Dans les usines modernes, les temps d'arrêt peuvent coûter cher. Lorsque les machines cessent de fonctionner, la production ralentit, les commandes sont retardées et les entreprises perdent de l'argent. Pour éviter cela, de nombreux fabricants utilisent des outils de coupe en carbure de tungstène. Ces outils sont réputés pour leur robustesse, leur durabilité et leur longue durée de vie.

Dans cet article, nous expliquerons comment les outils de coupe en carbure de tungstène aident à réduire les temps d’arrêt et pourquoi ils constituent un choix judicieux pour tout processus de fabrication.

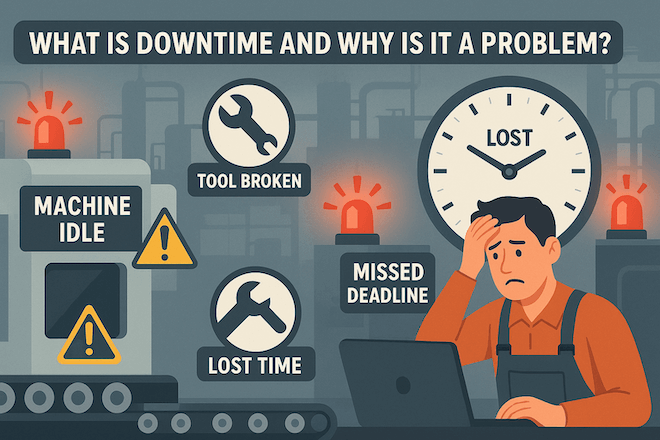

Qu’est-ce qu’un temps d’arrêt et pourquoi est-ce un problème ?

Un temps d'arrêt est une période pendant laquelle une machine ou une ligne de production ne fonctionne pas. Cela peut se produire pour plusieurs raisons :

L'outil de coupe se casse ou s'use

Les machines ont besoin d'entretien ou de réparation

La production doit s'arrêter pour changer d'outils

Les temps d’arrêt entraînent de nombreux problèmes :

Baisse de la production

Délais manqués

Des coûts de main-d'œuvre et d'énergie plus élevés

Bénéfices réduits

C'est pourquoi il est important de choisir des outils de coupe solides et fiables, comme outils en carbure de tungstène — pour aider à maintenir la production en marche.

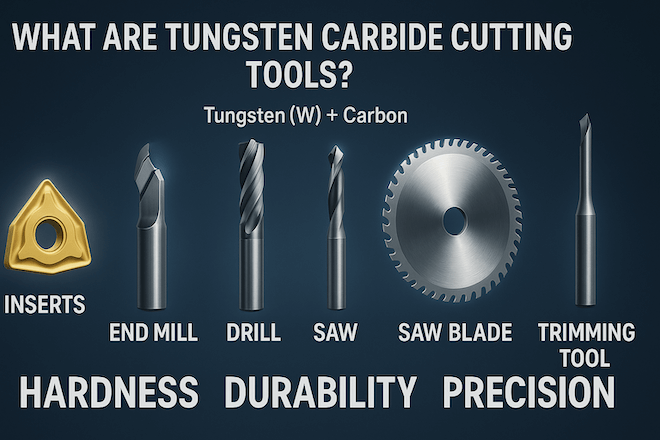

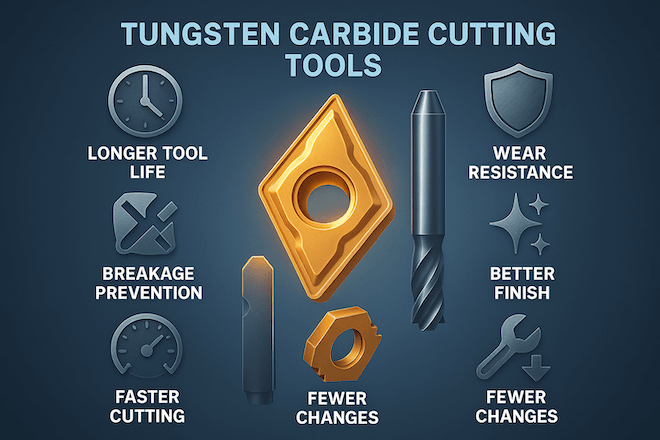

Que sont les outils de coupe en carbure de tungstène ?

