Mechanical seals are small but critical components used in pumps, compressors, turbines, and mixers.

They prevent leaks, improve efficiency, and protect equipment in industries such as pétrole et gaz, chemical processing, water treatment, and power generation.

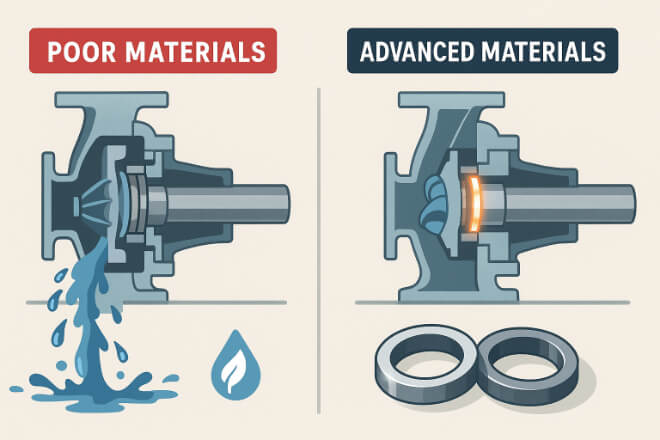

As machines face harsher environments, higher speeds, and stricter safety rules, traditional seal materials like stainless steel and carbon graphite are no longer enough.

The future of seal technology depends on advanced materials that provide greater strength, résistance à l'usure, and chemical stability.

This article explores the future material trends in mechanical seal technology, showing decision-makers what to expect and how to prepare.

Why Material Choice Matters in Mechanical Seals

Seal materials directly affect performance, cost, and safety. Poor material selection can cause:

Faster wear and shorter service life

Leaks in high-pressure systems

Failures in corrosive or hot environments

Higher maintenance and downtime costs

Future seal materials aim to solve these problems by providing better hardness, corrosion resistance, toughness, and thermal stability.

Trend 1: Tungsten Carbide Innovations

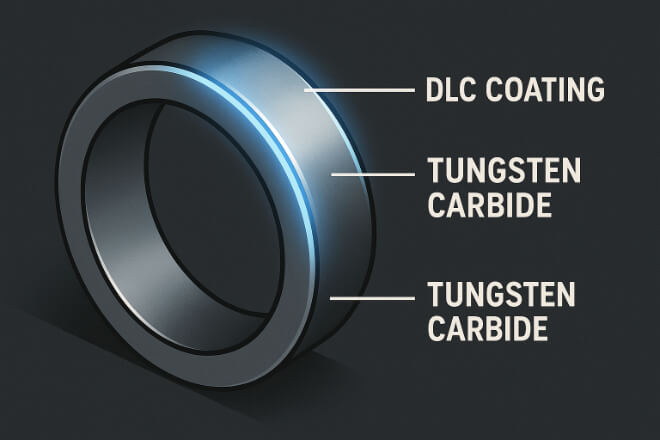

Tungsten carbide is already one of the most popular choices for seal rings. In the future, new grades and coatings will make it even more effective.

Carbure de tungstène lié au nickel → greater résistance à la corrosion for chemical and seawater applications

Carbure de tungstène lié au cobalt → better toughness for pétrole, gaz, et les industries minières

Advanced coatings → diamond-like carbon (DLC) coatings to reduce friction and extend life

These improvements will keep tungsten carbide central to seal technology.

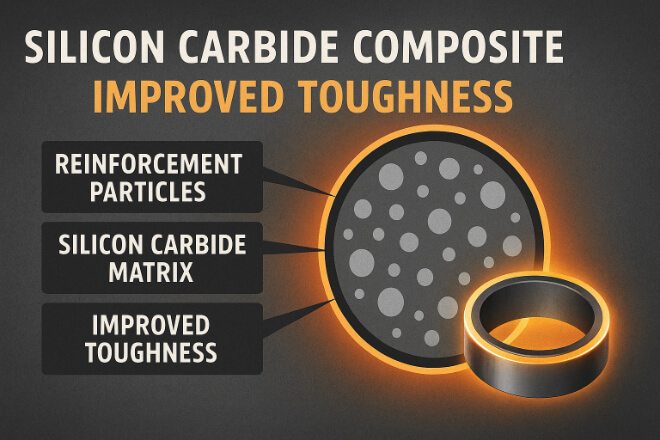

Trend 2: Silicon Carbide Advancements

Silicon carbide is known for corrosion resistance and lightweight properties. Future innovations include:

Enhanced toughness grades → to reduce brittleness and cracking

Sintered silicon carbide → providing better densité et résistance à l'usure

Hybrid composites → combining silicon carbide with carbon or ceramic for specialized needs

Silicon carbide will grow in importance, especially in chemical and water treatment systems.

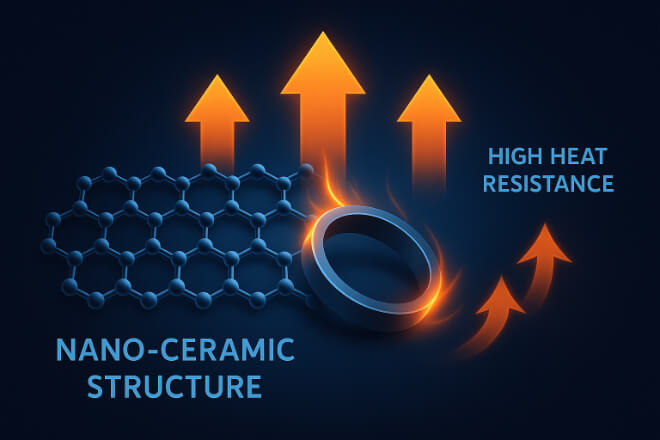

Trend 3: Ceramics and Advanced Composites

Ceramic seal materials offer high dureté and thermal resistance but are fragile. Future trends focus on:

Nano-ceramics → stronger and less brittle than traditional ceramics

Ceramic-metal composites → combining toughness of metals with hardness of ceramics

3D-printed ceramics → allowing custom designs and faster production

These materials will be key in aerospace and high-temperature energy applications.

