Composants d'usure en carbure de tungstène are critical in the oil and gas sector. They keep drilling rigs, pumps, valves, and processing equipment running longer under extreme conditions.

For decision-makers in this industry, knowing how and why these parts are used can help in selecting the right suppliers, improving equipment performance, and cutting maintenance costs.

This article explains the unique role of tungsten carbide wear parts in pétrole et gaz, from their properties to the key applications and benefits. We will also explore how to make smart purchasing decisions for these components.

What Are Tungsten Carbide Wear Components?

Tungsten carbide wear components are parts made from a mix of poudre de carbure de tungstène and a binder metal, usually cobalt or nickel.

Tungsten carbide is extremely hard — close to diamond on the dureté scale — while the binder gives toughness and reduces brittleness.

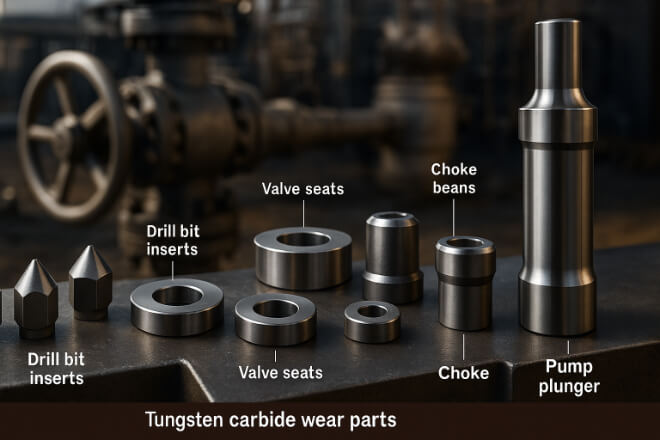

In the oil and gas industry, these components include:

Drill bit inserts

Valve seats and sleeves

Choke beans and nozzles

Pump plungers and liners

Wear-resistant sleeves for downhole tools

They are used where standard steel parts would quickly wear out due to sand, rock, high temperatures, and corrosive fluids.

Why Oil & Gas Needs Tungsten Carbide

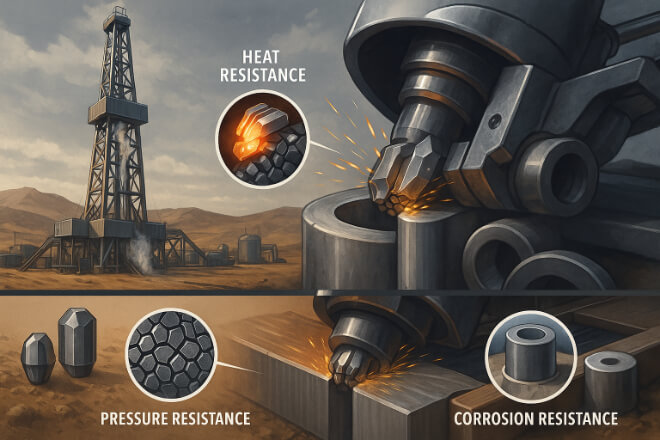

The oil and gas sector is one of the harshest working environments for machinery. Equipment faces:

Abrasive particles like sand and rock

High pressure deep underground

High temperatures in drilling and production

Corrosive fluids including saltwater, acids, and chemicals

Normal steel parts may fail quickly under these conditions. Tungsten carbide’s hardness allows it to resist wear, while its heat and corrosion resistance ensures long-term reliability.

For operators, this means:

Longer equipment life

Fewer shutdowns

Lower replacement costs

Safer operations

Properties That Make Tungsten Carbide Ideal for Oil & Gas

The reason tungsten carbide is preferred in oil and gas is because of its unique combination of properties:

| Propriété | Benefit in Oil & Gas |

|---|---|

| Dureté élevée | Resists wear from sand, rock, and metal-to-metal contact |

| Haute résistance à la compression | Withstands extreme drilling pressures |

| Résistance à la chaleur | Maintains strength at high downhole temperatures |

| Résistance à la corrosion | Works in saltwater, acidic, and chemical environments |

| Stabilité dimensionnelle | Keeps precise shape even after long use |

These qualities directly translate to higher productivity and lower maintenance costs for drilling and processing operations.

