Outils de coupe en carbure de tungstène have become a standard in modern metalworking.

Their ability to handle tough materials, keep sharp edges, and work at high speeds makes them an essential choice for manufacturers, workshops, and large-scale industrial operations.

If your business works with metals such as steel, stainless steel, titanium, or alloys, using the right cutting tools can be the difference between average results and exceptional output.

In this guide, we will explore what makes tungsten carbide cutting tools ideal for metal, their applications, benefits, and how to choose and maintain them for the best performance.

Why Tungsten Carbide is Ideal for Metal Cutting

Tungsten carbide is a compound made of tungsten and carbon atoms. It is extremely hard—almost as hard as diamond—and can withstand high temperatures without losing strength. For metal cutting, these properties are vital.

Key Advantages in Metal Cutting

Haut dureté – Maintains sharp cutting edges even after long use.

Résistance à l'usure – Slows down tool wear, reducing replacement frequency.

Heat resistance – Can work at high cutting speeds without damage.

Versatility – Works with both ferrous and non-ferrous metals.

Dimensional accuracy – Produces consistent, precise parts.

Applications of Tungsten Carbide Cutting Tools in Metalworking

Tungsten carbide tools are used in a wide range of metalworking tasks, from heavy-duty industrial processes to precision machining. Some common uses include:

Turning and milling – For shaping metals with high precision.

Drilling – Creating holes in tough materials like stainless steel.

Threading – Producing accurate threads in hard metals.

Boring – Enlarging existing holes with accuracy.

Cutting and grooving – Creating slots and cuts in various metals.

Types of Tungsten Carbide Cutting Tools for Metal

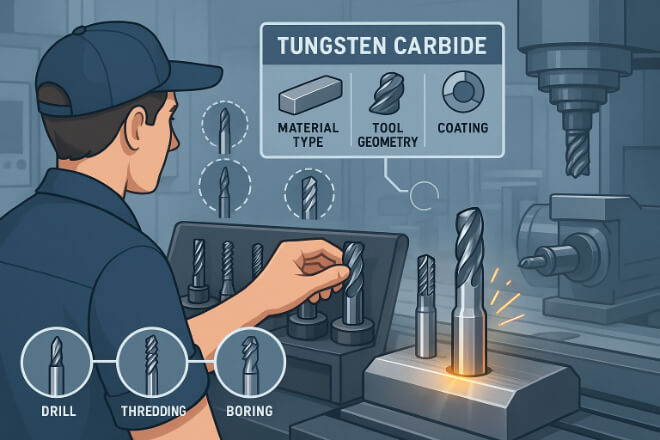

Different tools are designed for different tasks. Choosing the right one depends on the metal type, required precision, and production speed.

| Type d'outil | Metalworking Application |

|---|---|

| Plaquettes en carbure | Turning, facing, and profiling metals |

| Fraises en carbure | Milling slots, edges, and surfaces |

| Forets en carbure | Drilling holes in steel and alloys |

| fraises en carbure | Deburring and shaping metal parts |

| Alésoirs en carbure | Finishing holes to precise sizes |

How to Choose the Right Tungsten Carbide Cutting Tool for Metal

Selecting the right tool involves understanding your material, the cutting speed required, and the finish quality expected.

Match tool grade to material – Use tougher grades for harder metals and wear-resistant grades for softer metals.

Consider coating – Coatings like TiN or TiAlN improve tool life when cutting high-strength metals.

Select the right geometry – The tool’s edge angle and flute design affect cutting efficiency.

Account for speed and feed – Follow manufacturer recommendations for optimal results.

Best Practices for Using Tungsten Carbide Cutting Tools on Metal

To get the best results, proper use is just as important as choosing the right tool.

| Meilleures pratiques | Avantage |

|---|---|

| Use Correct Cutting Speeds | Prevents overheating and tool damage |

| Apply Proper Coolant | Reduces heat and improves finish |

| Secure Workpiece Firmly | Minimizes vibration and increases accuracy |

| Check Tool Wear Regularly | Avoids poor finish and tool breakage |

| Follow Manufacturer Guidelines | Ensures optimal performance and safety |

Maintaining Tungsten Carbide Cutting Tools for Long Life

Proper maintenance keeps tools sharp and reliable.

Clean after use – Remove metal chips and coolant residue.

Store in protective cases – Prevents chipping and corrosion.

Regrind when needed – Sharp edges improve cutting quality.

Avoid misuse – Do not use tools for unsuitable materials.

Cost Considerations for Tungsten Carbide Cutting Tools

While these tools may cost more than high-speed steel, they last much longer, reduce downtime, and improve product quality. This results in a lower cost per part over time.

Factors affecting cost:

Tool grade and size

Coating type

Brand and supplier

Order volume

Conclusion

For any company working with metals, tungsten carbide cutting tools are a smart investment.

They offer exceptional performance, durability, and efficiency that can lead to better quality products and reduced production costs.

By selecting the right tool, using it correctly, and maintaining it well, decision-makers can ensure maximum value and long-term benefits.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.