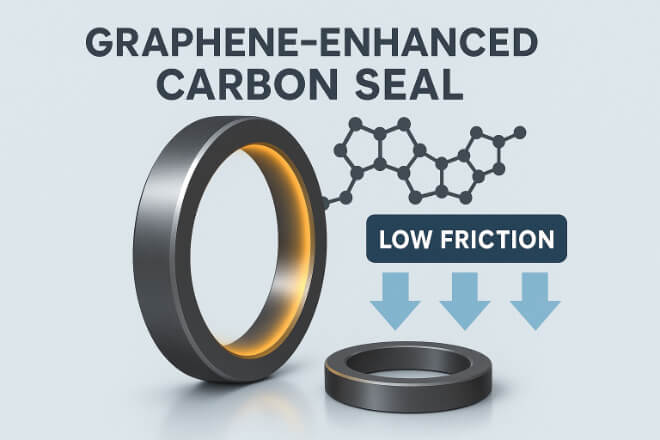

Trend 4: Carbon-Based Materials

Carbon graphite remains a classic choice because of its self-lubrication. In the future, improvements will include:

Resin-impregnated carbon → for higher résistance à l'usure

Carbon composites with fibers → to increase strength without losing lubrication

Graphene-enhanced seals → offering exceptional low friction and chemical resistance

These advances will make carbon seals more useful in fast-moving machinery and clean environments.

Trend 5: Coatings and Surface Engineering

Surface treatments will play a major role in seal technology:

Diamond-like carbon (DLC) coatings → ultra-low friction and high wear resistance

Thermal spray coatings → adding corrosion protection for extreme fluids

Nano-coatings → improving both hydrophobic and anti-corrosion properties

This trend shows that the future is not only about new materials but also about improving existing ones with better surfaces.

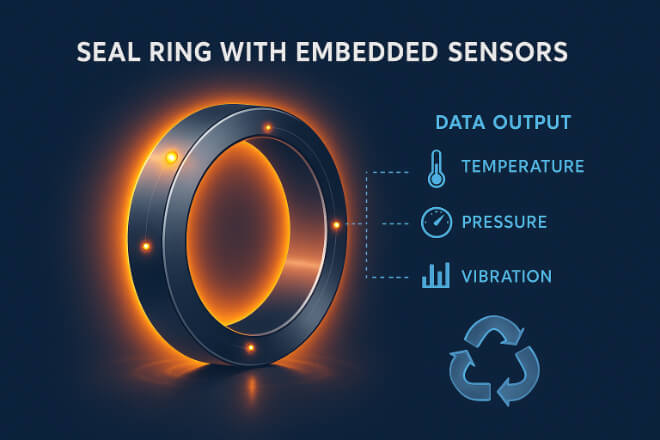

Trend 6: Smart and Self-Healing Materials

One of the most exciting developments is the rise of smart materials:

Self-healing polymers and composites → automatically repair small cracks

Materials with sensors → able to monitor wear and temperature in real-time

Adaptive materials → change properties under pressure or heat to improve sealing

Although still in research, these materials may transform seal technology in the next decade.

Trend 7: Sustainability and Recycling

Future materials must also meet sustainability goals:

Recyclable tungsten carbide → reducing waste and lowering cost

Eco-friendly composites → designed for less environmental impact

Circular economy approaches → reclaiming worn seals and reprocessing materials

For industries under stricter environmental rules, sustainable seal materials will become essential.

Benefits of Future Materials for Decision-Makers

Longer service life → fewer replacements and less downtime

Improved safety → stronger seals reduce risk of leaks and accidents

Des coûts de maintenance réduits → advanced materials reduce wear and failures

Higher efficiency → polished and coated seals reduce friction and energy use

Stronger ROI → higher upfront cost is balanced by long-term savings

Comparison of Material Trends

| Matériel | Future Improvements | Principaux avantages |

|---|---|---|

| Carbure de tungstène | New grades, advanced coatings | Durability, toughness, corrosion resistance |

| carbure de silicium | Hybrid composites, better toughness | Corrosion resistance, lightweight |

| Céramique | Nano-ceramics, composites | High hardness, heat resistance |

| Carbon-Based | Graphene, fiber composites | Low friction, lubrication |

| Smart Materials | Self-healing, sensor integration | Real-time monitoring, adaptive performance |

Exemples de cas

1). Pétrole et gaz

New tungsten carbide grades with DLC coatings improved pump seal life by 50%.

2). Traitement chimique

Hybrid silicon carbide seals reduced failures in acid-handling pumps.

3). Aerospace

Nano-ceramic seals improved performance in jet engines operating at extreme heat.

How to Prepare for Future Material Trends

Work with Innovative Suppliers – Choose partners investing in new materials.

Evaluate Life-Cycle Cost – Consider total ROI, not just purchase price.

Invest in Training – Teams must understand new materials and coatings.

Adopt Early – Early adoption brings competitive advantage in efficiency and safety.

Conclusion

The future of mechanical seal technology lies in better materials.

From advanced tungsten carbide grades to graphene-enhanced carbon, from nano-ceramics to self-healing composites, the next generation of seals will be stronger, safer, and more efficient.

For decision-makers, preparing now means staying ahead of competitors, reducing downtime, and ensuring long-term profitability.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.