Tungsten carbide has long been one of the most reliable materials for mechanical seal faces.

It combines dureté, résistance à l'usure, and dimensional stability — key properties for long service life in pumps, compressors, and mixers.

However, even the strongest materials wear over time. When a tungsten carbide face becomes scratched, warped, or worn, plant engineers often face a difficult question: should we re-lap and reuse it, or replace it entirely?

This article discusses how re-lapping works, when it is cost-effective, and what technical factors decision-makers should consider before approving re-use.

What Is Re-Lapping of Tungsten Carbide Faces?

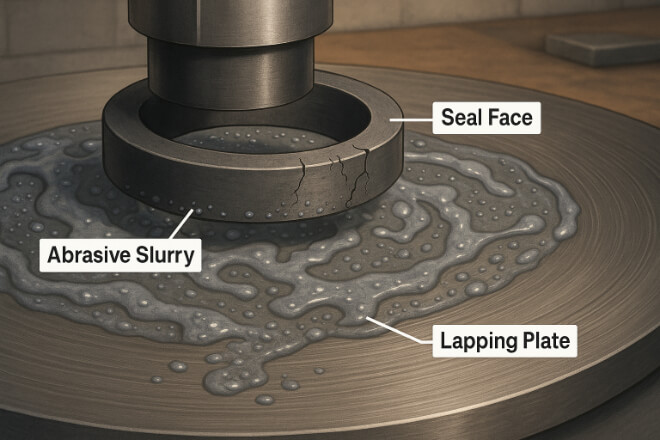

Re-lapping is the process of restoring the flatness and surface finish of a used tungsten carbide face by removing a thin layer of material.

It is done on precision lapping machines using fine abrasives to bring the surface back to its original sealing condition.

The goal of re-lapping is to:

Restore surface smoothness (Ra 0.02–0.05 µm)

Correct minor warping or distortion

Recreate the necessary flatness for proper sealing

Extend the life of the seal face without full replacement

For example, a mechanical seal face from a chemical pump may only have shallow scratches and minor wear.

Instead of scrapping it, the part can be re-lapped and returned to service at a fraction of the cost.

Why Re-Lapping Can Be Cost-Effective

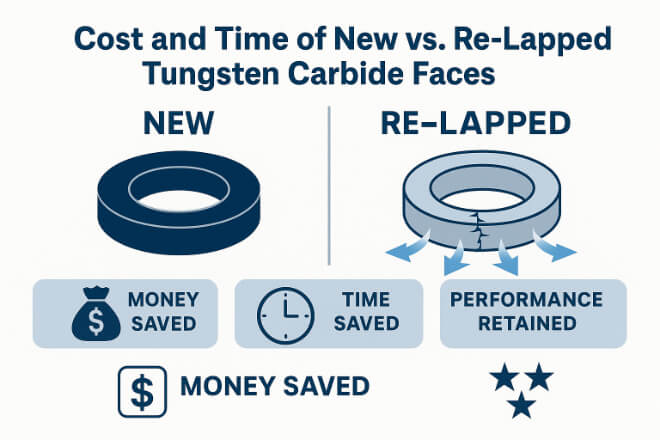

The economic logic behind re-lapping is simple — tungsten carbide parts are expensive.

The raw material, pressing, sintering, and grinding all contribute to high replacement costs. In comparison, re-lapping usually costs only 20–40% of a new part.

When done properly, a re-lapped face can perform nearly as well as a new one, making it a practical maintenance choice for companies seeking to reduce operational costs.

Below is a general cost comparison:

| Item | New Seal Face | Re-Lapped Seal Face | Material & Production Cost | 100% | 30–40% | Delivery Time | 4–6 weeks | 3–5 days | Surface Quality (Ra) | 0.02–0.04 µm | 0.02–0.05 µm | Service Life (Typical) | 100% | 80–90% |

|---|

For high-volume or critical sealing operations — such as refineries, chemical plants, and power stations — these savings quickly add up.

When Re-Lapping Is a Good Option

Re-lapping is not always suitable, but in many cases, it is a smart and reliable solution.

Here are the main conditions where it makes sense:

1). The Face Has Minor Wear Only

If the face has light scratches or dullness but no deep cracks or major distortion, it can be re-lapped easily.

Minor flatness deviations (under 5 µm) can usually be corrected.

2). The Substrate Integrity Is Intact

If there are no fractures, edge chipping, or binder leaching issues, the carbide structure remains stable enough for reuse.

3). The Surface Coating Is Restorable

For coated faces (like DLC or TiN), re-lapping can be followed by re-coating. This gives a refreshed sealing surface with the same chemical resistance.

4). When Quick Turnaround Is Needed

In remote sites or urgent shutdowns, re-lapping can restore components within days, avoiding long lead times for new parts.

When Re-Lapping Is Not Recommended

There are situations where re-lapping may actually waste time and money.

Below are the main red flags:

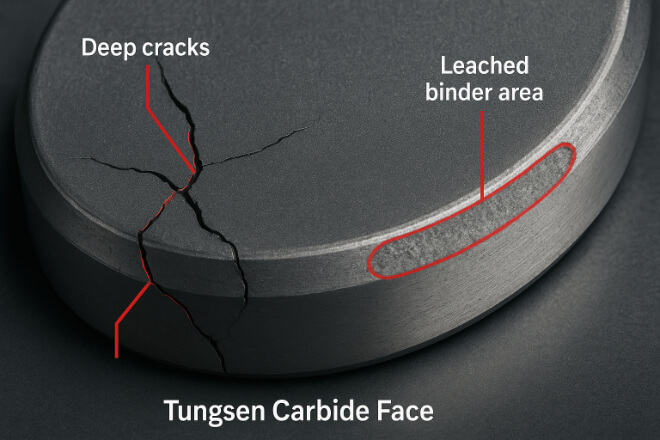

1). Deep Cracks or Fractures

Once a carbide face has internal cracks, lapping cannot fix it. The integrity is lost, and it may fail again under stress.

