Dans l'usinage moderne, l'usure des outils est l'un des plus grands défis. Une usure trop rapide des outils entraîne des finitions médiocres, un ralentissement de la production et des coûts plus élevés.

C'est pourquoi la résistance à l'usure est importante, et c'est là que outils de coupe en carbure de tungstène briller vraiment.

Le carbure de tungstène n'est pas un simple matériau d'outillage. C'est l'un des matériaux les plus durs et les plus résistants à l'usure, ce qui le rend idéal pour les travaux d'usinage exigeants.

Mais qu'est-ce qui le rend si durable ? Et comment surpasse-t-il les matériaux d'outillage traditionnels comme l'acier rapide ?

Cet article explique tout cela en termes simples. Que vous dirigiez un atelier d'usinage CNC ou que vous travailliez avec des matériaux difficiles, nous vous expliquerons pourquoi les outils en carbure de tungstène sont le choix judicieux pour des performances durables.

1. Qu’est-ce que la résistance à l’usure des outils de coupe ?

Résistance à l'usure C'est la capacité d'un outil coupant à rester affûté et fonctionnel après une utilisation prolongée. Lorsqu'un outil coupe du métal, du plastique ou du bois, ses arêtes sont orientées vers :

Chaleur

Friction

Pression

Matériaux abrasifs

Au fil du temps, l'outil s'émousse, s'écaille ou se casse. Les outils peu résistants à l'usure perdent en précision et peuvent entraîner des défauts dans vos pièces.

Avec une bonne résistance à l'usure :

L'outil dure plus longtemps

La finition de surface reste propre

Vous réduisez les temps d'arrêt et les coûts de remplacement

C'est pourquoi la résistance à l'usure est l'un des facteurs les plus importants lors du choix des outils de coupe.

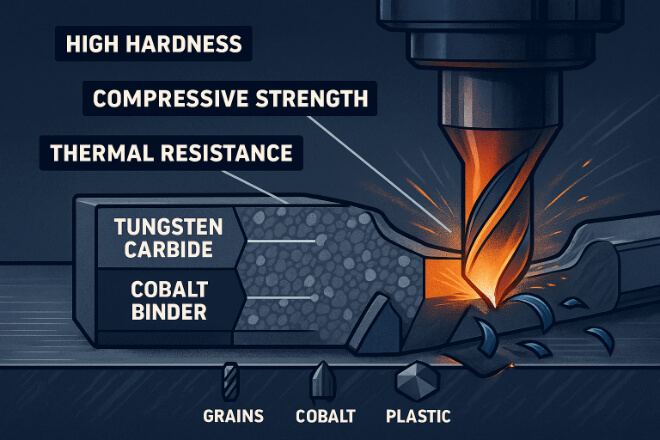

2. Qu'est-ce qui rend le carbure de tungstène si résistant à l'usure ?

Le carbure de tungstène est un composé composé de tungstène et de carbone, combiné à un liant métallique comme le cobalt.

Ensemble, ils forment un matériau dense et extrêmement dur qui résiste à l’usure bien mieux que les aciers à outils ordinaires.

Voici les principales raisons pour lesquelles il fonctionne si bien :

1). Élevé Dureté

Le carbure de tungstène est deux fois plus dur que l'acier

Il se classe environ 9 sur l'échelle de Mohs, juste en dessous des diamants

Cette dureté lui permet de couper des matériaux durs sans les émousser.

2). Excellente résistance à la compression

Peut supporter des forces de coupe très élevées

Ne se déforme pas facilement sous la pression

3). Haute résistance thermique

Maintient la dureté même à des températures élevées

Peut couper à des vitesses plus rapides sans ramollir

4). Faible taux d'usure

La structure à grains fins résiste à l'abrasion des copeaux et des surfaces dures

Garde les bords plus nets pendant de plus longues périodes

Toutes ces propriétés font du carbure de tungstène le matériau idéal lorsque l’usure des outils est une préoccupation.

3. Types d'usure des outils auxquels le carbure de tungstène peut résister

Les outils subissent différents types d'usure lors de la coupe. Les outils en carbure de tungstène sont conçus pour les gérer tous :

| Type d'usure | Description | Résistance au carbure |

|---|---|---|

| Usure abrasive | Les copeaux frottent contre la surface de l'outil | Excellent |

| Usure adhésive | Le matériau adhère au bord de l'outil | Très bien |

| Usure par diffusion | La chaleur provoque une perte de matière sur le bord | Excellent |

| Usure chimique | Réaction entre l'outil et la pièce | Fort |

| Écaillage des bords | Le tranchant se brise sous la pression | Haute ténacité (avec la bonne nuance) |

4. Comparaison : carbure de tungstène et acier rapide (HSS)

Comparons la manière dont les outils en carbure se comparent à l'acier rapide traditionnel (HSS) en matière de résistance à l'usure.

| Propriété | Carbure de tungstène | Acier rapide |

|---|---|---|

| Dureté | 1600–1800 HT | 600–900 HV |

| Résistance à la chaleur | Excellent | Modéré |

| Résistance à l'usure | Supérieur | Modéré |

| Durée de vie de l'outil | 3 à 10 fois plus long | Plus court |

| Cas d'utilisation idéaux | Matériaux durs et abrasifs | Métaux plus tendres, coupes à basse vitesse |

Ainsi, même si l'acier rapide est moins cher, il s'use plus rapidement. Cela implique davantage de changements d'outils, davantage de temps d'arrêt et un coût total plus élevé.

