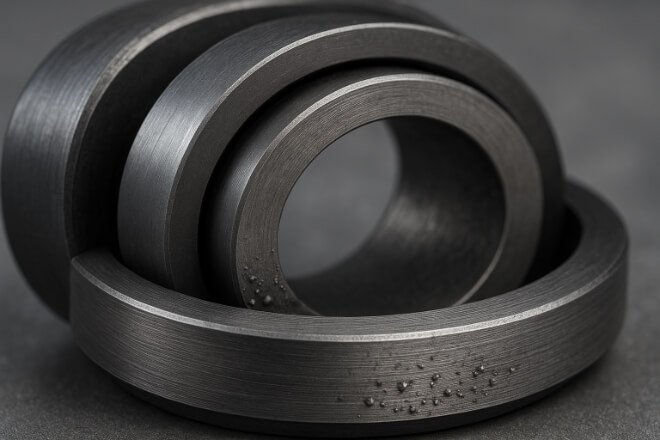

In the world of mechanical seals, tungsten carbide rings are trusted for their strength, dureté, et résistance à l'usure.

Yet even the toughest materials can fail when exposed to harsh conditions.

Three of the most common failure types in carbide rings are abrasion, edge chipping, and thermal shock.

Understanding these failure signatures helps maintenance teams and decision-makers prevent costly equipment downtime and premature replacement.

This article explains what each failure looks like, why it happens, and how to prevent it.

What Is Abrasion in Carbide Rings?

Abrasion occurs when hard particles or contaminants in the sealing fluid continuously scratch or cut the carbide surface. Over time, this friction wears down the smooth sealing face.

Typical signs include:

A dull, rough, or matte surface instead of a mirror finish

Grooves or scoring marks following the rotation direction

Reduced sealing efficiency due to uneven contact

For example, in slurry pumps handling sand or ceramic particles, abrasive wear is common.

Even with high-dureté carbide, continuous exposure to these solids gradually removes material.

1). Main Causes of Abrasion

Poor filtration or absence of a clean flush system

Use in high-solid-content liquids (slurry, mud, pulp)

Improper material pair — for instance, using carbide vs. carbide in dirty environments

2). How to Reduce Abrasion

To prevent abrasive wear, system designers often use:

Better filtration systems to remove solid particles

Harder grades of tungsten carbide (low cobalt content)

Proper seal flushing to keep faces clean

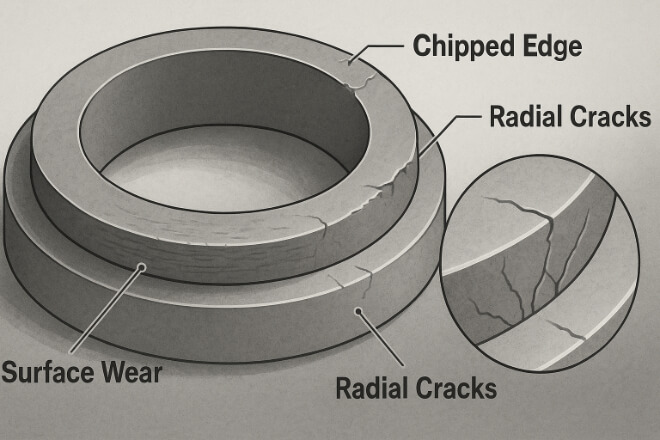

Edge Chipping in Carbide Seal Rings

Edge chipping is another common failure mode, especially during installation or sudden load changes.

Tungsten carbide is extremely hard, but also brittle — meaning sharp impacts can cause localized cracks or small chips along the seal edge.

Typical symptoms include:

Tiny chips along the outer or inner edge of the seal face

Leakage due to uneven sealing

Progressive cracking under cyclic stress

For example, if a seal is installed with uneven torque or dropped during handling, micro-chips can appear that later propagate during service.

1). Causes of Edge Chipping

Mishandling or dropping during assembly

Poor seal alignment or over-tightening

Contact between faces during dry running

Vibration or shaft misalignment

2). Prevention Methods

Train technicians on proper installation procedures

Use chamfered edge designs to distribute stress

Avoid dry starts — ensure lubricating film before operation

Check concentricity and alignment before startup

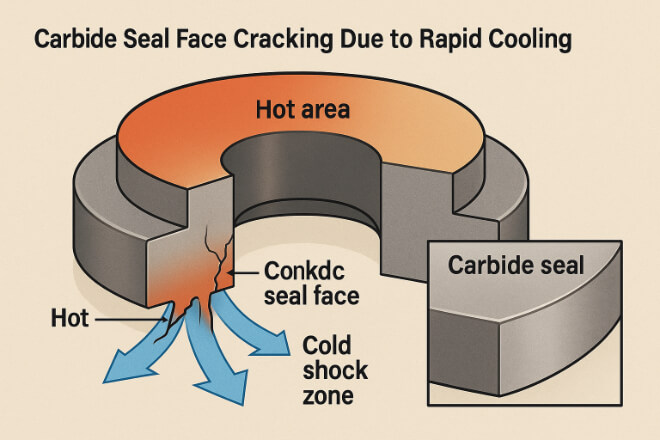

Thermal Shock in Tungsten Carbide Seals

Thermal shock happens when the seal face experiences a rapid temperature change — such as sudden cooling after a hot run.

