bagues en carbure de tungstène are essential components used in demanding industrial applications, including pumps, valves, and machinery.

One of the key factors determining the performance of these bushings is their density, which directly affects their dureté, résistance à l'usure, and overall durability.

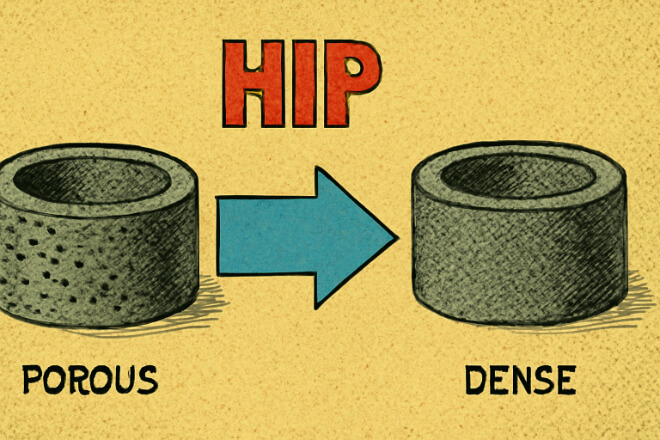

Hot Isostatic Pressing (HIP) is a critical process used to improve the density of tungsten carbide bushings.

This blog explores how HIP works, how it affects the densité of tungsten carbide bushings, and why this process is crucial for enhancing the performance of industrial components.

What is Hot Isostatic Pressing (HIP)?

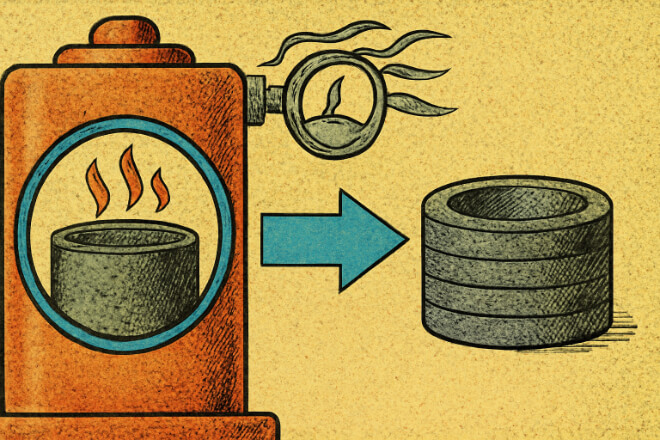

Hot Isostatic Pressing (HIP) is a manufacturing process that involves applying high temperature and pressure to materials, typically in a gas-filled chamber, to eliminate internal pores, improve material densité, and achieve uniformity in the material structure.

This process is particularly valuable for materials like tungsten carbide, which is commonly used in bushings due to its dureté et wear resistance.

How HIP Works

Pressure and Heat: In HIP, poudre de carbure de tungstène is placed in a sealed chamber and subjected to both high temperature and isostatic (uniform) pressure.

Elimination of Porosity: The heat and pressure cause the particles to fuse more effectively, closing any pores that might weaken the material.

Uniformity: This process ensures that the material has a uniform density, eliminating inconsistencies that could affect performance.

Importance of Density in Tungsten Carbide Bushings

The density of tungsten carbide bushings plays a crucial role in their performance, especially in demanding applications like pumps and heavy machinery.

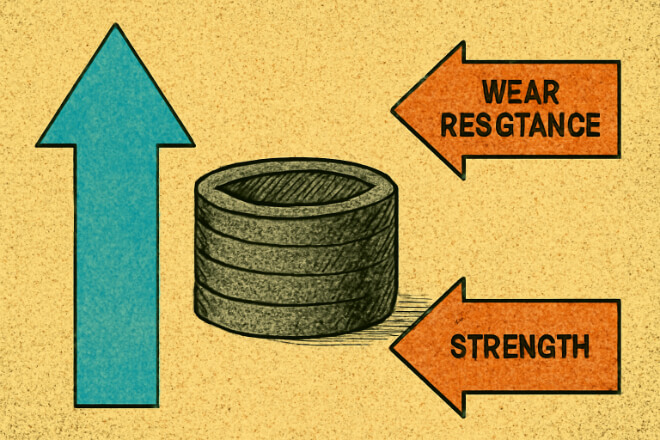

Higher density translates to better mechanical properties, which directly affect the bushing’s ability to withstand harsh conditions.

1). Impact of Densité on Performance

Dureté: Denser tungsten carbide bushings are harder, which improves wear resistance and prolongs service life.

Strength: Higher density materials are stronger and less prone to failure under high loads.

Impact Resistance: With improved density, tungsten carbide bushings are more resistant to impact, which is particularly important in high-pressure and abrasive environments.

