Producing a carbide seal ring that can survive high pressure, abrasive fluids, and corrosive chemicals is not just about material hardness—it’s about precision at every stage of manufacturing.

From the casting of poudre de carbure de tungstène to the final mirror-polished surface, each step determines how well the ring seals, resists wear, and maintains flatness in service.

This article explains the complete workflow of how carbide seal rings are made—from powder to perfection—highlighting the importance of process control, surface quality.

And inspection standards that decision-makers in pump and compressor industries must understand.

Powder Preparation: The Foundation of Quality

The journey begins with selecting tungsten carbide (WC) powder and a suitable binder metal, usually cobalt (Co) or nickel (Ni).

The purity and particle size of these powders directly affect the final strength and microstructure of the seal ring.

1). Key Steps

Raw material selection: WC powder with particle size between 0.5–1.5 µm.

Binder mixing: Typically 6–12% cobalt or nickel added for dureté.

Homogenization: Blending in ball mills ensures even distribution.

Drying and sieving: To remove moisture and achieve uniform particle flow.

2). Why It Matters

Uniform powder mixing prevents weak zones and ensures consistent density after sintering—critical for rings that must maintain tight tolerances under stress.

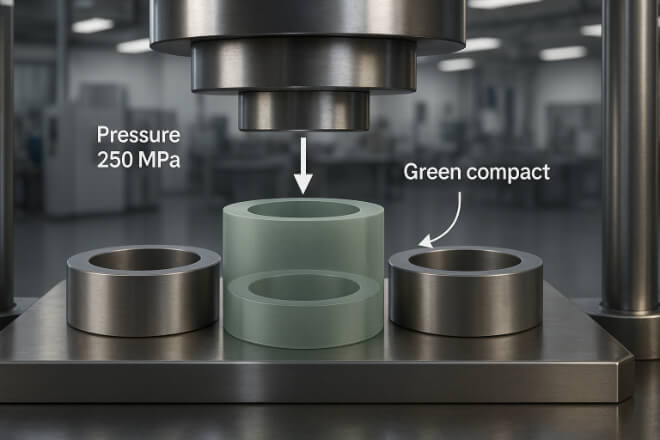

Pressing and Preforming: Shaping the Green Body

Once the powder is prepared, it is pressed into a ring-shaped compact using CNC-controlled dies or cold isostatic presses (CIP).

1). Typical Conditions

Pressing pressure: 150–300 MPa.

Shrinkage allowance: 18–22% volume loss expected after sintering.

Binder uniformity: Ensures even shrinkage to avoid cracking.

The compact, often called a “green body,” has the basic shape but is still fragile and porous.

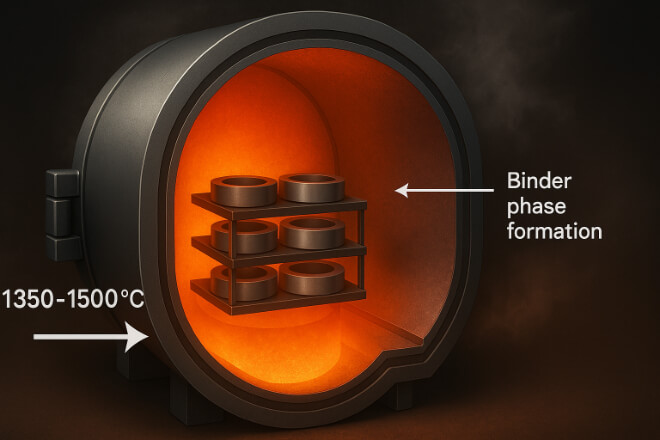

Sintering: Turning Powder into Solid Metal

Sintering is the most critical stage in carbide manufacturing. The green body is heated in a vacuum or hydrogen furnace to 1350–1500°C.

1). What Happens During Sintering

WC particles fuse together, eliminating voids.

Binder metal melts and forms a continuous phase.

Final density reaches >99% of theoretical density.