The extreme difference in temperature between surface and interior creates internal stress, which can lead to cracks or even complete ring fracture.

1). Recognizable Symptoms

Network-like surface cracks (spider-web pattern)

Radial cracks running from the inner diameter to outer edge

Broken or split seal rings

In a real-world case, a pump operating in hot oil was suddenly flushed with cold water during maintenance.

The temperature drop was over 150°C — the tungsten carbide ring cracked immediately due to thermal stress.

2). Common Causes

Rapid cooling or heating during operation

Lack of cooling control or sudden flow change

Poor material selection for high-temperature fluids

3). Prevention Tips

Maintain steady temperature conditions

Avoid flushing with cold fluid after hot operation

Choose nickel-bonded tungsten carbide for better thermal resistance

Comparing the Three Failure Modes

Here’s a summary table to help you quickly distinguish between abrasion, edge chipping, and thermal shock based on their main visual and operational symptoms:

| Failure Type | Typical Symptoms | Main Cause | Preventive Actions |

|---|---|---|---|

| Abrasion | Dull surface, grooves, wear marks | Particles in fluid, poor flushing | Use clean flush, improve filtration |

| Écaillage des bords | Small chips on edges, leakage | Mishandling, dry running | Proper handling, alignment, lubrication |

| Thermal Shock | Cracks or complete ring fracture | Rapid temperature change | Gradual cooling, temperature control |

Practical Example: When Multiple Failures Overlap

In real conditions, seal rings often show a mix of these failure types. For instance, a seal that runs dry may first chip its edges.

Once the fluid returns, thermal stress adds micro-cracks, and abrasive particles worsen wear.

In one refinery case, a mechanical seal failed within 2 weeks due to:

Improper flushing system setup

Frequent temperature cycling

Slurry ingress from an upstream filter leak

This example highlights the importance of system-level design and not just material selection.

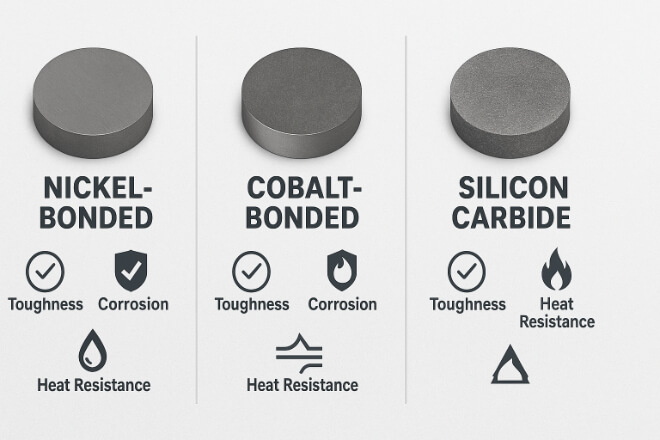

Choosing the Right Material and Design

For harsh or unpredictable conditions, choosing the right carbide composition is critical.

Decision-makers can improve seal reliability by considering:

Nickel-bonded carbides for résistance à la corrosion and thermal resistance

Cobalt-bonded carbides for higher dureté

Silicon carbide vs tungsten carbide pairing for cleaner sealing

Additionally, proper surface finish (Ra 0.02–0.04 µm) and flatness ensure better face contact, reducing local stress.

Maintenance and Inspection Recommendations

Routine inspection helps detect early-stage failures before they lead to full shutdowns.

A good inspection plan should include:

Visual checks for micro-chipping or dullness

Measurement of face flatness and surface roughness

Monitoring of temperature and flush flow rate

By identifying these early signs, companies can extend seal life and reduce unplanned maintenance costs.

Conclusion

Understanding abrasion, edge chipping, and thermal shock is essential for predicting and preventing carbide ring failure.

Each failure signature tells a story about what’s happening inside your system — from contamination and thermal imbalance to poor handling.

With better design, material selection, and maintenance habits, you can achieve longer seal life and fewer equipment stoppages — a key goal for any production manager or plant engineer.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.