Tungsten carbide tips are known for their exceptional dureté et résistance à l'usure, making them ideal for challenging industrial applications.

However, even the toughest carbide tips can experience excessive wear, leading to decreased performance and increased costs.

Identifying the root causes of excessive wear and addressing them quickly can help extend the lifespan of these valuable tools.

In this article, we will explore the common causes of excessive wear on tungsten carbide tips and provide practical troubleshooting tips for improving tool longevity and performance.

Identifying the Signs of Excessive Wear on Tungsten Carbide Tips

Before you can troubleshoot the cause of excessive wear, it’s essential to know what signs to look for. Some common indicators of excessive wear include:

Visible Damage: This can include chipping, cracking, or visible signs of erosion on the cutting edge.

Reduced Cutting Efficiency: If the carbide tip is not cutting as effectively or requires more force, it may be due to wear.

Increased Heat Generation: Excessive wear can cause friction, leading to higher temperatures during machining.

Frequent Tool Replacement: If the tips are wearing out too quickly, it may be a sign that the conditions or maintenance practices are contributing to premature wear.

By identifying these signs early, you can take action to address the underlying issues before they lead to costly tool replacements and production delays.

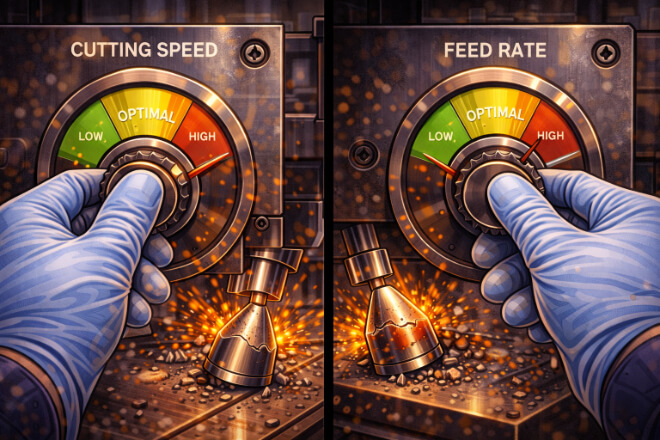

Incorrect Machining Parameters and Their Impact on Wear

One of the most common causes of excessive wear on tungsten carbide tips is the use of incorrect machining parameters.

Parameters such as speed, feed rate, and depth of cut all play a crucial role in tool performance and wear.

High Cutting Speed:

Running tools at speeds higher than recommended can cause excessive heat buildup, accelerating wear.

High speeds also increase the risk of thermal shock, which can damage the carbide tips.

Improper Feed Rate:

A feed rate that is too high or too low can lead to increased wear.

A high feed rate increases friction, while a low feed rate can cause the tip to drag, reducing cutting efficiency.

Excessive Depth of Cut:

If the depth of cut is too large, it can place too much pressure on the carbide tip, leading to premature wear.

To prevent excessive wear, ensure that all machining parameters are within the recommended specifications for the material being worked on.

Insufficient Coolant or Lubrication

Coolants and lubricants are critical in reducing friction and preventing excessive heat during machining operations.

If there is insufficient coolant or lubrication, the carbide tips can overheat, causing them to wear down more quickly.

Lack of proper coolant also increases the risk of corrosion, especially in humid or chemically aggressive environments.

Inadequate Coolant Flow: Ensure that the coolant is being applied correctly and in the right amount to maintain proper temperature control during the machining process.

Choosing the Wrong Lubricant: Not all lubricants are suitable for outils en carbure de tungstène. Always use a lubricant designed for high-performance cutting tools to reduce friction and extend tool life.

By ensuring proper coolant and lubrication management, you can significantly reduce the chances of excessive wear and maintain optimal tool performance.

Material Hardness and Compatibility Issues

Not all materials are equally compatible with tungsten carbide tips.

Tungsten carbide is hard and résistant à l'usure, but it can struggle with extremely hard or abrasive materials.

If the material being cut is too hard or abrasive, it can cause excessive wear on the carbide tips, even if all other conditions are ideal.

Harder Materials: When working with materials harder than the carbide, such as certain steels or ceramics, the tips will wear out more quickly.

Abrasive Materials: Materials like sand, concrete, and other abrasive substances can rapidly erode carbide tips.

To prevent excessive wear, choose tungsten carbide tips with appropriate dureté for the material being processed.

If working with particularly hard or abrasive materials, consider using tools with coatings that offer additional protection.

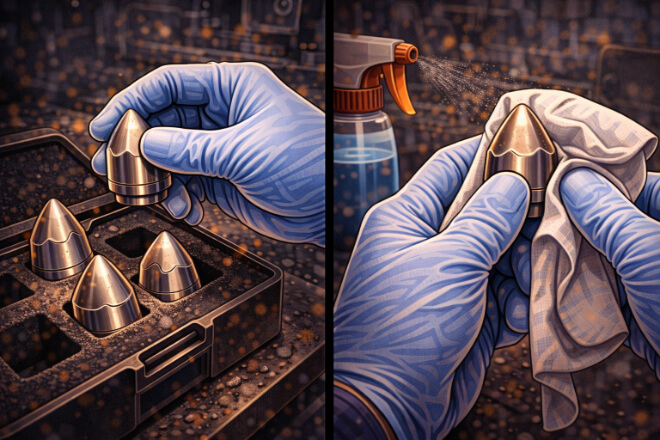

Poor Tool Handling and Maintenance Practices

Improper handling and maintenance practices can contribute to premature wear on tungsten carbide tips.

Mishandling during storage or improper mounting can cause damage to the tips, leading to quicker wear during use.

Incorrect Mounting: Make sure the carbide tips are mounted correctly on the machinery. Misalignment can cause uneven wear, leading to reduced tool life.

Poor Storage Conditions: Storing carbide tips in high-humidity or dirty environments can lead to corrosion or contamination, which accelerates wear.

Failure to Clean Tools: Regular cleaning of tungsten carbide tips is important to remove any debris or material buildup that can cause uneven wear and damage.

Establishing good tool handling and maintenance practices will reduce the likelihood of excessive wear and ensure the tips perform at their best for longer periods.

Inconsistent Quality of Tungsten Carbide Tips

The quality of the tungsten carbide tips themselves can also affect wear rates.

Poor-quality carbide tips may not have the same hardness or resistance to wear as high-quality ones, leading to faster degradation under the same working conditions.

Substandard Manufacturing: Some carbide tips may be made with inconsistent materials or improper manufacturing processes, which can result in defects that lead to rapid wear.

Low-Grade Carbide: Ensure that the carbide used for the tips is of high quality. Low-grade carbide may not be as durable, leading to premature failure.

Choosing high-quality, reliable carbide tips from reputable manufacturers will help reduce the frequency of excessive wear.

Conclusion

Excessive wear on tungsten carbide tips can be a significant issue that affects tool performance and overall production efficiency.

By understanding the common causes of wear, such as improper machining parameters, insufficient coolant, material compatibility, and poor tool handling, you can take steps to prevent or minimize wear.

Regular maintenance and the use of high-quality carbide tips will ensure your tools last longer and perform at their best.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.