In the woodworking and cutting industry, efficiency, precision, and durability are key to staying competitive. Carbide wear components have become the preferred choice for companies that need high-performance tools.

Made from tungsten carbide or other carbide materials, these components resist wear, maintain sharpness longer, and work well even under heavy use.

This makes them essential for sawmills, furniture production, and large-scale cutting operations.

In this article, we explore what carbide wear components are, how they are used in woodworking and cutting applications, and why they bring such strong value to manufacturers.

What Are Carbide Wear Components?

Carbide wear components are parts made from extremely hard materials, usually tungsten carbide, bonded with cobalt or nickel.

They are designed to withstand continuous friction, pressure, and impact without losing performance.

Common examples include:

Saw tips for circular saws and band saws

Cutting knives for wood planers

Router bits for shaping wood

Insert tooling for CNC woodworking machines

These parts offer higher hardness than steel and maintain sharp edges much longer.

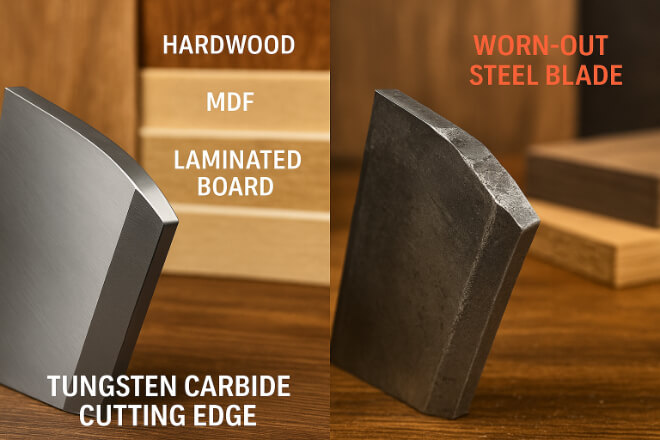

Why Carbide Is Ideal for Woodworking

Woodworking tools face constant contact with abrasive materials such as hardwood, MDF, and laminated boards.

This contact dulls conventional steel quickly. Carbide components stand out because they:

Stay sharp longer – Reducing downtime for sharpening.

Cut faster – Allowing higher production rates.

Handle tough materials – Including plywood, composites, and exotic hardwoods.

Lower long-term costs – Fewer replacements mean better ROI.

Common Applications in Woodworking

| Application | Carbide Component | Avantage |

|---|---|---|

| Sawmills | Carbide-tipped saw blades | Longer blade life and cleaner cuts |

| Furniture making | Router bits and shaper cutters | Precision shaping of complex profiles |

| Flooring production | Carbide knives | High-speed cutting with smooth finish |

| Plywood & MDF cutting | Carbide saw tips | Resist wear from glue and resin |

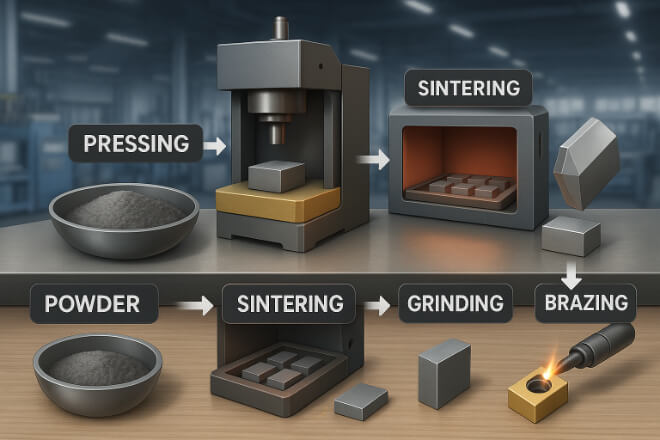

How Carbide Wear Components Are Made

The manufacturing process for carbide wear components includes:

Powder mixing – Poudre de carbure de tungstène mixed with a binder.

Pressing – Shaped into the desired form.

Sintering – Heated to bond the particles for maximum strength.

Grinding and finishing – Precision shaping for accuracy.

Brazing or mounting – Fixed to steel tool bodies.

This process results in parts that are both hard and tough, able to handle repetitive cutting without failure.

Benefits for Decision-Makers

For company leaders in woodworking and cutting operations, switching to carbide wear components can deliver:

Higher productivity – Machines run longer without downtime.

Better quality products – Consistent, smooth cuts reduce waste.

Cost savings – Lower replacement frequency reduces inventory costs.

Competitive edge – Ability to process harder materials expands market opportunities.

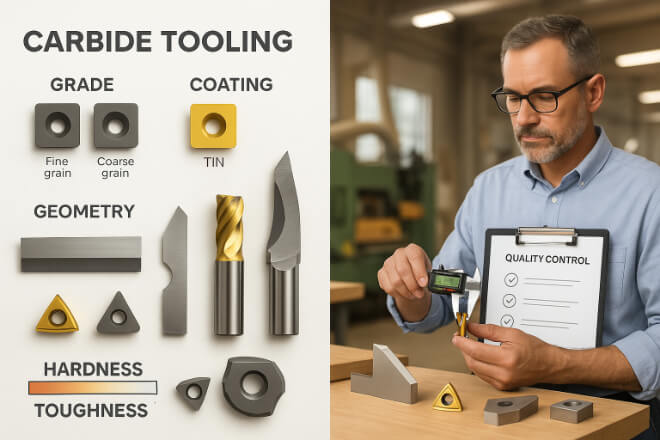

Choosing the Right Carbide Wear Components

When selecting carbide components for woodworking, consider:

Grade of carbide – Harder grades last longer but may be more brittle.

Coating options – Some have special coatings for extra wear resistance.

Tool design – Shape and geometry affect performance.

Supplier reliability – Consistent quality is key.

Conclusion

Carbide wear components are transforming woodworking and cutting operations worldwide. They bring longer tool life, better quality results, and cost savings, making them a smart investment for manufacturers.

For decision-makers looking to improve production efficiency and product quality, tungsten carbide is a proven choice.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.