bagues en carbure de tungstène are known for their durability, résistance à l'usure, and high performance in harsh environments. However, even the best-quality bushings can fail, leading to equipment downtime, costly repairs, and lost productivity.

Calculating the total cost of downtime due to failed bushings and measuring the return on investment (ROI) of high-quality tungsten carbide bushings is essential for companies aiming to make informed decisions.

In this blog, we’ll explore how to calculate the total cost of downtime, the role of tungsten carbide bushings in reducing this cost, and how to determine ROI for your bushing investments.

The Importance of Downtime Costs in Manufacturing

In any manufacturing or industrial operation, downtime can be extremely costly.

Whether caused by machinery failure, equipment breakdowns, or the need for repairs, unplanned downtime disrupts production schedules and affects overall efficiency. Here’s why downtime costs matter:

1). Loss of Productivity

When equipment is down, workers are often idle or forced to work on other tasks, leading to a direct loss of productivity.

For example, if a critical machine part, like a tungsten carbide bushing, fails, the entire production line may halt until a replacement is made or repairs are performed.

2). Increased Maintenance Costs

Downtime often requires quick fixes or emergency maintenance, which can be more expensive than planned repairs. Additionally, frequent downtime due to part failures can lead to higher maintenance costs over time.

3). Revenue Loss

Unplanned downtime directly impacts the revenue of a company. For every hour that production stops, the company loses potential output, which leads to reduced sales and delayed orders.

4). Damaged Reputation

Long or frequent downtimes can damage a company’s reputation, especially if they lead to delayed deliveries or product defects. This can affect customer trust and loyalty, potentially resulting in lost future business.

How to Calculate the Total Cost of Downtime

Calculating the total cost of downtime requires considering both direct and indirect costs. Here’s how to break down these costs:

1). Direct Costs

Labor Costs: If production workers are unable to work during downtime, calculate their wages during this period.

Lost Production: Multiply the production output per hour by the number of hours the equipment is down.

Repair Costs: Include the cost of repairing or replacing the failed parts, such as the tungsten carbide bushing.

2). Indirect Costs

Opportunity Costs: These are the potential revenue lost due to the delay in production. Calculate how much revenue could have been generated during the downtime.

Customer Satisfaction: Delays and missed deadlines can lead to customer dissatisfaction, which may result in lost orders or the need for discounts to keep customers.

Reputation Damage: Long-term damage to the company’s reputation can lead to reduced market share and lower sales over time.

Role of Tungsten Carbide Bushings in Minimizing Downtime

Tungsten carbide bushings play a crucial role in reducing downtime. Here’s how:

1). Durability and Longevity

Tungsten carbide bushings are known for their exceptional résistance à l'usure and long lifespan. This helps reduce the frequency of part failures and the need for frequent replacements.

The longer a bushing lasts, the less often machinery is taken offline for maintenance or replacement.

2). High Performance in Harsh Conditions

Tungsten carbide bushings can withstand high temperatures, corrosion, and abrasive conditions.

This makes them ideal for use in demanding industries such as exploitation minière, energy, and heavy machinery, where downtime is costly.

3). Reduced Maintenance Requirements

Because tungsten carbide bushings last longer and perform better, they reduce the need for regular maintenance. Fewer maintenance events mean less downtime and lower overall costs.

Calculating ROI for Tungsten Carbide Bushings

When investing in bagues en carbure de tungstène, it’s important to calculate the return on investment (ROI) to determine whether the cost is justified by the benefits. Here’s how you can calculate ROI for tungsten carbide bushings:

1). Calculate the Initial Investment

This includes the cost of purchasing the tungsten carbide bushings, installation, and any associated labor or machinery setup costs.

2). Estimate the Savings from Reduced Downtime

Estimate how much downtime will be reduced by using tungsten carbide bushings compared to traditional bushings. Multiply the saved downtime hours by the hourly cost of downtime.

3). Calculate the Total Cost of Ownership (TCO)

The total cost of ownership includes both the initial investment and the ongoing maintenance or replacement costs.

With tungsten carbide bushings, the TCO should be lower due to their durability and lower maintenance needs.

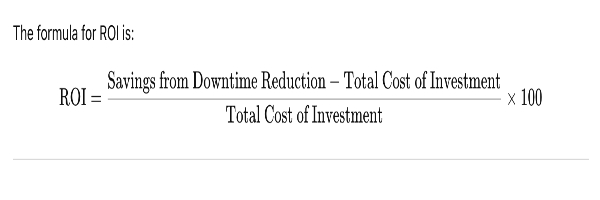

4). Calculate ROI

Conclusion

Understanding the total cost of downtime and calculating the ROI of tungsten carbide bushings is crucial for making informed decisions in industries where reliability and performance are paramount.

By investing in high-quality bushings, companies can reduce downtime, improve productivity, and save on repair and maintenance costs.

With proper calculation and strategic planning, businesses can ensure that their bushing investments contribute to long-term success and cost savings.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.