Slurry applications in industries like exploitation minière, wastewater treatment, and chemical processing require equipment that can handle abrasive, corrosive, and high-pressure conditions.

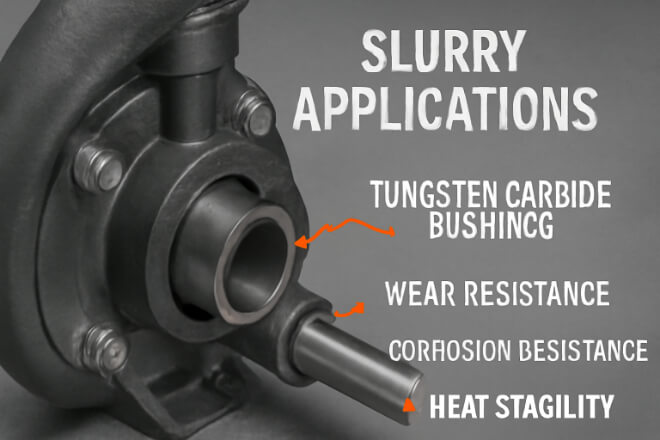

bagues en carbure de tungstène are an excellent choice for these environments due to their résistance à l'usure, dureté, and ability to withstand corrosion.

This guide explores the best materials for tungsten carbide bushings in slurry applications, helping you choose the right one for optimal performance and durability.

Why Tungsten Carbide Bushings Are Ideal for Slurry Applications

Tungsten carbide is one of the hardest materials available, making it perfect for handling abrasive slurries.

The material’s resistance to wear, corrosion, and high temperatures allows it to perform effectively in challenging environments where traditional materials would fail quickly.

Here are a few key reasons why tungsten carbide bushings excel in slurry applications:

Haut Résistance à l'usure: Tungsten carbide can withstand the abrasive forces typically found in slurry environments, reducing the frequency of replacements and extending equipment life.

Résistance à la corrosion: Slurries often contain corrosive substances like acids, salts, and chemicals. Tungsten carbide’s corrosion resistance helps prevent degradation in these environments.

Résistance à la chaleur: Tungsten carbide maintains its strength at high temperatures, ensuring consistent performance even in heated slurry applications.

Stabilité dimensionnelle: Tungsten carbide maintains its shape and size over time, even under extreme conditions, which is critical for precision in slurry pumps and valves.

Key Materials for Tungsten Carbide Bushings in Slurry Applications

Not all tungsten carbide materials are the same. The binder type, grain size, and specific formulation of tungsten carbide can all influence its performance in slurry applications.

The following are the best materials for tungsten carbide bushings in these environments:

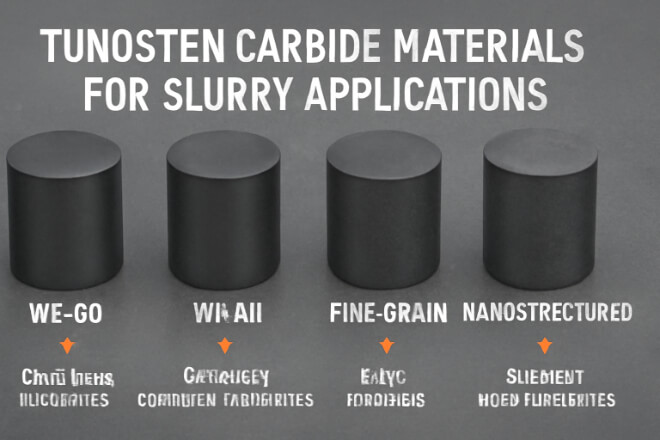

1). WC-Co (Cobalt Binder Tungsten Carbide)

WC-Co is one of the most common tungsten carbide formulations, offering excellent wear resistance and toughness.

The addition of cobalt as a binder enhances the material’s impact resistance, making it ideal for slurry applications that involve both abrasive particles and high-impact forces.

1.1). Advantages:

Haut résistance à l'usure

Good toughness and impact strength

Reliable performance in abrasive slurries

1.2). Best For:

High-abrasion slurry environments, mining, and pump applications.

2). WC-Ni (Nickel Binder Tungsten Carbide)

WC-Ni is a tungsten carbide formulation that uses nickel as a binder instead of cobalt.

This material is especially beneficial for applications where corrosion resistance is crucial.

Nickel provides better resistance to chemicals and corrosion, making WC-Ni ideal for slurry environments that contain aggressive or corrosive substances.

2.1). Advantages:

Excellent résistance à la corrosion

Good for chemically aggressive slurries

Haute résistance à l'usure

2.2). Best For:

Slurries with a high chemical or acidic content, wastewater treatment, and chemical processing.

3). Fine-Grain Tungsten Carbide

Fine-grain tungsten carbide is made by reducing the particle size of the tungsten carbide powder during production.

This results in a denser, more uniform material with improved hardness and wear resistance.

Fine-grain tungsten carbide is highly effective in slurry applications where the slurries contain small, abrasive particles that would otherwise wear out standard materials quickly.

