In pumps, compressors, and turbines, seal rings are small but vital parts. They stop leaks, protect equipment, and keep systems safe.

But not all seal materials can survive the same harsh conditions. For industries dealing with chemicals, seawater, or high temperatures, the best choice is often the bague d'étanchéité en carbure de tungstène.

Tungsten carbide is famous for its dureté, but two of its most valuable properties are corrosion resistance and heat resistance.

These features make it suitable for industries such as pétrole et gaz, chemical processing, marine systems, and power plants.

This article explains how tungsten carbide seal rings resist corrosion and heat, why these properties matter, and what decision-makers should consider when choosing them.

Que sont les bagues d’étanchéité en carbure de tungstène ?

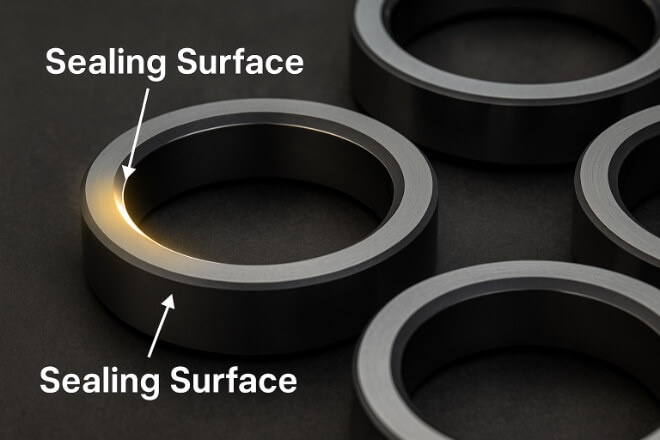

Tungsten carbide seal rings are mechanical sealing parts made by pressing and sintering poudre de carbure de tungstène with a binder (usually cobalt or nickel).

They are used where fluids or gases must stay inside pumps, mixers, or compressors without leaking.

Unlike rubber or steel seals, tungsten carbide rings work even in extreme pressure, temperature, and chemical conditions.

Key features include:

Dureté close to diamond

Longue durée de vie

Resistance to wear, corrosion, and heat

Stable performance in harsh environments

Why Corrosion Resistance Matters

In many industries, seal rings are in direct contact with liquids and gases. If the material corrodes, leaks and failures follow quickly.

Main risks of corrosion:

Surface pitting weakens seals

Leaks lead to downtime and safety hazards

More frequent replacement increases cost

Tungsten carbide seal rings, especially those with nickel binder, provide strong corrosion protection. They can resist acids, seawater, and many chemical solutions.

Corrosion Resistance of Tungsten Carbide Seal Rings

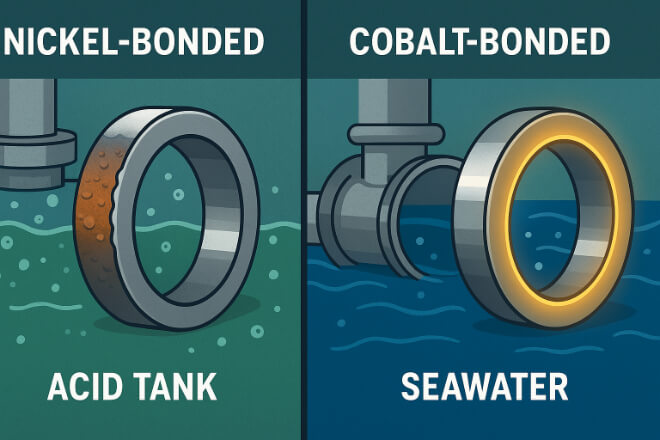

1). Nickel-Bonded Tungsten Carbide

Excellent resistance to acids and seawater

Best choice for chemical plants and marine pumps

2). Cobalt-Bonded Tungsten Carbide

Tougher but slightly less résistant à la corrosion

Often used in oilfield and mining applications

3). Benefits for Industry

Lower risk of chemical damage

Longer seal life in aggressive environments

Safer operations in critical plants

Why Heat Resistance Matters

Many machines run at high speeds or handle hot fluids. Seal rings that cannot handle heat will lose strength, deform, or fail.