Key Applications in Oil & Gas

1). Drill Bit Inserts

Tungsten carbide inserts are fitted into roller cone and PDC drill bits. They crush and cut through rock while withstanding high impacts and abrasion.

Benefit: Longer drilling runs and fewer trips to replace bits.

2). Valve Seats and Sleeves

In oil and gas pipelines, tungsten carbide valve seats and sleeves control flow and seal under high pressure.

Benefit: Reliable sealing in high-pressure, abrasive, and corrosive conditions.

3). Choke Beans and Nozzles

Used in choke manifolds to control flow from wells, these parts face high-speed abrasive fluids.

Benefit: Extended service life and stable flow control.

4). Pump Plungers and Liners

High-pressure pumps in oil production use tungsten carbide plungers and liners to handle abrasive slurries.

Benefit: Reduced pump downtime and lower replacement frequency.

5). Downhole Tool Sleeves

Directional drilling tools often have tungsten carbide sleeves to prevent wear on critical surfaces.

Benefit: Protects expensive tools and reduces the risk of downhole failures.

How These Parts Are Manufactured

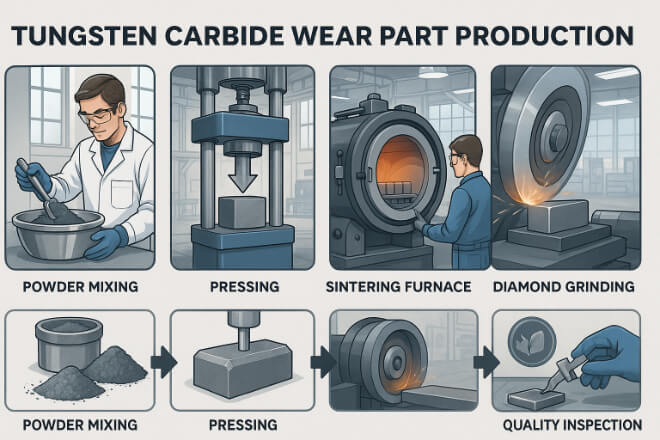

The production of tungsten carbide wear parts for oil and gas follows a precise process:

Powder Preparation – Tungsten carbide powder is mixed with a binder for toughness.

Pressing – Powder is pressed into shape using uniaxial or isostatic pressing.

Sintering – Parts are heated in a furnace to fuse the powder into a dense, solid component.

Finishing – Diamond grinding ensures precise dimensions.

Coating (Optional) – Some parts are coated for extra wear or corrosion resistance.

Choosing the Right Tungsten Carbide Components

For oil and gas operations, the wrong choice can mean costly downtime. Decision-makers should consider:

1). Grade Selection

Different tungsten carbide grades balance dureté et dureté.

Harder grades last longer in abrasive conditions, while tougher grades resist impact better.

2). Coating Options

Coatings like TiN, TiC, or diamond-like carbon can further extend service life.

3). Quality Standards

Choose suppliers who follow ISO or API standards for pétrole et gaz equipment.

4). Supplier Support

Suppliers who offer technical advice can help match the right grade and design to your application.

Cost vs. Value

While tungsten carbide components cost more upfront than steel, they save money over time by:

Reducing replacement frequency

Cutting downtime costs

Improving safety and reliability

In high-cost pétrole et gaz operations, the return on investment is usually fast.

Conclusion

Tungsten carbide wear components are not just a luxury in oil and gas — they are essential for safe, efficient, and profitable operations.

Their unmatched hardness, strength, and resistance to heat and corrosion make them the go-to choice for drilling, pumping, and flow control applications.

For decision-makers, investing in the right tungsten carbide parts means better performance, fewer failures, and long-term savings.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.