Qu'est-ce que la résistance à la corrosion ?

La résistance à la corrosion désigne la capacité d'un matériau à résister à la dégradation chimique causée par ses interactions avec son environnement, comme l'humidité, les acides, les alcalis, les sels ou les gaz. La corrosion entraîne généralement oxydation, piqûres, érosion de surface et affaiblissement éventuel de la structure du matériau.

Les matériaux à haute résistance à la corrosion conservent leur intégrité mécanique, leur stabilité dimensionnelle et leur finition de surface même en cas d'exposition chimique agressive.

Pourquoi la résistance à la corrosion est-elle importante ?

Dans de nombreuses applications industrielles, les outils et les composants fonctionnent dans des environnements corrosifs tels que :

Conditions d'eau salée ou marine

Fluides de procédé acides ou alcalins

Installations industrielles à forte humidité

Pétrole, gaz, ou raffineries chimiques

La corrosion peut compromettre la résistance de l’outil, réduire la précision, accélérer l’usure et même entraîner une défaillance inattendue, entraînant des temps d’arrêt et une maintenance coûteux.

Carbure de tungstène et résistance à la corrosion

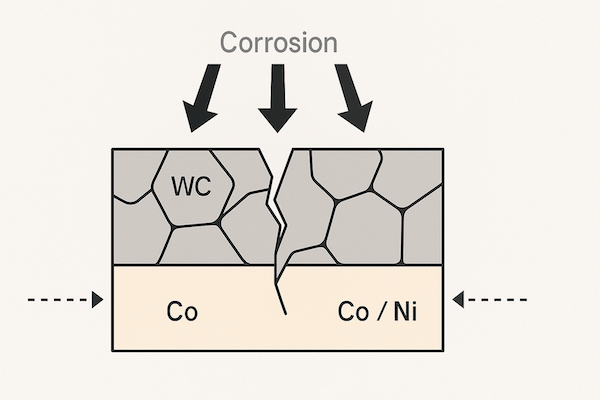

Le carbure de tungstène (WC) est un composé céramique dur offrant une excellente résistance à l'usure et à l'abrasion. Cependant, lorsqu'il est utilisé sous forme de carbure cémenté (WC lié à un liant métallique comme le cobalt ou le nickel), sa résistance à la corrosion dépend fortement de la phase du liant.

Influence du liant :

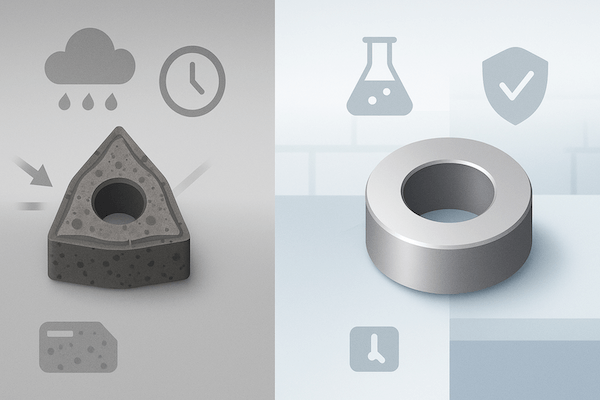

Carbures liés au cobalt (WC-Co) : sensibles à la corrosion, en particulier dans les environnements acides ou riches en chlorures.

Carbures liés au nickel (WC-Ni) : offrent une meilleure résistance à la corrosion par rapport au cobalt, ce qui les rend mieux adaptés à l'exposition marine ou chimique.

En général, les grains de carbure de tungstène pur sont chimiquement inertes, mais la phase liante métallique est vulnérable à la corrosion, ce qui peut entraîner une lixiviation du liant et un détachement des grains au fil du temps.

Comment la corrosion affecte les outils en carbure cémenté

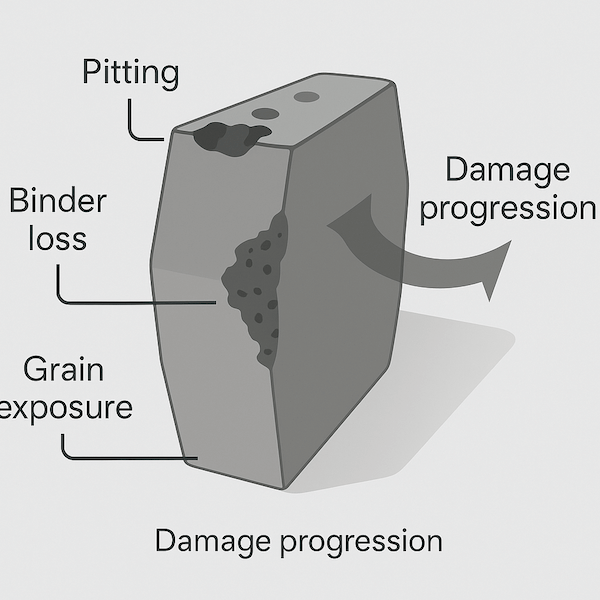

La corrosion des outils en carbure de tungstène peut entraîner :

Perte de phase liante, affaiblissant la structure

Piqûres et érosion de surface, réduisant la précision

Attaque des joints de grains, conduisant à des microfissures

Usure accélérée et durée de vie de l'outil plus courte

Ceci est particulièrement critique dans les outils exposés à la fois aux attaques chimiques et aux contraintes mécaniques, tels que les buses à boue, les sièges de soupape, les pièces de champs pétrolifères et les outils de formage dans des environnements humides ou acides.