Problems caused by poor heat resistance:

Cracking under thermal stress

Perte de dureté at high temperature

System shutdowns or accidents

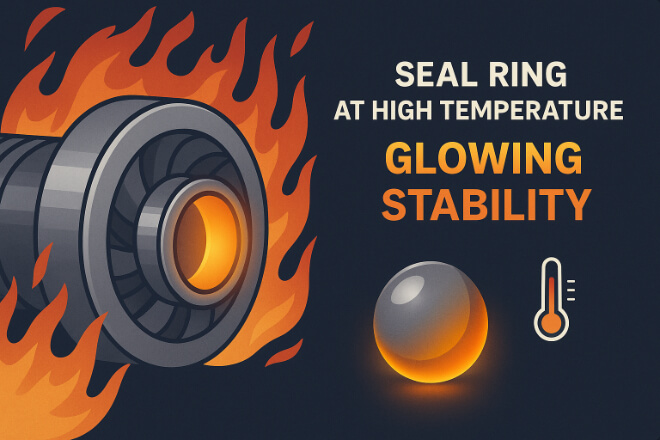

Tungsten carbide has high thermal stability, meaning it keeps its hardness and strength even in hot environments.

Heat Resistance of Tungsten Carbide Seal Rings

1). High Temperature Capability

Withstands temperatures up to several hundred degrees Celsius

Maintains sealing ability even in turbines and refineries

2). Thermal Shock Resistance

Resists cracking when temperatures change suddenly

Safer for pumps and compressors exposed to varying conditions

3). Benefits for Industry

Reliable sealing under hot conditions

Reduced maintenance in power and energy plants

Longer service life compared with steel or ceramic rings

Corrosion and Heat Resistance Working Together

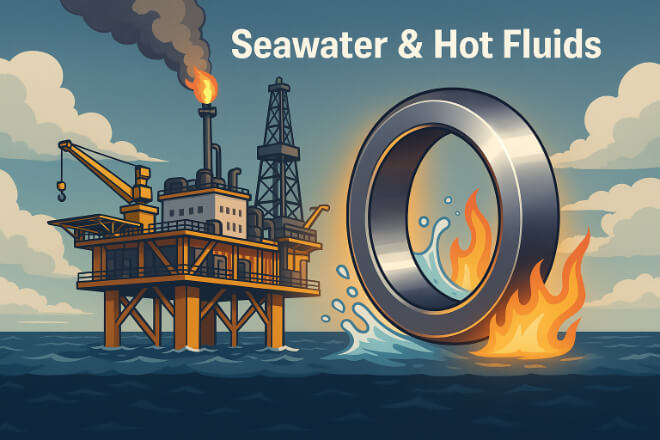

The real strength of tungsten carbide seal rings is their ability to handle both chemical attack and high temperature at the same time.

Par exemple:

In offshore oil rigs, they resist both seawater corrosion and hot drilling fluids.

In chemical refineries, they withstand hot acids and solvents.

In power plants, they survive high-pressure steam without losing hardness.

This combination makes tungsten carbide one of the most balanced choices for critical industries.

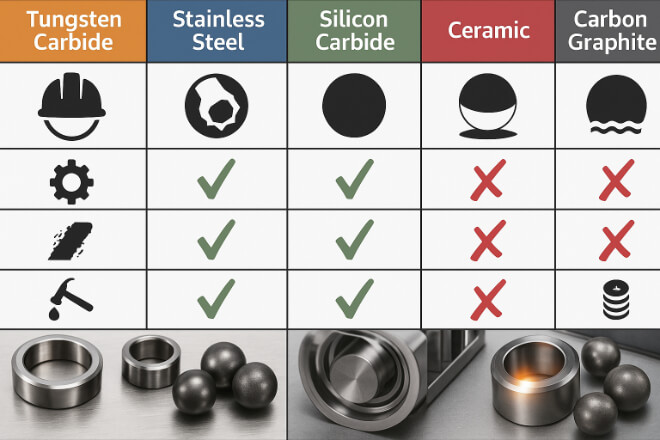

Comparaison avec d'autres matériaux

Stainless Steel: Affordable but weak against acids and high heat.

Silicon Carbide: Good against corrosion but more brittle under shock.

Ceramics: High heat resistance but prone to cracking.

Carbon Graphite: Self-lubricating but lacks strength.

Tungsten carbide provides a better balance of strength, corrosion resistance, and heat stability, making it more reliable in demanding operations.

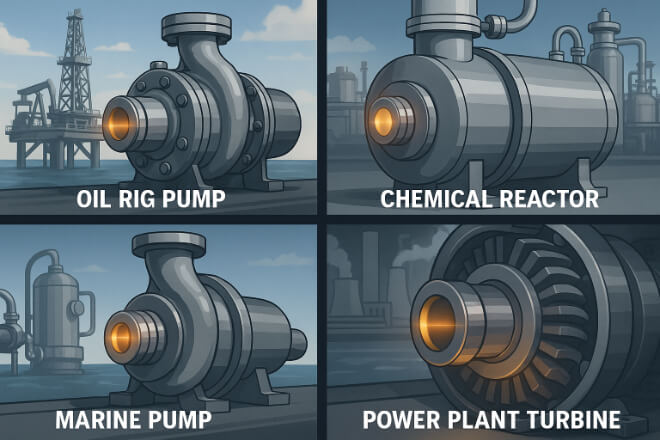

Applications That Need Corrosion and Heat Resistance

1). Pétrole et gaz Industrie

Seal rings in pumps and compressors face hot, abrasive, and corrosive drilling fluids. Tungsten carbide performs reliably.

