In high-pressure machinery such as pumps, compressors, and hydraulic systems, every part must withstand extreme stress, friction, and temperature.

Among all wear-resistant components, bagues en carbure de tungstène stand out as one of the most reliable materials for these demanding environments.

The key lies in the science of strength. Tungsten carbide combines dureté, compressive strength, and thermal stability that allow it to perform where other materials fail.

This article explains why tungsten carbide is ideal for high-pressure bushings, examining its structure, performance characteristics, and practical industrial benefits.

What Are High-Pressure Bushings?

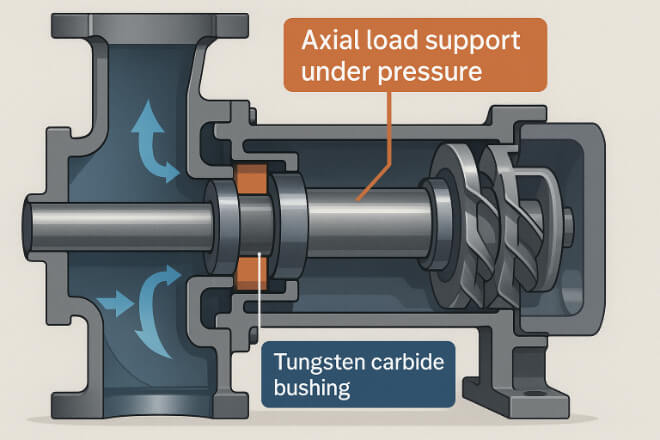

Bushings act as bearings or sleeves that support rotating shafts and reduce friction. In high-pressure systems, they must also resist:

Axial and radial loads

Continuous vibration

Dilatation thermique

Fluid pressure and cavitation

A high-pressure bushing must therefore provide both structural strength and precise dimensional control — maintaining alignment even under thousands of pounds per square inch of stress.

The Mechanical Strength of Tungsten Carbide

| Propriété | Valeur typique | Effect on Performance |

|---|---|---|

| Dureté | 88–92 HRA | Prevents surface deformation and wear |

| Résistance à la compression | 4,000–6,000 MPa | Handles high axial and radial loads |

| Elastic Modulus | 500–700 GPa | Minimizes deflection under stress |

These properties explain why bagues en carbure de tungstène maintain perfect shape and alignment even under extreme hydraulic or mechanical pressure.

Where steel or bronze bushings deform, tungsten carbide stays stable.

Why Hardness Matters in Pressure Applications

Hardness is not just a number — it’s the foundation of performance.

In high-pressure pumps, the shaft constantly rotates against the bushing, and any softness would lead to wear, leaks, or imbalance.

Tungsten carbide’s extreme hardness ensures:

Minimal clearance loss

Stable lubrication film

Resistance to micro-abrasion

Even after thousands of hours in continuous duty, carbide bushings retain their original surface geometry.

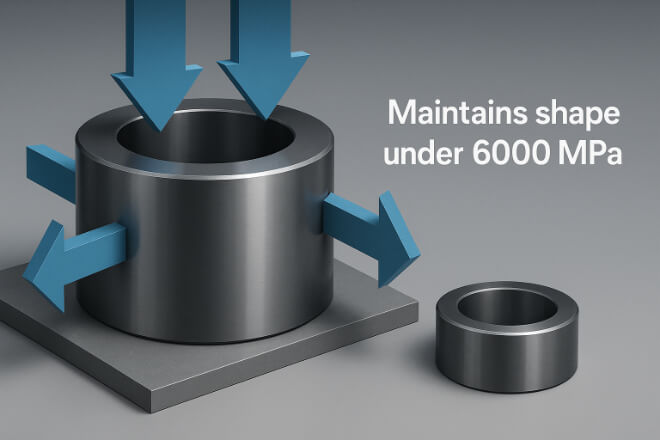

Compressive Strength and Structural Integrity

Tungsten carbide’s compressive strength is among the highest of any engineering material.

It can withstand more than 4000 MPa before deformation — that’s roughly ten times stronger than most steels.

This strength allows bushings to:

Support heavy shaft loads

Operate in high-pressure pumps and reactors

Prevent microcracking during start-stop cycles

In oilfield or chemical pumps, where pressure surges are common, carbide bushings maintain shape and alignment, preventing shaft wobble and seal failure.

The Role of the Binder Metal

| Type de liant | Avantages | Best Use Case |

|---|---|---|

| Cobalt (Co) | High toughness and fatigue strength | Oil, gas, and power plant pumps |

| Nickel (Ni) | Superior corrosion resistance | Chemical and seawater environments |

The binder phase holds tungsten carbide grains together.

A cobalt-bonded carbide offers high impact resistance, while a nickel-bonded version provides stability in corrosive or high-moisture conditions.

For high-pressure bushings, this balance of dureté and ductility prevents catastrophic cracking when pressure spikes occur.