3.1). Advantages:

Increased dureté et résistance à l'usure

Meilleure finition de surface

Enhanced dimensional stability

3.2). Best For:

High-abrasion slurry applications with fine particles, mining, and slurry transport.

4). Nanostructured Tungsten Carbide

Nanostructured tungsten carbide is an advanced material that incorporates very fine tungsten carbide grains to create a material with superior toughness and wear resistance.

It offers the combined benefits of high hardness and impact resistance, making it ideal for slurry applications that involve both fine and coarse particles.

4.1). Advantages:

Superior hardness and dureté

Excellent wear and impact resistance

High thermal stability

4.2). Best For:

High-performance slurry applications with mixed particle sizes, including mining and dredging.

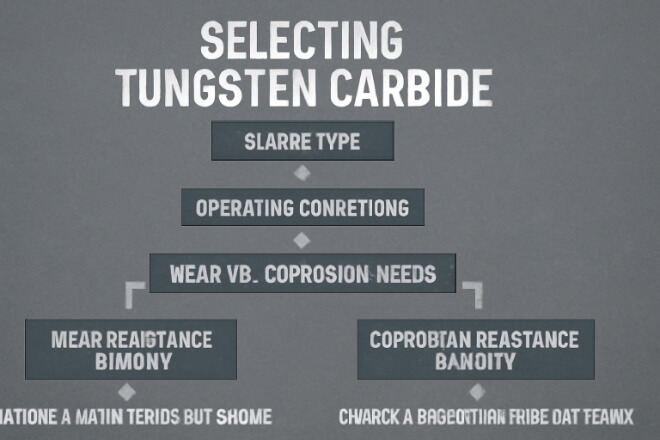

How to Choose the Right Tungsten Carbide Material for Your Slurry Application

Choosing the right material for tungsten carbide bushings in slurry applications depends on several factors, including the specific conditions of the slurry and the equipment being used.

Here are the key considerations when selecting the best tungsten carbide material:

1). Type of Slurry

Slurries can vary widely in their composition, from fine particles in water to coarse solids in acidic liquids. Consider the type of slurry your equipment will be exposed to:

For abrasive slurries with fine particles, fine-grain tungsten carbide or nanostructured tungsten carbide is ideal.

For chemically aggressive slurries, WC-Ni offers superior corrosion resistance.

2). Operating Conditions

Consider the temperature and pressure at which the slurry will be pumped or processed.

Some tungsten carbide materials perform better at high temperatures or under high-pressure conditions:

WC-Co performs well under high-impact, abrasive conditions.

WC-Ni is better for environments that involve chemical exposure but may not be as effective under extreme temperatures as WC-Co.

3). Wear vs. Résistance à la corrosion

If your slurry is particularly abrasive but not chemically aggressive, WC-Co may be the best option due to its high wear resistance and toughness.

However, for chemically aggressive slurries, WC-Ni will provide better corrosion protection, even if its wear resistance is slightly lower.

4). Cost Considerations

While WC-Co is generally less expensive than WC-Ni or nanostructured tungsten carbide, the right material choice should balance performance and cost.

Consider the operational life and maintenance savings when making a decision.

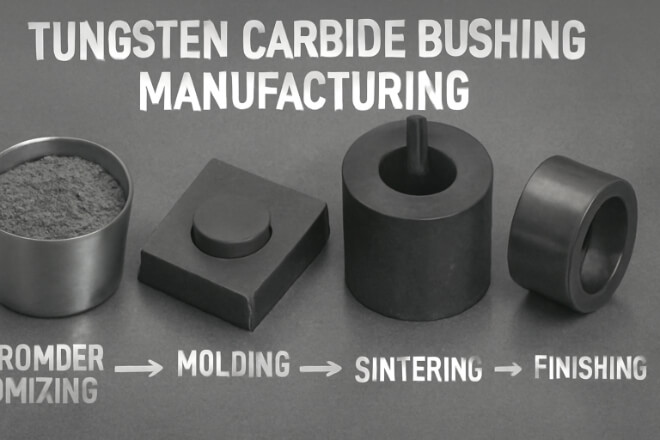

Manufacturing Process for Tungsten Carbide Bushings

Tungsten carbide bushings are manufactured through a process that involves several key steps:

Powder Mixing: Tungsten carbide powder is mixed with the binder material (such as cobalt or nickel) to form a slurry.

Molding: The slurry is pressed into molds to form the bushing shape.

Sintering: The molded bushings are sintered at high temperatures to fuse the material.

Machining and Finishing: The sintered bushings are precision-machined to achieve the required dimensions and surface finish.

This manufacturing process ensures that the tungsten carbide bushings are durable and fit the specifications required for slurry applications.

Conclusion

Tungsten carbide bushings are essential for ensuring the performance and longevity of equipment used in slurry applications.

By choosing the right material—whether it’s WC-Co, WC-Ni, fine-grain tungsten carbide, or nanostructured tungsten carbide—industries can improve wear resistance, reduce maintenance costs, and extend the lifespan of their pumps and valves.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.