2). Effect on Résistance à l'usure

The improved density achieved through HIP results in better wear resistance.

This is critical for applications where the bushing is subject to continuous friction, such as in pumps and compressors.

The denser the material, the better it resists the abrasive forces that can degrade its surface over time.

How HIP Improves the Density of Tungsten Carbide Bushings

HIP is specifically designed to increase the density of materials, making it an ideal process for tungsten carbide bushings.

By subjecting the material to both heat and pressure, HIP causes the tungsten carbide particles to bond more tightly, reducing porosity and increasing overall densité.

1). Reduction of Pores and Voids

One of the main benefits of HIP is the reduction of pores and voids within the material.

These internal imperfections can weaken the material and reduce its overall performance. By eliminating them, HIP ensures a more uniform and stronger bushing.

2). Achieving Consistent Material Properties

The uniformity achieved during the HIP process ensures that the tungsten carbide bushing has consistent material properties throughout its structure.

This is essential for reliable and predictable performance, particularly in high-stress applications where failure due to material inconsistencies could be catastrophic.

3). Enhancing Sintering Efficiency

HIP is often used in conjunction with the sintering process to improve the final density and properties of the tungsten carbide bushing.

Sintering involves heating the poudre de carbure de tungstène to just below its melting point to fuse the particles together.

HIP enhances this process by ensuring that the particles are evenly fused, leading to better density and material properties.

Advantages of Using HIP for Tungsten Carbide Bushings

HIP offers several advantages when it comes to manufacturing high-performance tungsten carbide bushings.

These benefits make it a preferred process for industries requiring high-quality bushings with enhanced mechanical properties.

1). Improved Durability and Longevity

By increasing the density of the tungsten carbide bushing, HIP ensures that the bushing can withstand extreme operating conditions, including high pressure, temperature fluctuations, and abrasive forces.

This significantly extends the lifespan of the bushing, reducing the frequency of replacements and maintenance.

2). Enhanced Performance in Harsh Environments

Tungsten carbide bushings treated with HIP can perform better in challenging environments, such as those found in exploitation minière, energy, and chemical processing industries.

The improved densité and strength allow the bushings to maintain their integrity even under extreme conditions.

3). Cost-Effective Manufacturing

While the HIP process can be more expensive than traditional methods, the long-term benefits—such as reduced wear and fewer replacements—make it a cost-effective solution.

The durability of HIP-treated bushings leads to lower operating costs over time, making them a wise investment for industries where performance is critical.

Applications of HIP-Processed Tungsten Carbide Bushings

Tungsten carbide bushings treated with HIP are used across various industries due to their superior properties. Here are some of the most common applications:

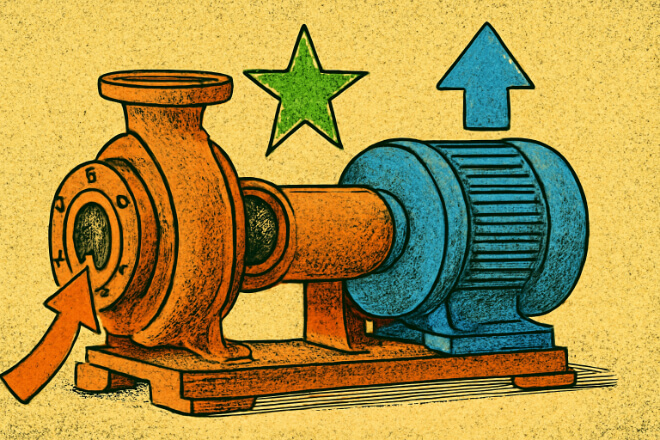

1). Pump and Compressor Systems

In pumps and compressors, tungsten carbide bushings are used to reduce friction and wear between moving parts.

HIP-treated bushings are ideal for these applications, as they provide superior résistance à l'usure and can withstand the high pressures and temperatures commonly encountered in these systems.

2). Oil and Gas Industry

Le pétrole et gaz industry often requires equipment that can withstand extreme conditions, including abrasive environments and high-pressure systems.

Tungsten carbide bushings treated with HIP provide the strength and durability needed for long-term performance in these environments.

3). Mining and Heavy Machinery

Mining operations and heavy machinery use tungsten carbide bushings to reduce wear in equipment subjected to abrasive forces.

HIP increases the wear resistance of the bushings, ensuring that they perform optimally even under harsh conditions.

Conclusion

Hot Isostatic Pressing (HIP) plays a key role in enhancing the density and performance of tungsten carbide bushings.

By improving material uniformity and reducing porosity, HIP ensures better durability, wear resistance, and strength, making it an ideal solution for industries like mining, oil and gas, and heavy machinery.

Despite higher initial costs, HIP-treated bushings offer long-term benefits, providing reliability and reducing downtime in critical applications.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.