Le automobile industry is constantly evolving. Modern vehicles demand higher performance, lighter materials, and longer-lasting components to stay competitive.

Every part — from the engine to the transmission — must operate smoothly and reliably for thousands of hours.

This pressure to improve efficiency and reduce maintenance has made bagues en carbure de tungstène an essential part of many automotive systems.

Known for their exceptional résistance à l'usure, high strength, and thermal stability, these bushings are now widely used in engines, gearboxes, turbochargers, and even electric vehicle (EV) components.

This article explores how tungsten carbide bushings are applied across the automotive industry, what benefits they provide, and why they are becoming a standard material choice for advanced mobility systems.

Why Automotive Engineers Choose Tungsten Carbide

The automotive sector operates under extreme design and cost constraints.

Components must last longer, perform better, and withstand severe wear, all while being compact and lightweight.

Tungsten carbide bushings meet these challenges thanks to their unique material characteristics.

Propriétés clés :

Dureté up to 92 HRA for superior wear resistance.

High compressive strength (above 4000 MPa).

Excellent thermal stability for engine and gearbox environments.

Low coefficient of friction, even with minimal lubrication.

Corrosion resistance against fuel, oil, and coolants.

These properties help improve reliability, reduce downtime, and extend vehicle component life — especially in demanding applications.

Comparison with Conventional Bushing Materials

| Matériel | Résistance à l'usure | Stabilité thermique | Friction Behavior | Durée de vie |

|---|---|---|---|---|

| Bronze | Faible | Modéré | Average | Court |

| Acier | Modéré | Haut | Bien | Moyen |

| Carbure de tungstène | Excellent | Excellent | Low Friction | Très long |

bagues en carbure de tungstène outperform traditional materials in every major category that affects durability and efficiency — which is why they are becoming the preferred choice in modern automotive design.

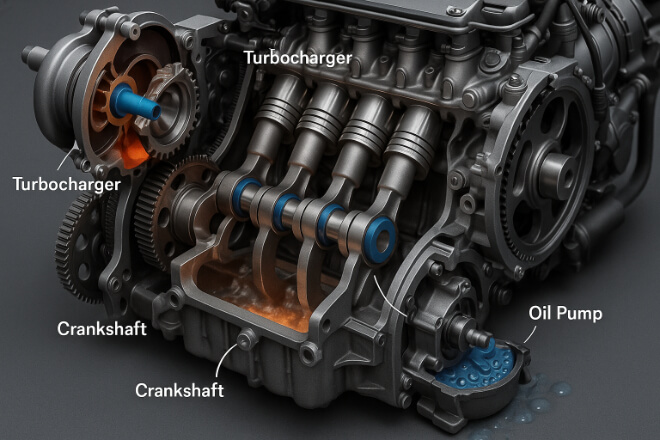

Engine and Powertrain Applications

Automotive engines generate enormous friction between moving parts such as connecting rods, crankshafts, and camshafts.

Bushings in these areas must resist wear under both high pressure and heat.

Common uses include:

Turbocharger bearings — to handle extreme rotational speeds and temperatures.

Camshaft and crankshaft supports — for precision rotation under heavy loads.

Transmission shafts — to reduce metal-to-metal contact and improve torque transfer.

Oil pump bushings — for high reliability under varying lubrication conditions.

Tungsten carbide bushings in these systems reduce wear, maintain clearances, and ensure smooth operation for thousands of hours.

Suspension and Steering Components

| Composant | Operating Stress | Benefit of Tungsten Carbide Bushing |

|---|---|---|

| Steering Knuckle | High vibration and dust exposure | Improves wear resistance and stability |

| Shock Absorber Mount | Constant compression and rebound motion | Reduces deformation and maintains alignment |

| Control Arm | High impact and environmental exposure | Extends service life and prevents corrosion |

In these applications, tungsten carbide bushings ensure precision movement and noise reduction, even in dusty, muddy, or high-load driving conditions.

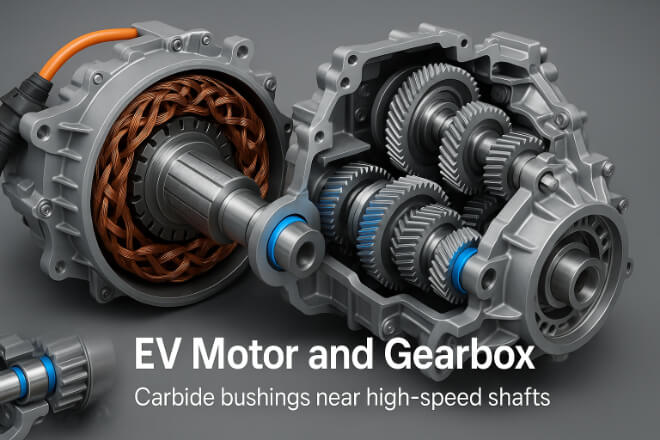

Role in Electric Vehicles (EVs)

Electric vehicles place new demands on mechanical systems.

Though EVs have fewer moving parts, they still rely on high-speed rotating shafts and precision couplings that require durable bushings.

Key EV Applications:

Electric motor rotors — for smooth rotation under high RPM.

Cooling pumps — exposed to thermal cycling and conductive fluids.

Gear reduction systems — handling torque transfer between motor and wheels.

Battery coolant systems — resisting corrosion from specialized fluids.

Tungsten carbide bushings maintain their structure and dimensional accuracy under the constant temperature fluctuations found in EV powertrains.

Manufacturing and Testing Equipment

| Machine Type | Wear Condition | Function of Bushing |

|---|---|---|

| CNC Machining Centers | High-speed spindle wear | Provides stability and precision movement |

| Robotic Assembly Tools | Continuous cycling and friction | Ensures alignment and repeatable motion |

| Quality Testing Fixtures | Pressure and fatigue exposure | Maintains precision fit during long testing cycles |

Automotive plants also use tungsten carbide bushings in assembly lines, robotic joints, and precision tools, where repeatability and minimal wear are critical for consistent production quality.

Advantages for Automotive Manufacturers

Using tungsten carbide bushings delivers multiple benefits across both production and vehicle operation:

Reduced maintenance costs and longer component lifespan.

Improved heat and résistance à l'usure under harsh conditions.

Better dimensional control and tight tolerances.

Stable performance in oil, fuel, and coolant exposure.

Enhanced efficiency in high-speed or high-load parts.

By extending part life and improving system reliability, these bushings also support sustainability goals through fewer replacements and less downtime.

Considérations relatives aux coûts et au retour sur investissement

While tungsten carbide bushings have a higher initial cost compared to bronze or steel, their long service life and reduced maintenance often lead to a lower total cost of ownership.

| Matériel | Coût initial | Durée de vie | Maintenance Frequency | Overall ROI |

|---|---|---|---|---|

| Acier | Faible | Moyen | Fréquent | Modéré |

| Bronze | Faible | Court | Fréquent | Faible |

| Carbure de tungstène | Haut | Très long | Rare | Haut |

For automotive OEMs focused on reducing warranty claims and improving reliability, the ROI of tungsten carbide components is clear and measurable.

Conclusion

In an industry where durability, performance, and efficiency are everything, tungsten carbide bushings provide a proven solution.

They outperform traditional materials across all key areas — wear resistance, heat tolerance, and long-term reliability — making them essential for both internal combustion and electric vehicles.

For automotive manufacturers, using tungsten carbide bushings means fewer breakdowns, longer part life, and greater customer satisfaction — a powerful combination in the race for excellence.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.