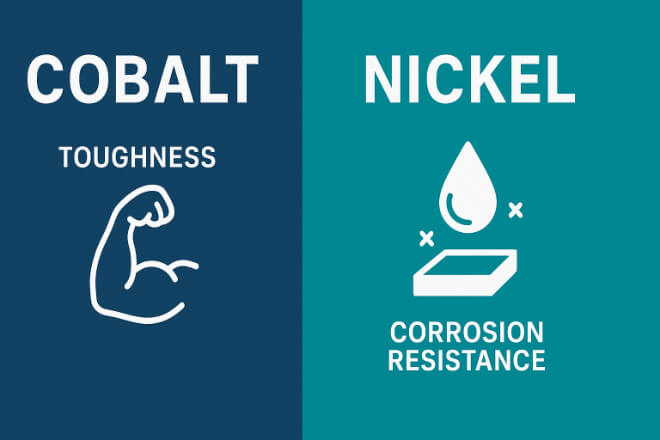

Carbure de tungstène lié au cobalt ou au nickel

Two main grades are used for slurry and abrasive fluids:

1). Carbure de tungstène lié au cobalt

Mieux dureté and shock resistance.

Best for mining, dredging, and oilfield slurry pumps.

2). Carbure de tungstène lié au nickel

Plus fort corrosion resistance.

Better for slurries with chemicals or seawater.

Selecting the right binder ensures maximum seal life in your application.

Avantages par rapport aux autres matériaux d'étanchéité

| Fonctionnalité | Carbure de tungstène | Céramique | Acier |

|---|---|---|---|

| Résistance à l'usure | Excellent pour les abrasifs | Moderate in slurry | Poor in abrasive fluids |

| Dureté | High; resists shock/vibration | Low; brittle under impact | Modéré |

| Résistance à la corrosion | Good; nickel-bonded excels | Excellent en chimie | Poor in slurry/chemicals |

| Durée de vie | Long-lasting under stress | Modéré | Short in harsh media |

| Coût | Higher upfront; better ROI | Coût initial inférieur | Lowest initial cost |

Applications in Slurry and Abrasive Fluid Systems

Les bagues d'étanchéité en carbure de tungstène sont largement utilisées dans :

Mining and dredging pumps – Handle mineral slurries with high abrasiveness.

Oilfield drilling systems – Manage abrasive drilling fluids under pressure.

Wastewater treatment – Resist wear in grit-filled fluids.

Marine and dredging operations – Provide durability in sandy seawater.

Chemical plants – Handle corrosive and abrasive mixtures safely.

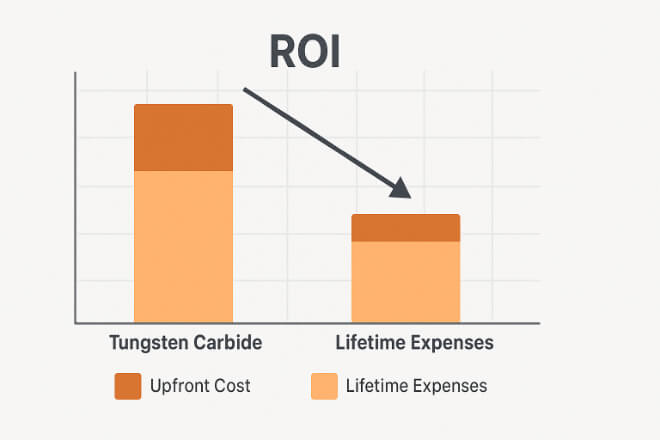

Coût vs valeur à long terme

While tungsten carbide seal rings cost more upfront, they:

Réduire les temps d'arrêt → Less frequent failures and replacements.

Des coûts de maintenance réduits → Fewer labor hours and spare parts.

Protéger l'équipement → Prevent expensive damage to pumps and shafts.

Améliorer le retour sur investissement → Longer service life offsets initial price.

Decision-makers in slurry handling benefit from lower life cycle cost over time.

Meilleures pratiques d'utilisation des bagues d'étanchéité en carbure de tungstène

To maximize performance in abrasive environments:

Choose the correct binder → Nickel for corrosive slurries, cobalt for impact loads.

Installer avec soin → Avoid scratches or misalignment that shorten life.

Utiliser une lubrification appropriée → Reduces heat and friction wear.

Inspecter régulièrement → Spot early wear to prevent failure.

Travailler avec des fournisseurs expérimentés → Ensure proper material and design for your system.

Avantages environnementaux

Tungsten carbide is recyclable. Worn rings can be collected and reprocessed into new products, reducing waste and supporting environmental sustainability—a growing priority for industries worldwide.

Points clés à retenir pour les décideurs

Tungsten carbide seal rings outperform steel and ceramic in abrasive, high-pressure environments.

The right binder (nickel or cobalt) ensures reliability under specific conditions.

Though costlier upfront, tungsten carbide reduces downtime and overall expenses.

Recyclability adds sustainability benefits.

Conclusion

Handling slurry and abrasive fluids requires seals that can survive extreme wear, pressure, and corrosion.

Tungsten carbide seal rings deliver the toughness and durability needed to keep pumps, compressors, and turbines operating safely and efficiently.

For decision-makers, choosing tungsten carbide is a strategic investment in uptime, performance, and sustainability.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.