bagues en carbure de tungstène are known for their incredible dureté, résistance à l'usure, et dureté, making them ideal for demanding industrial applications.

However, when exposed to harsh environments—especially those involving chemicals, salts, and moisture—tungsten carbide can suffer from corrosion, leading to reduced performance and premature failure.

To combat this, various anti-corrosion treatments have been developed to improve the longevity and reliability of tungsten carbide bushings in corrosive environments.

This article explores the different anti-corrosion treatments available for tungsten carbide bushings, their benefits, and how they help extend the life of equipment in industries such as exploitation minière, pétrole et gaz, chemical processing, and more.

What is Corrosion and Why is it a Problem for Tungsten Carbide Bushings?

Corrosion refers to the gradual degradation of materials, typically metals, due to chemical reactions with their environment.

In the case of tungsten carbide bushings, corrosion occurs when the binder material, often cobalt or nickel, reacts with acids, salts, moisture, or other aggressive chemicals.

1.1). Corrosion Effects:

Weakening of the bushing’s structure

Loss of dimensional stability

Decreased résistance à l'usure

Durée de vie raccourcie

While tungsten carbide itself is highly resistant to wear, the binder materials are more prone to corrosion, which can cause the entire bushing to fail.

Anti-corrosion treatments aim to protect the binder and prevent these issues.

Types of Anti-Corrosion Treatments for Tungsten Carbide Bushings

There are several effective anti-corrosion treatments for tungsten carbide bushings.

Each treatment has its specific application and provides protection against different types of corrosion. Here are the most commonly used methods:

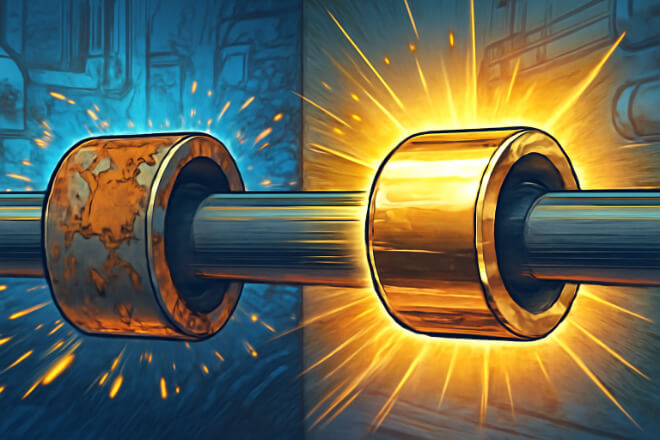

1). Surface Coatings

Surface coatings are one of the most effective ways to protect tungsten carbide bushings from corrosion.

Coatings act as a barrier, preventing corrosive substances from coming into contact with the material.

1.1). Popular Coatings for Tungsten Carbide Bushings:

Titanium Nitride (TiN): TiN is a hard, durable coating known for its résistance à la corrosion et résistance à l'usure. It forms a protective layer that helps to prevent corrosion in acidic and alkaline environments.

Diamond-Like Carbon (DLC): DLC coatings offer ultra-low friction and excellent corrosion resistance. DLC is often used in high-performance applications where bushings are exposed to chemicals and high temperatures.

Chromium (Cr) Coating: Chromium coatings are highly resistant to both abrasion and corrosion, making them ideal for bushings used in harsh, abrasive environments such as mining or chemical processing.

1.2). Why Choose Surface Coatings?

Enhanced Protection: Surface coatings create a protective layer, significantly extending the life of the bushing in corrosive environments.

Improved Performance: Coatings can also improve the friction and wear resistance of the bushings, leading to fewer maintenance needs and reduced downtime.

2). Plasma Spray Coating

Plasma spray coating involves heating a coating material (often metal or ceramic) to a molten state and spraying it onto the surface of the bushing.

This method provides a thick and durable coating that offers excellent protection against corrosion, high temperatures, and wear.

2.1). Benefits:

High resistance to corrosive chemicals and abrasion

Ability to coat irregular shapes and hard-to-reach areas

Provides excellent thermal resistance

Plasma spray coatings are especially useful for bushings in extreme environments, such as those in the oil & gas industry or marine applications.

3). Electroplating

Electroplating is a method where a thin layer of metal, typically nickel or chrome, is deposited onto the surface of the tungsten carbide bushing.

This provides a highly resistant barrier against corrosion while maintaining the structural integrity of the bushing.

3.1). Benefits:

Cost-effective compared to other coating methods

Provides good corrosion protection without adding significant bulk

Ideal for smaller components or parts requiring a precise coating thickness

Electroplating is commonly used in machinery and valves that are exposed to mildly corrosive environments.

4). Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) is a highly advanced process where a thin, uniform film of a corrosion-resistant material is deposited onto the tungsten carbide surface.

CVD is commonly used to create coatings like titanium carbide or boron carbide, which are highly resistant to both wear and corrosion.

4.1). Benefits:

Provides a very uniform and durable coating

Protects against a wide range of corrosive substances

Excellent for high-performance applications requiring high precision

CVD coatings are used in aerospace and high-temperature machinery where maximum protection is needed.

Choosing the Right Anti-Corrosion Treatment for Your Application

Choosing the appropriate anti-corrosion treatment for your tungsten carbide bushings depends on several factors, including the specific environment in which the bushings will operate.

Here’s a quick guide to help you choose the right treatment:

| Environment | Recommended Treatment | Pourquoi |

|---|---|---|

| Acidic or Alkaline Environments | TiN Coating | Provides excellent corrosion resistance |

| High-Temperature Environments | DLC Coating | Offers high thermal stability and wear resistance |

| Harsh Chemical Exposure | Chromium Coating | Resists chemical attack in aggressive environments |

| Abrasive Environments | Plasma Spray Coating | Durable and resistant to both wear and corrosion |

| Mild Corrosive Exposure | Electroplating | Cost-effective protection for light exposure |

Benefits of Anti-Corrosion Treatments for Tungsten Carbide Bushings

The key benefits of anti-corrosion treatments include:

1). Increased Longevity

By applying the right coating, the life of the tungsten carbide bushing can be significantly extended, even in the harshest environments. This results in fewer replacements and reduced maintenance costs.

2). Improved Performance

Anti-corrosion treatments enhance the performance of tungsten carbide bushings by improving résistance à l'usure, friction, and corrosion resistance, making them more reliable and efficient.

3). Cost-Effectiveness

Though anti-corrosion treatments may increase the upfront cost, they are highly cost-effective in the long run.

The reduction in maintenance, downtime, and replacement costs makes them a worthwhile investment for industries that rely on high-performance machinery.

Conclusion

Tungsten carbide bushings are essential components in many industrial applications, and protecting them from corrosion is key to ensuring long-term performance and reliability.

By using advanced anti-corrosion treatments such as coatings, plasma spraying, electroplating, and CVD, manufacturers can significantly enhance the durability of their bushings, reducing maintenance costs and downtime.

Choosing the right treatment for your specific application will ensure that your bushings operate at peak efficiency even in the harshest environments.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.