2). Severe Erosion or Leaching

If corrosion or binder leaching has created pores or weakened areas, re-lapping will not restore mechanical strength.

3). Edge Chipping Beyond Repair

Small chips can sometimes be smoothed out, but large or structural edge damage makes the face unsuitable for reuse.

4). Thickness Below Minimum

Each lapping process removes material. If the face becomes thinner than design limits, sealing pressure and stiffness are reduced.

The Re-Lapping Process Explained

The process involves several controlled steps to restore surface quality:

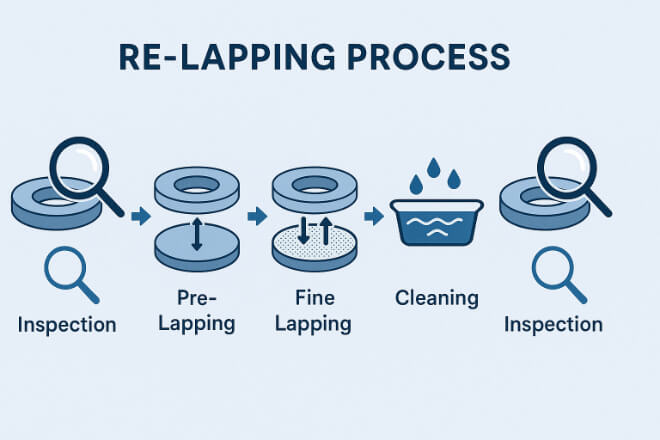

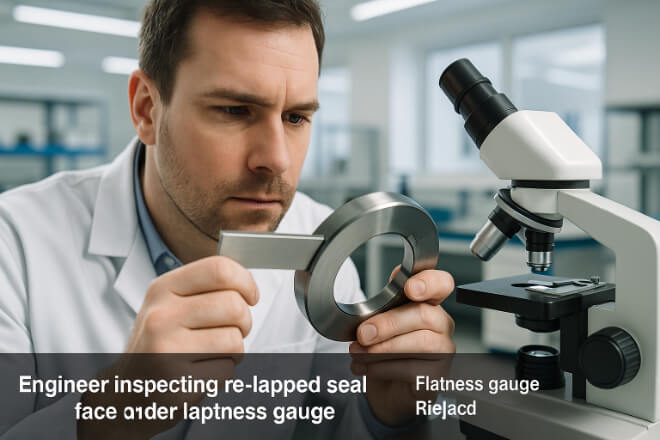

Initial Inspection – The face is cleaned and checked for cracks, warping, or deep scratches using optical flat testing.

Pre-Lapping – Coarser abrasives are used to remove surface damage and re-establish flatness.

Fine Lapping – Fine diamond slurry is applied to achieve the required mirror finish.

Cleaning and Drying – Ultrasonic cleaning removes all abrasive residues.

Final Inspection – Flatness, surface finish, and dimensional tolerances are verified.

A well-managed workshop can deliver consistent results comparable to OEM quality.

Quality Control and Verification

After re-lapping, proper quality checks ensure the face will perform reliably.

Critical inspection parameters include:

Flatness: Typically within 1–2 light bands (≈0.6–1.2 µm)

Surface Roughness (Ra): 0.02–0.05 µm

Visual Defect Check: No pits, scratches, or cracks

Thickness Measurement: Within manufacturer tolerance

Only components that meet all standards should be approved for reuse.

Some plants keep a traceability record for each re-lapped part to track life cycles.

Exemple concret

A large petrochemical plant in Southeast Asia faced frequent mechanical seal replacements due to slurry contamination.

Each tungsten carbide face cost over $800, and replacements took 6 weeks.

By introducing a local re-lapping and reuse program, the plant:

Reduced seal replacement costs by 50%

Cut delivery time from 6 weeks to 4 days

Extended service intervals by 40% through controlled re-lapping cycles

This example shows that with proper inspection and documentation, re-lapping is both technically and economically beneficial.

Evaluating Cost-Effectiveness

To decide whether re-lapping is cost-effective, consider the following:

Part Cost vs. Re-Lap Cost – If re-lapping costs less than 40% of a new part, it’s generally worthwhile.

Remaining Thickness – If more than 90% of the original thickness remains, reuse is feasible.

Operating Conditions – Stable and clean fluids favor re-use; harsh or corrosive media may justify replacement.

Performance History – If a re-lapped face performs nearly as long as a new one, re-use adds real value.

Below is a simplified decision table:

| Condition | Re-Lap? | Minor scratches, no cracks | Oui | Light wear, no distortion | Oui | Edge chipping or cracks | No | Corrosion or leaching signs | No | Urgent turnaround needed | Oui |

|---|

Conclusion

Re-lapping and re-use of tungsten carbide seal faces can be a smart cost-saving practice — but only when done under controlled inspection and process standards.

For decision-makers, the key question is not “Can we re-lap?” but “Should we re-lap under these specific conditions?”

When properly applied, re-lapping extends component life, reduces waste, and ensures reliable seal performance — making it a valuable part of any maintenance strategy.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.