This transforms the weak green ring into a hard, dense carbide blank with compressive strength exceeding 4000 MPa.

Rough Machining: Establishing Geometry

After sintering, the carbide blank is extremely hard, so diamond tools or CNC grinding machines are used to achieve preliminary dimensions.

1). Common Processes

Outer diameter grinding

Inner bore sizing

Thickness calibration

At this stage, tolerances are moderate, typically within ±0.05 mm, leaving stock for fine lapping later.

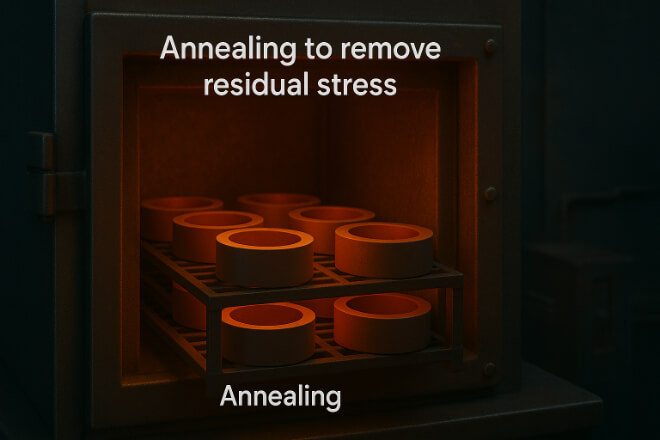

Stress Relief and Quality Heat Treatment

Before final finishing, the rings undergo stress-relief annealing to remove any residual stresses caused by grinding.

This step helps prevent distortion or cracking during the lapping and polishing stages, which require precise flatness control.

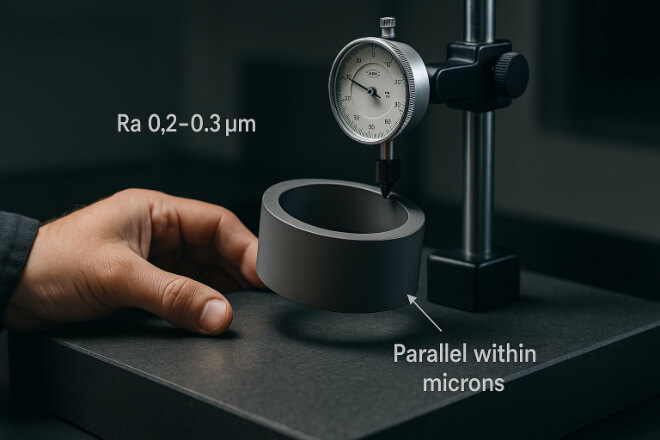

Fine Grinding: Preparing for Flatness

Fine grinding removes minor surface defects and prepares the faces for lapping.

Special resin-bonded diamond wheels are used to achieve surface roughness around Ra 0.2–0.3 µm.

Fine grinding ensures the ring faces are flat and parallel within microns—setting the stage for the mirror polish finish.

Lapping and Polishing: Achieving the Mirror Finish

Lapping is where carbide seals achieve their functional excellence. It defines the seal face flatness, smoothness, and sealing performance.

1). Typical Workflow

| Step | Abrasive Material | Target Roughness (Ra) | But |

|---|---|---|---|

| Rough Lapping | Diamond slurry (15–30 µm) | 0.3–0.4 µm | Remove grinding marks |

| Intermediate Lapping | Diamond slurry (6–9 µm) | 0.1–0.2 µm | Flatten surface and remove micro-scratches |

| Final Polishing | Colloidal diamond (1 µm or less) | 0.04–0.05 µm | Achieve mirror-level finish |

After polishing, the surface reflects light like a mirror and achieves leak-free sealing when paired with another flat face.