Le carbure de tungstène est un matériau très dur, composé de tungstène (W) et de carbone (C). Il est beaucoup plus dur que l'acier ordinaire. Les outils de coupe en carbure de tungstène sont :

Plus fort

Plus fort

Plus résistant à l'usure et à la chaleur

Les types courants d’outils de coupe en carbure de tungstène comprennent :

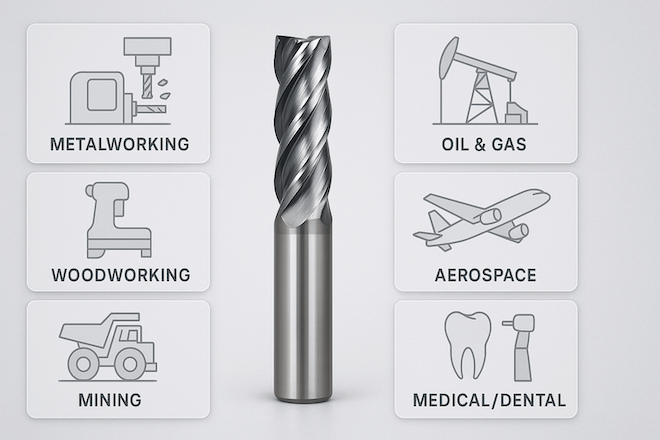

Ces outils sont utilisés dans de nombreux secteurs tels que travail des métaux, travail du bois, exploitation minière, et fabrication aérospatiale.

Comment les outils en carbure de tungstène réduisent les temps d'arrêt

Explorons les principales raisons pour lesquelles les outils en carbure de tungstène aident à réduire les temps d’arrêt des machines dans les usines :

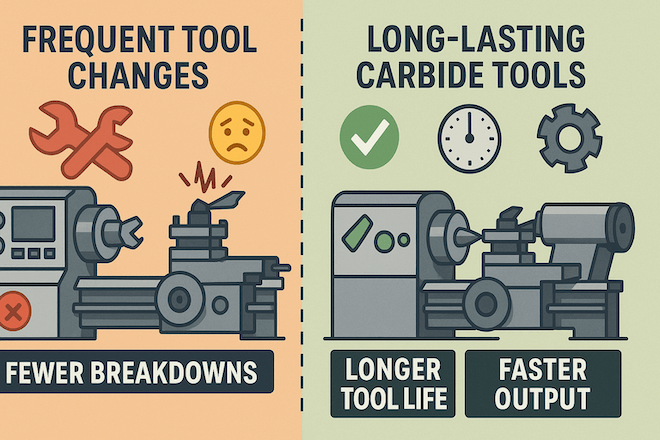

1. Durée de vie de l'outil plus longue

Les outils en carbure de tungstène durent 3 à 10 fois plus longtemps que les outils en acier classiques. Pour cette raison :

Vous changez d’outils moins souvent

Le remplacement des outils prend moins de temps

Moins d'interruptions de production

Cela signifie moins d’arrêts de machines et plus de temps de fabrication des produits.

2. Meilleure résistance à l'usure

Sur les lignes de production rapides, les outils sont soumis à de fortes frictions et à une forte chaleur. Les outils classiques s'usent rapidement. En revanche, les outils en carbure résistent :

Abrasion

Températures élevées

Déformation

Même lors de la coupe de matériaux résistants comme l'acier inoxydable, le carbure de tungstène reste solide.

3. Moins de casses d'outils

Un outil cassé arrête toute la chaîne de production. Les outils en carbure de tungstène sont moins susceptibles de casser sous de lourdes charges ou à des vitesses élevées, ce qui :

Assure le bon fonctionnement des machines

Évite les arrêts inattendus

Permet de gagner du temps et de réduire les coûts de réparation

4. Meilleure finition de surface

Grâce à leur affûtage plus durable, les outils de coupe en carbure de tungstène offrent des coupes de meilleure qualité et des finitions plus lisses. Cela réduit le besoin de :

Étapes de finition supplémentaires

Réusinage de pièces défectueuses

Retards d'inspection

Moins de problèmes signifient des flux de travail plus rapides et moins de temps d'arrêt.