5. Avantages réels de la résistance à l'usure du carbure dans votre atelier

Voici ce que signifie réellement une meilleure résistance à l’usure pour vos opérations quotidiennes :

1). Durée de vie de l'outil plus longue

Vous n'avez pas besoin de remplacer vos outils en carbure aussi souvent, ce qui réduit les coûts d'outillage et augmente la productivité.

2). Meilleure finition de surface

Les bords tranchants durent plus longtemps, ce qui signifie des coupes plus nettes et des surfaces de pièces plus lisses, même sur de longues séries de production.

3). Vitesses de coupe plus élevées

Parce que le carbure résiste mieux à la chaleur, vous pouvez faire fonctionner vos machines plus rapidement sans nuire à la durée de vie de l'outil.

4). Précision améliorée

Des outils usés entraînent des imprécisions dimensionnelles. Les outils en carbure restent constants, garantissant ainsi la conformité des pièces.

5). Moins de changements d'outils

Moins de temps d’arrêt, moins d’interruptions et une meilleure efficacité pour vos opérateurs CNC.

6. Quelles industries comptent sur la résistance à l’usure du carbure ?

Les outils en carbure de tungstène sont utilisés dans tous les secteurs nécessitant la découpe de matériaux durs ou abrasifs. Voici quelques secteurs courants :

1). Aérospatial

Découpe du titane, de l'Inconel et des aciers à haute résistance

La longue durée de vie de l'outil réduit les temps d'arrêt coûteux

2). Automobile

Usinage à grande vitesse de l'acier trempé et de la fonte

Précision constante dans les pièces du moteur et des freins

Micro-outils pour implants et composants chirurgicaux

La netteté et la résistance à l'usure garantissent sécurité et précision

4). Pétrole et gaz

Outils pour le perçage, le filetage de tuyaux et l'usinage de vannes

Gère les matériaux abrasifs et les conditions extrêmes

5). Travail du bois et composites

Lames de scie et fraises à pointe en carbure

Idéal pour le MDF, les panneaux de particules et la fibre de verre

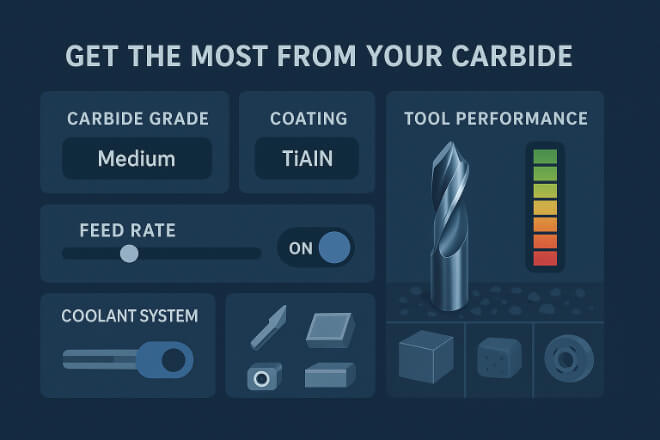

7. Facteurs affectant la résistance à l'usure du carbure

Même si le carbure est naturellement résistant à l’usure, plusieurs facteurs peuvent améliorer ou réduire ses performances :

1). Nuance de carbure

Grain ultra-fin pour la résistance à l'usure des outils de finition

Nuances plus grossières pour l'ébauche et la résistance aux chocs

2). Revêtement d'outils

Les revêtements TiAlN, AlCrN et DLC réduisent la friction et la chaleur

Protégez la surface de l'outil et prolongez sa durée de vie

3). Avance et vitesse

Faire fonctionner les outils à des vitesses appropriées empêche la rupture des bords

Des vitesses plus élevées fonctionnent bien avec le carbure mais doivent être contrôlées

4). Liquide de refroidissement et lubrification

Aide à réduire la chaleur et à éliminer les copeaux

Améliore considérablement la durée de vie de l'outil

8. Le carbure vaut-il l’investissement ?

Certaines personnes hésitent à opter pour des outils en carbure en raison de leur prix plus élevé. Mais si l'on prend en compte la résistance à l'usure, ils représentent souvent le meilleur rapport qualité-prix.

Décomposons-le :

| Facteur | Outil HSS | Outil en carbure |

|---|---|---|

| Coût initial | Faible | Plus haut |

| Durée de vie de l'outil | Court (1 à 3 heures) | Longue (10 à 20 heures et plus) |

| Finition de surface | Modéré | Excellent |

| Nombre de remplacements | Beaucoup | Peu |

| Temps d'arrêt | Fréquent | Rare |

| Coût par pièce | Supérieur (indirect) | Inférieur |

En résumé : les outils en carbure sont rentables car ils durent plus longtemps, fonctionnent plus rapidement et réduisent les reprises.

Réflexions finales

Les outils de coupe en carbure de tungstène se distinguent pour une raison simple : ils durent plus longtemps.

Grâce à leur résistance à l’usure exceptionnelle, ils aident les ateliers d’usinage et les fabricants à économiser de l’argent, à produire de meilleures pièces et à accroître leur efficacité.

Si vous en avez assez des outils usés qui ralentissent votre production, il est temps de passer à l'action. Le carbure de tungstène est non seulement plus résistant, mais aussi plus intelligent.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.