Tungsten carbide tips are known for their outstanding performance in extreme conditions such as high pressure, high temperatures, and abrasive environments.

Dans des industries comme pétrole et gaz, exploitation minière, and manufacturing, these tips are essential for maintaining precision and durability under stress.

This blog will explore how tungsten carbide tips perform under extreme conditions and why they are the preferred choice for businesses facing challenging environments.

What Are Extreme Conditions for Tungsten Carbide Tips?

Extreme conditions refer to environments where tools are exposed to high stress, pressure, temperature, and abrasion.

In such environments, traditional tools may fail due to wear, heat, or mechanical failure, but tungsten carbide tips thrive under these conditions.

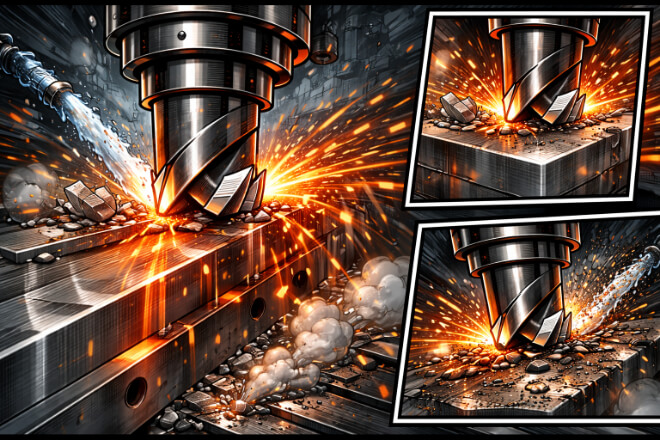

1). High-Pressure Environments

In industries like oil and gas drilling and mining, tools are often subjected to intense pressure.

Drilling through rock or deep underground operations generates significant mechanical stress on tools.

Tungsten carbide tips are engineered to handle these high-pressure situations without breaking, chipping, or deforming.

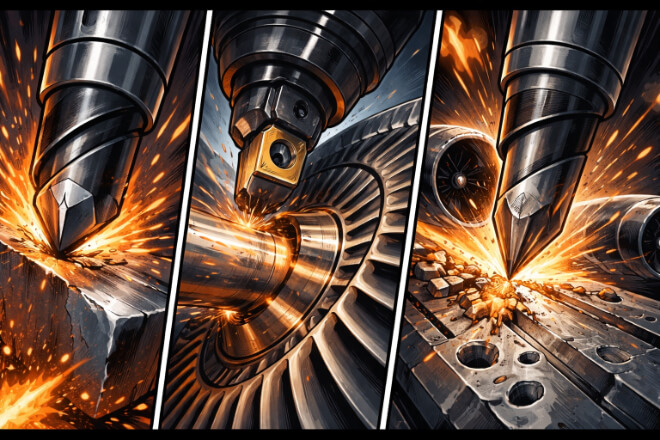

2). High-Temperature Environments

High-speed machining and cutting operations often generate substantial heat, which can cause traditional tools to lose their hardness.

Tungsten carbide tips, however, maintain their hardness and cutting edge even in extreme temperatures, making them ideal for high-temperature applications such as metalworking and aérospatial fabrication.

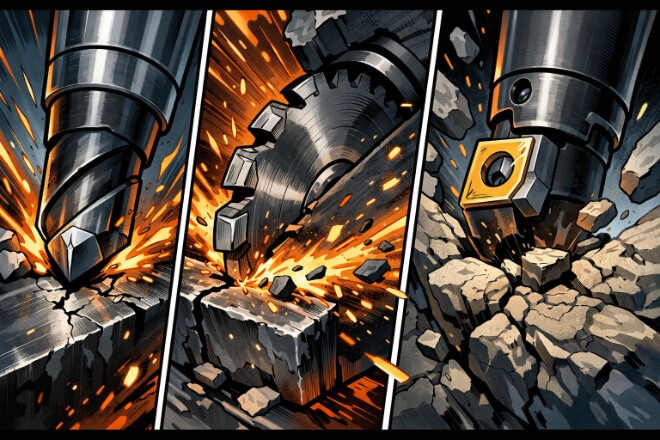

3). Abrasion and Wear

In environments where tools are exposed to abrasive materials like rocks, metals, or composites, wear can quickly degrade tool performance.

Tungsten carbide’s exceptional résistance à l'usure allows it to endure these abrasive conditions, maintaining its cutting ability longer than other materials.

