Bagues d'étanchéité en carbure de tungstène are widely used in pumps, compressors, turbines, and marine equipment.

Their strength, dureté, et résistance à la corrosion make them a top choice for mechanical seals in industries like pétrole et gaz, chemical processing, power generation, and marine systems.

However, even tungsten carbide seals can fail if used incorrectly or in harsh conditions without proper care.

Understanding common failure modes helps decision-makers reduce downtime, cut costs, and improve safety.

Why Seal Ring Failures Are Costly

Temps d'arrêt imprévus → Production halts, leading to lost revenue.

Expensive repairs → Pumps or compressors may need replacement parts.

Environmental risks → Leaks can cause spills or contamination.

Safety hazards → High-pressure leaks threaten workers and equipment.

Higher life cycle costs → Frequent failures increase long-term expenses.

Common Failure Modes of Tungsten Carbide Seal Rings

1). Wear from Abrasive Fluids

Cause: Slurry, sand, or debris in fluids grinds against the seal surface.

Effect: Rapid erosion and reduced sealing efficiency.

Prevention: Use proper filtration, select a harder grade, or use protective coatings.

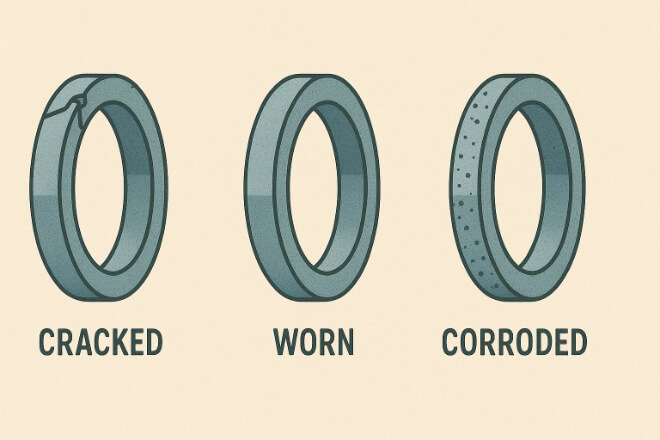

2). Thermal Shock or Cracking

Cause: Rapid temperature changes between hot and cold fluids.

Effect: Cracks develop, leading to leaks.

Prevention: Allow gradual temperature transitions and ensure correct thermal expansion allowances.

3). Corrosion Damage

Cause: Aggressive chemicals or seawater attacking the binder material.

Effect: Surface pitting, loss of material, and leaks.

Prevention: Choose nickel-bonded tungsten carbide for chemical-rich fluids.

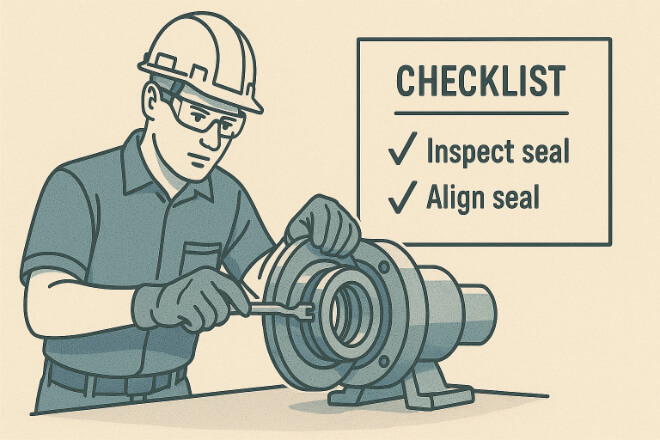

4). Poor Installation or Misalignment

Cause: Scratches, uneven torque, or incorrect fitting during assembly.

Effect: Uneven wear, leaks, and premature failure.

Prevention: Train technicians, follow manufacturer guidelines, and inspect installation surfaces.

5). Vibration and Mechanical Shock

Cause: Pumps or compressors operating under high vibration or pressure changes.

Effect: Chipping or breaking of seal edges.

Prevention: Use cobalt-bonded tungsten carbide for impact resistance and maintain equipment balance.

6). Lubrication Failure

Cause: Insufficient lubrication or dry running.

Effect: Overheating and surface damage.

Prevention: Maintain proper fluid levels and check lubrication systems regularly.

Advantages of Tungsten Carbide Over Other Materials

| Fonctionnalité | Carbure de tungstène | Céramique | Acier |

|---|---|---|---|

| Résistance à l'usure | Excellent pour les abrasifs | Modéré | Pauvre |

| Résistance à la corrosion | Haute (teneurs en nickel) | Très bien | Faible |

| Dureté | Haut, résiste aux chocs | Faible, cassant | Modéré |

| Stabilité thermique | Excellent at high/low temp | Bien | Modéré |

| Durée de vie | Longue durée | Modéré | Court |

Best Practices to Avoid Failures

Match material to environment → Nickel-bonded for chemicals, cobalt-bonded for shock.

Control operating conditions → Prevent dry running, extreme vibration, and rapid temperature changes.

Inspectez régulièrement les joints → Spot early signs of wear or cracking.

Train staff → Proper installation and handling reduce damage.

Partner with reliable suppliers → Ensure correct specifications and quality assurance.

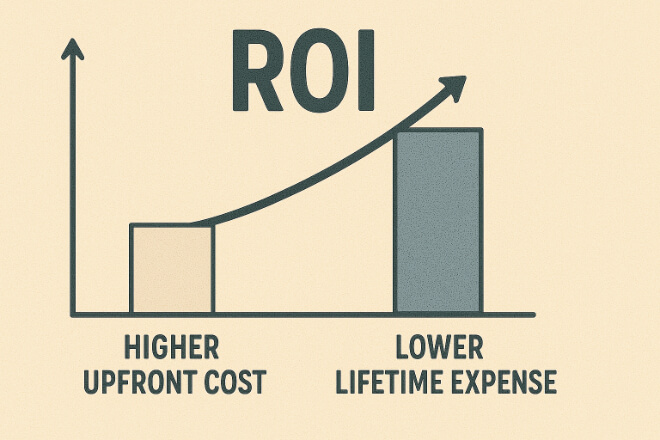

Considérations relatives aux coûts et au retour sur investissement

While tungsten carbide seal rings cost more initially:

They reduce downtime by lasting longer.

They cut maintenance costs with fewer replacements.

They protect equipment, preventing expensive failures.

Over time, they provide better ROI than cheaper alternatives.

Avantages environnementaux et de sécurité

Prévention des fuites → Protects ecosystems and workers.

Matériau recyclable → Worn rings can be recovered and reused.

Improved efficiency → Leak-free systems save energy and resources.

Points clés à retenir pour les décideurs

Most tungsten carbide failures stem from abrasion, thermal shock, corrosion, or misalignment.

Proper selection, installation, and maintenance prevent costly downtime.

Investing in quality materials and training yields long-term savings.

Tungsten carbide seal rings are the best choice for demanding industrial environments.

Conclusion

Understanding failure modes allows decision-makers to use tungsten carbide seal rings effectively.

By selecting the right grade, maintaining operating conditions, and following best practices, industries can achieve leak-free, reliable performance.

For critical systems in oil, gas, power, chemical, or marine operations, tungsten carbide is a smart investment that ensures safety, efficiency, and sustainability.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.