In mechanical seal manufacturing and maintenance, carbide face lapping is a crucial finishing process. Proper lapping ensures surface flatness, low roughness (Ra), and tight sealing performance.

Three key factors—conditioning rings, lapping plate selection, and slurry control—determine the quality and repeatability of the finish.

This guide explains how these elements affect carbide face lapping and provides best practices for decision-makers aiming to improve seal performance and reduce leakage risks.

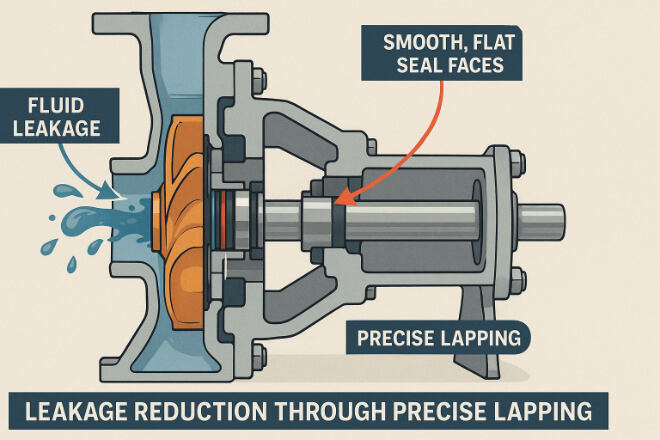

Why Carbide Face Lapping Quality Matters

Leakage control: Flat, smooth faces reduce fluid escape.

Seal reliability: Proper lapping prevents premature wear and failures.

Energy efficiency: Well-finished faces reduce friction and heat generation.

Long-term cost savings: Improved surface quality extends seal life and reduces maintenance.

Conditioning Rings: Their Role and Best Practices

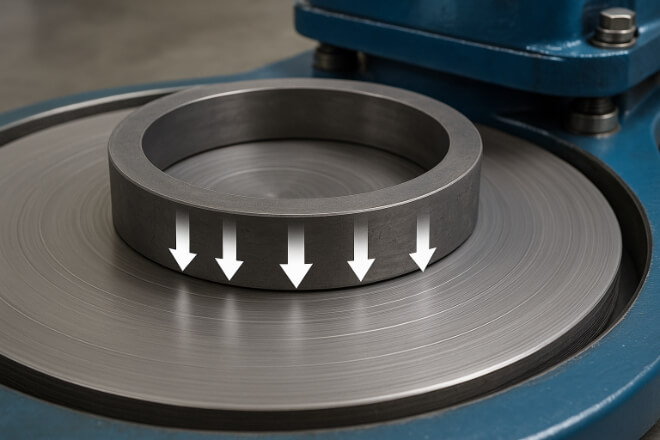

Conditioning rings are used to maintain the flatness of the lapping plate and ensure even material removal.

1). Functions of Conditioning Rings

Plate conditioning: Keeps the lapping plate flat during use.

Workpiece positioning: Holds carbide faces in place for even abrasion.

Wear distribution: Spreads contact pressure to prevent plate distortion.

2). Best Practices

Choose proper size and material: Match ring dureté to the carbide and plate type.

Apply even pressure: Uneven force can create plate taper or warping.

Inspect frequently: Worn rings can compromise flatness and cause uneven finishes.

Lapping Plate Selection for Carbide Faces

The lapping plate is the surface against which the carbide faces are finished. Choosing the right plate impacts the speed, quality, and consistency of the process.

1). Plate Material Options

Cast iron plates: Versatile and commonly used for tungsten carbide.

Copper plates: Suitable for intermediate polishing stages.

Composite plates: Designed for controlled removal and reduced scratching.

2). Plate Texture

Grooved plates: Allow slurry distribution and prevent hydroplaning.

Flat plates: Best for final stages to achieve perfect flatness.

3). Selection Tips

Match plate dureté to the carbide grade and desired Ra.

Use flatness gauges to verify plate condition before use.

Replace or recondition plates showing excessive wear or grooves.

