As industries strive to reduce energy costs and minimize environmental impact, bagues en carbure de tungstène have become a key component in achieving these goals.

These high-performance bushings not only enhance the longevity of machinery but also offer significant energy savings.

In this blog, we’ll dive into how long-life tungsten carbide bushings can help industries run more efficiently while cutting down on energy consumption.

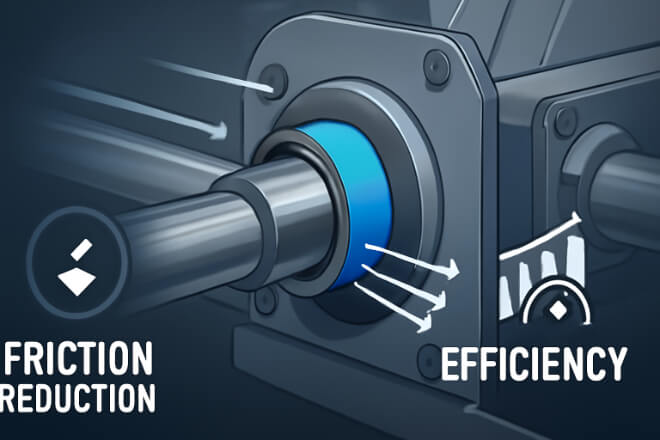

Advantage 1: Reduced Friction for Lower Energy Consumption

Tungsten carbide bushings are known for their exceptional dureté et résistance à l'usure, which translates to reduced friction between moving parts.

Friction is a major energy drain in machinery, as more energy is required to overcome resistance.

Tungsten carbide’s low friction properties mean machines run more smoothly with less effort, lowering the overall energy consumption.

When friction is reduced, machinery requires less power to maintain operation, which leads to energy savings.

In industries with continuous operations, such as manufacturing and mining, even a small reduction in friction can lead to substantial energy savings over time.

Example:

In a factory setting, a production line using tungsten carbide bushings can operate more efficiently, cutting down electricity costs by up to 15% compared to machines with standard steel bushings.

This not only saves money but also reduces the environmental impact of energy use.

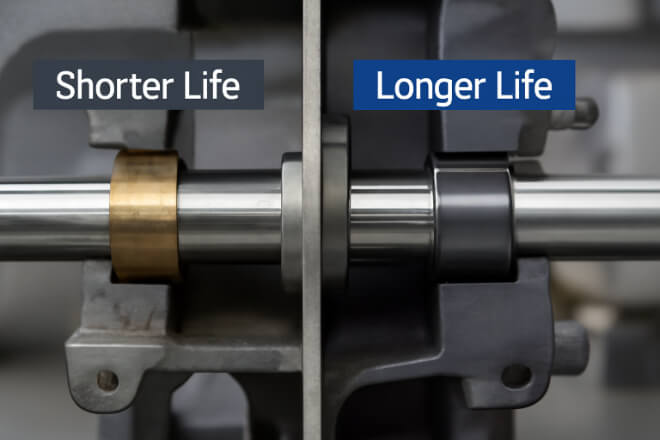

Advantage 2: Extended Equipment Life for Reduced Energy Loss

The longer machinery lasts without needing replacement parts, the less energy is wasted in the production and transportation of those parts.

bagues en carbure de tungstène are incredibly durable and resistant to wear, meaning they last significantly longer than traditional bushings.

This extended lifespan directly translates to reduced downtime and fewer interruptions to the production process.

When components like bushings are replaced frequently, downtime increases, and machines lose efficiency.

Tungsten carbide bushings, however, ensure continuous operation, meaning energy isn’t wasted in the frequent startup and shutdown cycles required for repairs or replacements.

Example:

Consider a pump system that uses tungsten carbide bushings. Instead of replacing bushings every year, the system can continue to run smoothly for five or more years.

This not only reduces the need for spare parts but also prevents the energy loss associated with constant system restarts.

Advantage 3: Less Downtime, More Operational Efficiency

Another key factor in improving energy efficiency is reducing downtime. When machines are offline for maintenance or part replacement, energy is wasted.

Tungsten carbide bushings contribute to less downtime by lasting longer and requiring less frequent maintenance.

Fewer repairs mean fewer disruptions to the production process, and fewer energy-intensive reboots or system recalibrations.

In industries where equipment downtime can be costly, the long lifespan of tungsten carbide bushings is an important factor in maintaining operational efficiency.

With fewer interruptions, companies can maintain steady energy consumption throughout their operations.

Example:

In an automotive assembly line, machines using tungsten carbide bushings may only need to be shut down for maintenance once every 3–5 years instead of every year.

This extended operational time means less energy is used in restarting the equipment and adjusting the settings, ultimately leading to lower energy costs.

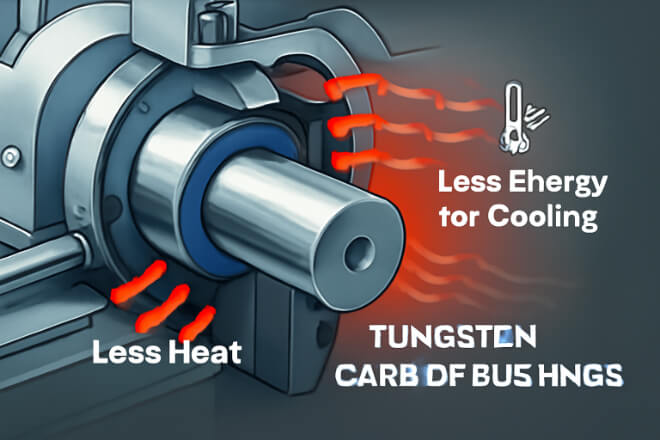

Advantage 4: Reduced Heat Generation for Improved Efficiency

Excessive heat generation in machinery is a sign of inefficiency and can lead to increased energy consumption.

When parts experience high friction or wear out, more heat is produced, which often requires additional energy to cool the system down.

Tungsten carbide bushings significantly reduce heat generation due to their low friction properties.

By maintaining a lower operating temperature, these bushings reduce the need for energy-intensive cooling systems, helping to improve overall energy efficiency.

This is especially important in industries such as mining, where equipment operates under harsh conditions and cooling systems can be a major source of energy waste.

Example:

In a mining operation, machinery with tungsten carbide bushings generates significantly less heat, which means less energy is needed for cooling.

As a result, cooling systems can be downsized or run less frequently, leading to a reduction in overall energy usage.

Advantage 5: Improved System Performance with Less Wear and Tear

With traditional bushings, parts degrade quickly, causing performance to drop and energy usage to rise. Tungsten carbide bushings maintain their high performance for much longer.

The material’s résistance à l'usure means that machinery operates smoothly for years, without the need for constant replacements or repairs that could disrupt efficiency.

By maintaining system performance over time, tungsten carbide bushings ensure that machines continue to run at peak efficiency, minimizing energy waste.

The longer the equipment runs efficiently, the less energy is required to keep the system in operation.

Example:

A high-speed machining system that uses tungsten carbide bushings can maintain precision and performance for years, avoiding the energy spikes typically caused by recalibration or replacement of worn parts.

This consistent performance reduces the need for energy-intensive adjustments and boosts overall system efficiency.

Conclusion

Tungsten carbide bushings offer numerous energy efficiency benefits, including reduced friction, extended equipment life, less downtime, and improved system performance.

By incorporating these durable and efficient components, industries can significantly lower their energy consumption and reduce operational costs.

For companies focused on sustainability, switching to tungsten carbide bushings is a smart move that not only saves energy but also contributes to a more sustainable and cost-effective operation.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.