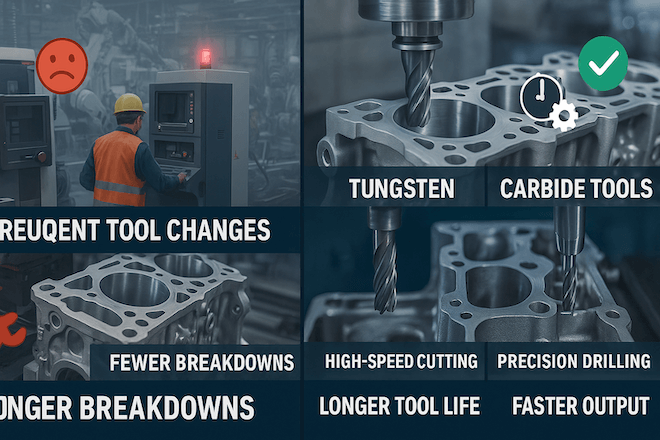

5. Vitesses de coupe plus rapides

Les outils en carbure de tungstène permettent des vitesses de travail plus élevées. Un usinage plus rapide vous permet :

Fabriquer plus de pièces en moins de temps

Terminez les tâches plus rapidement

Réduire le temps d'inactivité des machines

Cela améliore l’efficacité globale de l’usine.

6. Changements d'outils moins fréquents

Les outils en carbure durent souvent plus longtemps entre chaque remplacement. Par exemple, plaquettes en carbure Peut gérer de longues séries de production sans nécessiter de remplacement. Cela permet d'économiser :

Temps de l'opérateur

Temps d'arrêt pour la configuration des outils

Coûts de main-d'œuvre

Exemple concret : outils en carbure dans la fabrication automobile

Dans l'industrie automobile, rapidité et précision sont essentielles. Chaque seconde d'arrêt peut coûter cher. De nombreuses entreprises utilisent outils de coupe en carbure à:

Blocs moteurs coupés

Pièces de transmission de machines

Composants de suspension de forage

Parce que ces pièces requièrent de la précision et sont fabriquées à partir de matériaux durs, le carbure de tungstène est le choix idéal. Il réduit les temps de changement d'outil et évite les pannes en cours de production.

Applications des outils en carbure de tungstène

Les outils de coupe en carbure de tungstène sont utilisés dans de nombreuses industries, notamment :

Travail des métaux et usinage CNC

Travail du bois et découpage de papier

À Refaire, nous proposons une large gamme de solutions carbure pour toutes ces applications.

Résumé des avantages

Voici un bref résumé de la manière dont les outils de coupe en carbure de tungstène contribuent à réduire les temps d’arrêt :

| Avantage | Comment cela réduit les temps d'arrêt |

|---|---|

| Durée de vie de l'outil plus longue | Moins de temps consacré aux remplacements |

| Résistance à l'usure | Moins de pannes d'outils |

| Résistance à la rupture | Réduction des arrêts d'urgence |

| Rétention des bords tranchants | Meilleure qualité de produit, moins de retouches |

| Vitesse de coupe élevée | Production plus rapide, moins de retards |

| Des performances fiables | Moins d'entretien des machines |

Pourquoi choisir Retop pour les outils en carbure de tungstène ?

Chez Retop, nous sommes spécialisés dans les outils en carbure de tungstène haute performance. Forts de plus de 14 ans d'expérience et exportant vers plus de 50 pays, nous proposons :

Conception d'outils personnalisés

Matériaux de haute qualité

Contrôle de qualité strict

Livraison rapide dans le monde entier

Support technique expert

Que vous ayez besoin lames de scie au carbure ou outils pour sièges de soupape, Retop est votre partenaire de confiance.

Conclusion

Les temps d'arrêt constituent un problème majeur dans le secteur manufacturier, mais la solution est simple : utiliser des outils de coupe en carbure de tungstène. Ces outils réduisent les changements d'outils, résistent à l'usure et durent plus longtemps, vous permettant ainsi de maintenir vos machines en fonctionnement et de respecter les délais de production.

Si vous souhaitez augmenter votre efficacité et réduire vos coûts, choisissez les outils en carbure de Retop, conçus pour durer et performants.