Slurry Control in Lapping Operations

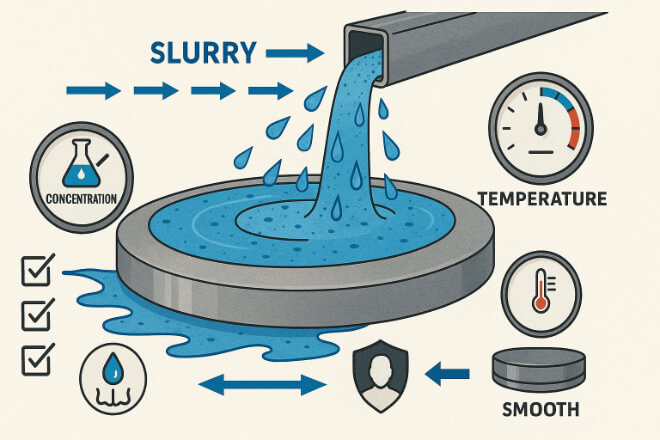

The lapping slurry—a mixture of abrasive particles and fluid—removes material from the carbide surface. Proper slurry control is essential for quality finishes.

1). Importance of Slurry Control

Consistency: Uniform slurry concentration ensures even removal.

Surface finish quality: Correct slurry size prevents scratches or excessive roughness.

Cost efficiency: Proper usage reduces abrasive waste.

2). Best Practices

Select the right abrasive: Diamond slurry is preferred for tungsten carbide.

Monitor concentration: Too much abrasive can scratch surfaces; too little slows removal.

Filter regularly: Remove debris and worn particles to maintain efficiency.

Control temperature: Excess heat can cause distortion or uneven wear.

Comparison Table: Conditioning, Plates, and Slurry Control

| Facteur | Primary Role | Best Practices |

|---|---|---|

| Conditioning Rings | Maintain plate flatness and position workpieces | Match hardness, apply even pressure, inspect regularly |

| Plate Selection | Provide proper surface hardness and texture | Use cast iron for carbide, check flatness before use |

| Slurry Control | Remove material efficiently and evenly | Monitor concentration, filter debris, control temperature |

Common Issues and Solutions

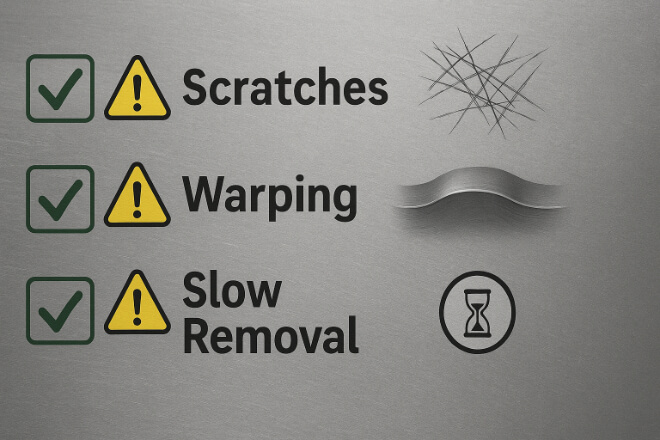

Uneven wear on seal faces: Check conditioning ring pressure and plate flatness.

Scratches or surface defects: Use clean slurry and proper particle size.

Slow removal rates: Verify slurry concentration or switch to a more suitable abrasive.

Plate warping: Regularly recondition plates and use appropriate support fixtures.

Industry Applications That Depend on Quality Lapping

Petrochemical pumps: Require tight sealing to prevent hazardous leaks.

Marine pumps and compressors: Need reliable seals under varying loads.

Power generation equipment: High-pressure systems demand precise finishes.

Pharmaceutical mixers: Ultra-flat faces prevent contamination and product loss.

Maintenance Tips for Long-Term Performance

Store plates and rings in clean, dry areas to avoid contamination.

Replace conditioning rings before they become too worn.

Clean lapping machines thoroughly after use to prevent abrasive buildup.

Schedule routine inspections of slurry delivery systems and filters.

Considérations relatives aux coûts et au retour sur investissement

Initial cost: High-quality plates and abrasives may cost more upfront.

Savings: Better finishes reduce leakage, downtime, and replacement costs.

ROI: Proper lapping processes improve seal reliability and extend equipment life.

Conclusion

Conditioning rings, plate selection, and slurry control are the three pillars of carbide face lapping best practices.

By managing these factors effectively, decision-makers can achieve precise Ra and flatness, ensuring longer-lasting seals, lower leakage rates, and better overall performance.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.