2). Usines chimiques

Protects pumps and mixers from strong acids and solvents while resisting high heat.

3). Marine Industry

Resists seawater corrosion and works in offshore pumps.

4). Production d'électricité

Handles high-pressure steam in turbines and energy systems.

How to Choose the Right Tungsten Carbide Seal Ring

Decision-makers should check:

Binder Type – Nickel for corrosion, cobalt for dureté.

Operating Temperature – Match ring grade to system conditions.

Fluid Type – Acidic, seawater, or abrasive fluids need stronger resistance.

Supplier Quality – Ensure ISO standards and reliable testing.

Best Practices for Use

Install rings with proper alignment

Use lubrication if recommended

Inspect for surface cracks or wear

Replace before total failure

Keep spare parts in stock for critical equipment

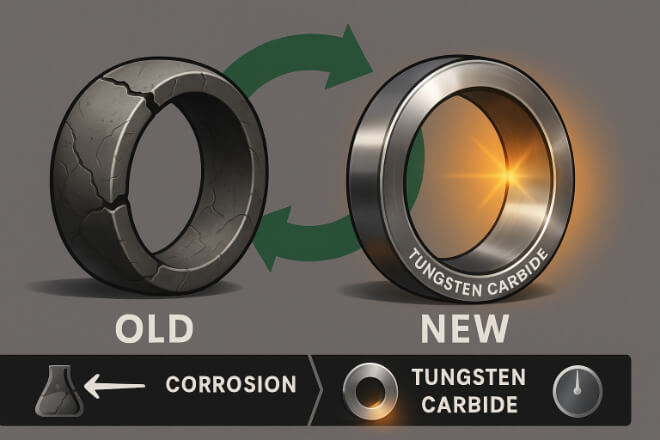

Entretien et remplacement

Even with high corrosion and heat resistance, tungsten carbide seal rings require regular checks.

Inspection Frequency: Every 2–4 weeks in critical plants

Warning Signs: Leaks, noise, or visible surface damage

Replacement: Always use the same grade and size

Recycling: Worn tungsten carbide can be recycled to save cost

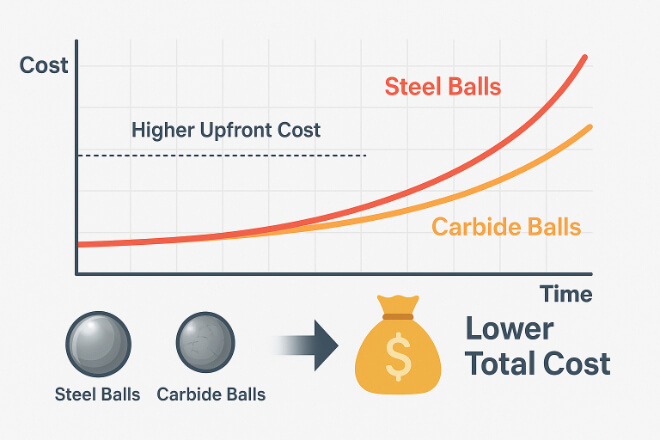

Cost and Business Value

Though tungsten carbide seal rings cost more upfront than steel, they offer:

5–10x longer lifespan

Reduced downtime from fewer failures

Safer operations under extreme conditions

Stronger return on investment

For decision-makers, these benefits outweigh the higher purchase price.

Exemples de cas

1). Offshore Oil Rig

Nickel-bonded tungsten carbide rings survived both seawater and hot drilling mud, lasting twice as long as previous seals.

2). Chemical Processing Plant

Seal rings resisted acid attack and high heat, reducing replacement cycles by 50%.

3). Power Plant Turbines

Seal rings stayed stable in high-temperature steam, cutting downtime and repair costs.

Comment se procurer des joints d'étanchéité en carbure de tungstène

When sourcing, companies should:

Select suppliers with experience in harsh applications

Verify ISO and industry certifications

Confirm stock availability for fast delivery

Ask for technical support and customization options

Conclusion

Corrosion and heat resistance are what make tungsten carbide seal rings a smart choice for demanding industries.

They last longer, handle harsh chemicals, and stay strong at high temperatures.

For oil & gas, chemical, marine, and energy sectors, tungsten carbide seal rings are an investment in safety, reliability, and cost efficiency.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.