Amélioration de la résistance à la corrosion du carbure de tungstène

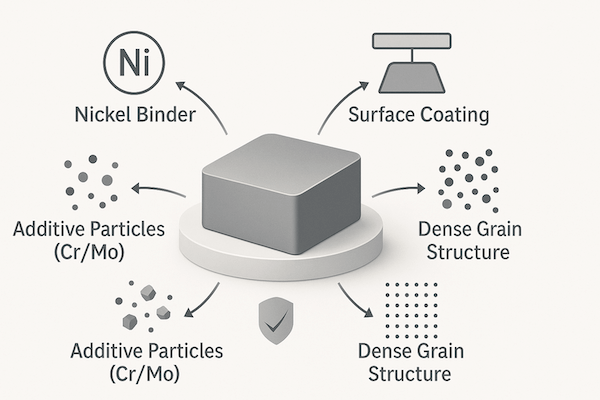

Pour améliorer les performances en matière de corrosion, les fabricants peuvent :

▸ Utiliser des liants résistants à la corrosion :

Alliages à base de nickel ou de Ni au lieu de cobalt pour les environnements chimiquement agressifs.

▸ Appliquer des revêtements protecteurs :

Tels que les revêtements TiN, TiCN ou CrN qui forment une barrière chimiquement stable.

▸ Ajouter des inhibiteurs de corrosion :

Des oligo-éléments comme le Cr, le Mo ou le V peuvent être introduits pour améliorer la résistance.

▸ Optimiser la structure des grains de carbure :

Dense, uniforme microstructures réduire porosité et les points d’initiation des fissures.

Applications typiques nécessitant une résistance élevée à la corrosion

Les outils en carbure cémenté avec une résistance améliorée à la corrosion sont essentiels dans :

Industrie pétrolière et gazière – garnitures de soupapes, manchons de pompeet composants de contrôle de flux

Ingénierie marine – sous-marine outils de coupe et pièces d'usure

Traitement chimique – scellés, matrices et outils de mesure exposés aux acides/alcalis

Alimentaire et pharmaceutique – outils de qualité sanitaire nécessitant une stabilité à la corrosion

Pâtes et papiers – lames de coupe exposées à des environnements humides et chargés de produits chimiques

Dans ces applications, la résistance à la corrosion garantit la sécurité, la longévité et la précision.

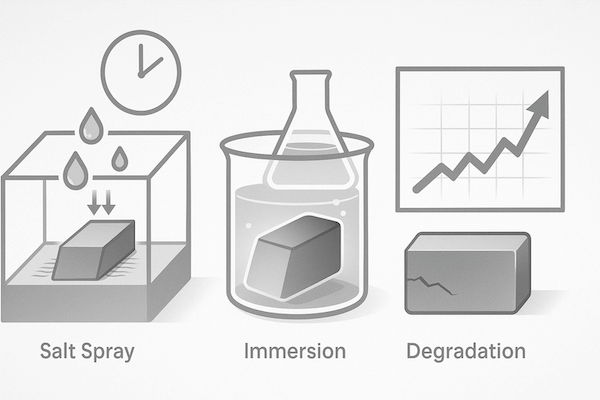

Test de résistance à la corrosion

La performance en matière de corrosion est souvent évaluée à travers :

Essai au brouillard salin (ASTM B117)

Spectroscopie d'impédance électrochimique (EIS)

Essais d'immersion dans des solutions acides/alcalines

Essais d'exposition sur le terrain dans des environnements d'utilisation finale

Ces méthodes permettent de quantifier la résistance d’une nuance ou d’un revêtement de carbure spécifique à la dégradation dans des conditions réalistes.

Conclusion

La résistance à la corrosion est un facteur de performance critique pour outils en carbure de tungstène Utilisé dans des environnements agressifs. Bien que le carbure cémenté soit très stable, la phase liante détermine souvent la résistance à la corrosion. En choisissant le bon liant, en appliquant des revêtements protecteurs et en optimisant la microstructure, les ingénieurs peuvent améliorer considérablement la durabilité et la stabilité chimique des composants en carbure cémenté, maximisant ainsi leur valeur et leur fiabilité dans les industries exigeantes.