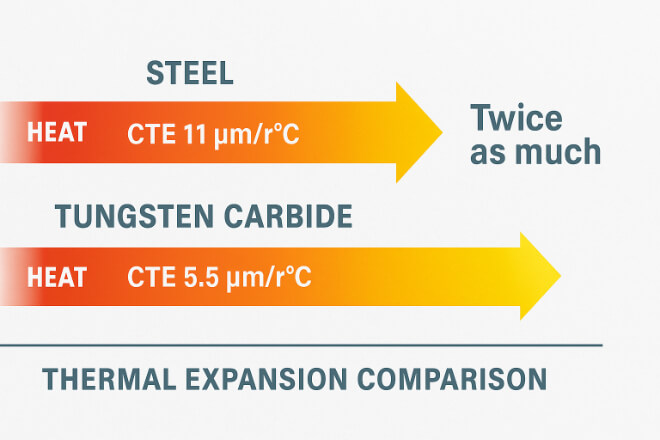

Dimensional Stability Under Heat and Stress

Tungsten carbide expands very little under heat — with a thermal expansion coefficient about half that of steel.

This property keeps shaft clearances constant even when equipment heats up during long operation.

Les principaux avantages comprennent :

Better shaft alignment

Stable clearances under variable temperatures

Reduced risk of thermal distortion

These factors make tungsten carbide bushings critical in boiler feed pumps, compressors, and turbines, where continuous thermal cycles occur.

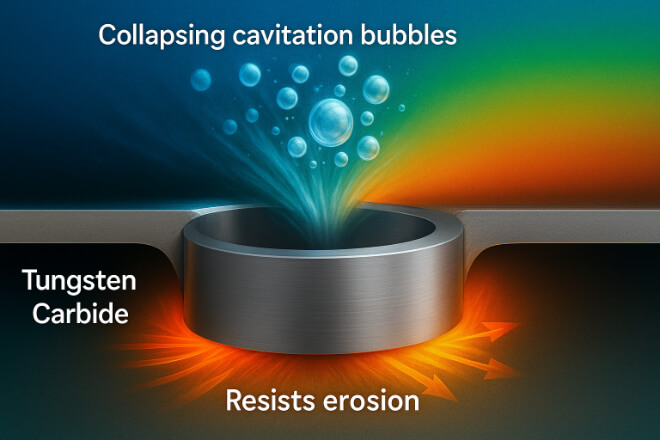

Resistance to Corrosion and Cavitation

In high-pressure systems, fluid speed and turbulence can cause cavitation — tiny vapor bubbles that collapse and damage surfaces.

Tungsten carbide resists both chemical attack and erosive pitting, especially when nickel binders are used.

This protection ensures that bushings maintain sealing performance in challenging fluids such as:

Hot water

Hydrocarbons

Sea or brine water

Fluides de procédé acides ou alcalins

Comparaison avec d'autres matériaux

| Matériel | Dureté (HRA) | Compressive Strength (MPa) | Résistance à la corrosion |

|---|---|---|---|

| Bronze | 60 | 500 | Modéré |

| Acier trempé | 75 | 1,500 | Faible à moyen |

| Carbure de tungstène | 90 | 4,500 | Excellent |

This table clearly shows that tungsten carbide dominates in all key mechanical categories, making it the superior choice for high-pressure service.

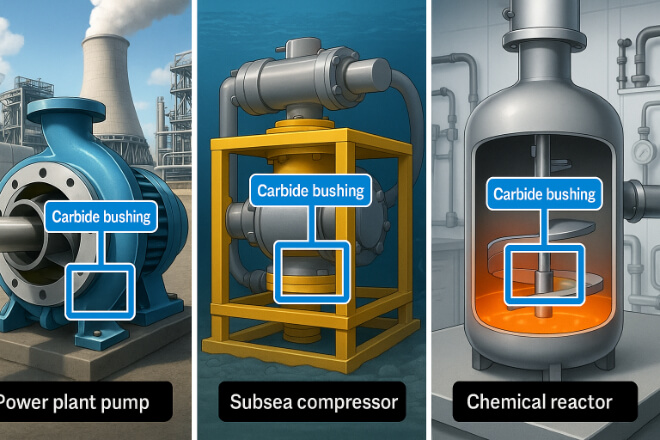

Exemples de l'industrie

Power plants: Boiler feed pumps rely on carbide bushings for continuous pressure cycles.

Pétrole et gaz: Subsurface pumps and gas compressors use carbide bushings to avoid galling and corrosion.

Chemical processing: High-pressure acid and slurry handling systems depend on nickel-bonded carbide sleeves.

In all these cases, tungsten carbide bushings reduce downtime, extend service intervals, and improve machine reliability.

Conclusion

The ability of tungsten carbide bushings to perform under high pressure is no coincidence.

It comes from a combination of hardness, compressive strength, corrosion resistance, and thermal stability.

These properties ensure that bushings maintain shape, alignment, and sealing integrity even in the most punishing industrial environments.

For decision-makers, choosing tungsten carbide is not just about material strength — it’s about long-term reliability, lower maintenance costs, and superior operational safety.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.