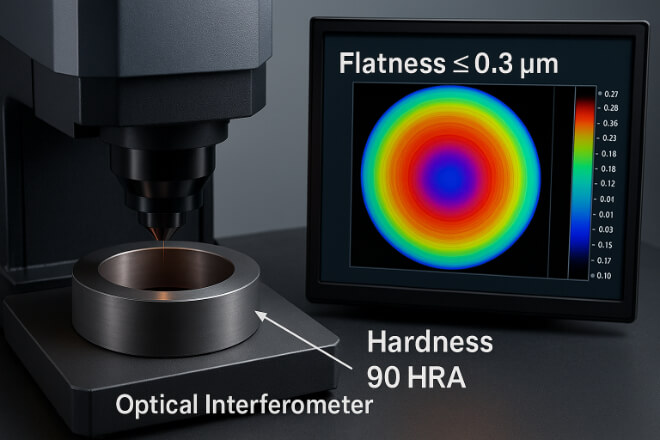

Inspection and Quality Control

Quality inspection ensures each ring meets both mechanical and geometric standards.

1). Key Measurements

Flatness: ≤ 0.3 µm

Surface roughness: ≤ 0.05 µm

Parallelism: ≤ 0.002 mm

Dureté: 85–90 HRA

Non-destructive testing methods like ultrasonic inspection detect internal voids, while optical interferometers verify surface profile.

Cleaning and Packaging for Cleanroom Use

Because carbide seal rings are used in industries like semiconductors, pumps, and chemical processing, final cleaning is crucial.

Steps

Ultrasonic cleaning in deionized water or isopropanol.

Drying in filtered air.

Packaging in anti-static, vacuum-sealed bags to prevent dust contamination.

Clean packaging ensures that rings are ready for direct installation into sensitive equipment.

Process Flow Overview

| Étape du processus | Key Operation | Main Objective |

|---|---|---|

| Préparation de la poudre | Mix WC powder with binder | Ensure uniform material composition |

| Pressage | Form green compact | Define basic geometry |

| Frittage | Vacuum furnace heating | Achieve full density and strength |

| Rough & Fine Grinding | Diamond grinding | Reach precise dimensions |

| Lapping & Polishing | Mirror-level finishing | Perfect sealing surface |

| Inspection & Cleaning | Metrology & ultrasonic cleaning | Ensure quality and cleanliness |

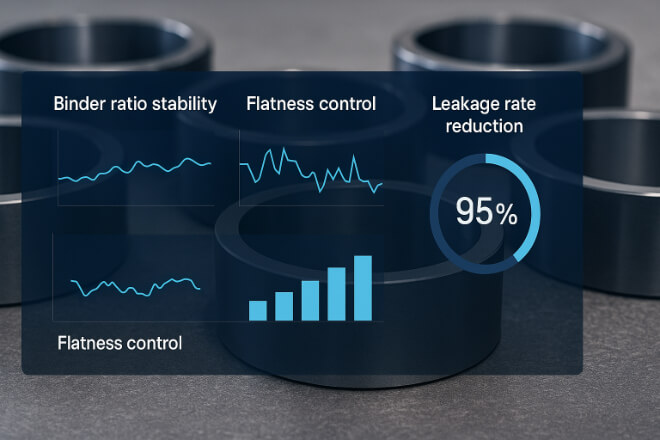

Why Process Control Matters for End Users

For pump, compressor, and semiconductor equipment manufacturers, understanding the production process helps in specifying quality standards.

Even small variations in grain size, binder ratio, or lapping pressure can impact:

Seal flatness and leakage rate.

Resistance to thermal cracking.

Compatibility with corrosive fluids.

Reliable suppliers with end-to-end quality control reduce failure risks and ensure consistent performance across batches.

Conclusion

From raw powder preparation to mirror-level polishing, every step in the carbide seal ring manufacturing process influences product performance.

By maintaining strict control over each stage—composition, sintering, grinding, polishing, and inspection—manufacturers deliver seals that meet global standards for precision, reliability, and cleanliness.

For decision-makers, understanding this workflow helps select vendors who can truly guarantee leak-free, long-life carbide seal rings for critical industrial applications.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.