How Tungsten Carbide Tips Perform Under High Stress

Tungsten carbide’s performance under stress is one of its key advantages in extreme conditions. Here’s how these tips excel under pressure and wear:

1). Dureté and Resistance to Deformation

Tungsten carbide is known for its hardness, which is essential in high-stress cutting and drilling applications.

The extreme hardness prevents the tool from deforming or losing its sharpness, even under intense pressure.

This hardness allows carbide tips to cut through tough materials, such as steel, titanium, and rock, without suffering from permanent deformation.

2). Dureté and Impact Resistance

In addition to being hard, tungsten carbide tips are also tough.

This combination of hardness and toughness makes them resistant to impact, meaning they can withstand shocks and sudden stresses, which would break or chip other tools.

In applications like mining or oil drilling, where tools experience frequent impact, carbide tips are a reliable choice.

3). Low Friction and Heat Buildup

High-stress cutting and drilling operations generate significant friction and heat.

Tungsten carbide’s low friction properties allow the tips to cut through materials smoothly without generating excessive heat.

This reduces the chances of the tool overheating or losing its cutting edge during operation, which is especially important in high-speed machining and other heat-intensive applications.

Tungsten Carbide Tips in High-Pressure Applications

Tungsten carbide tips are commonly used in applications where high pressure is a significant factor.

These environments require tools that can maintain their integrity under pressure without failing.

1). Pétrole et gaz Forage

In the oil and gas industry, drilling tools are exposed to extreme pressure when drilling deep into the Earth’s crust.

Tungsten carbide tips are used in drill bits to provide the necessary durability and résistance à l'usure to handle the pressures encountered during the drilling process.

These tips help prevent premature tool failure, ensuring smooth and continuous drilling operations.

2). Exploitation minière and Excavation

In mining operations, tungsten carbide tips are used for cutting and drilling into hard rocks and minerals.

The high pressure generated during rock excavation demands tools that can handle significant stress.

Tungsten carbide tips resist wear from abrasive materials and prevent deformation, improving productivity and reducing downtime.

3). Construction and Heavy Machinery

Construction and heavy machinery tools are subject to extreme pressure during tasks like trenching, digging, and cutting through dense materials.

Tungsten carbide tips provide the strength and durability required to withstand these pressures while maintaining cutting performance.

Tungsten Carbide Tips in High-Temperature Environments

High temperatures are another factor that can compromise tool performance, but tungsten carbide tips are well-suited to withstand extreme heat.

This makes them ideal for high-temperature machining, metal cutting, and aérospatial candidatures.

1). High-Speed Machining

In high-speed machining, cutting tools are subjected to rapid friction and heat buildup.

Tungsten carbide tips are capable of operating at high speeds without losing their dureté or becoming damaged due to heat.

This resistance to thermal degradation ensures that the tool maintains its performance over time, even in heat-intensive operations.

2). Travail des métaux and Steel Cutting

When cutting metals such as steel or alloys, significant heat is generated. Tungsten carbide tips’ heat resistance prevents the tool from softening or losing its cutting edge.

This ability to maintain performance under heat is essential in industries like automotive manufacturing, metalworking, and tooling.

3). Aérospatial and Jet Engine Manufacturing

In aerospace applications, tools must withstand high temperatures while cutting through tough materials such as titanium.

Tungsten carbide tips are essential in these applications, offering exceptional heat resistance and preventing deformation, ensuring the precision needed in high-performance aerospace components.

Benefits of Tungsten Carbide Tips in Extreme Conditions

Using tungsten carbide tips in extreme conditions offers numerous benefits that improve performance, tool life, and cost-effectiveness in harsh environments.

1). Improved Tool Life

The exceptional résistance à l'usure et dureté of tungsten carbide tips result in longer tool life, reducing the need for frequent replacements and downtime. This increases operational efficiency and reduces costs over time.

2). Increased Productivity

Tungsten carbide tips are able to maintain their cutting performance under high stress and extreme conditions, leading to increased productivity.

With carbide tips, operations can run continuously without interruptions caused by tool failure or wear.

3). Cost-Effectiveness

While tungsten carbide tips may have a higher initial cost, their extended tool life, reduced downtime, and improved productivity make them a cost-effective choice for businesses operating under extreme conditions.

The benefits far outweigh the initial investment, leading to long-term savings.

Conclusion

Tungsten carbide tips are ideal for use in extreme conditions due to their hardness, wear resistance, and ability to withstand high pressure and temperatures.

Whether in oil and gas drilling, mining, or aerospace manufacturing, carbide tips provide consistent performance, durability, and precision.

By choosing tungsten carbide tips for high-stress applications, businesses can improve productivity, reduce tool replacement costs, and enhance operational efficiency.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.