In industries like machining, mining, and construction, efficiency is key to reducing costs and increasing productivity. One often-overlooked factor that can significantly impact production efficiency is the quality and customization of the tools used.

Tungsten carbide tips are known for their durability and résistance à l'usure, but customizing them to suit specific production needs can further optimize performance.

In this blog, we will explore how custom tungsten carbide tips can improve your production efficiency and help your business stay competitive in the industry.

1. Tailored to Specific Applications

Standard tungsten carbide tips may not always be the best fit for specialized tasks.

Custom tungsten carbide tips can be designed to meet the exact requirements of your production process, whether it’s cutting, drilling, or grinding.

By tailoring the size, geometry, and material properties of the tips, you can ensure they perform optimally under the specific conditions of your operation.

Key Benefits:

Customized Geometry: Custom tips can be designed for optimal cutting angles or shapes that best fit the workpieces, improving accuracy and reducing tool wear.

Material Adjustments: Customization allows for fine-tuning the tungsten carbide mixture, ensuring the tips have the right balance of dureté, dureté, et résistance à l'usure for your production needs.

By sourcing custom tungsten carbide tips, companies can minimize inefficiencies caused by using generic tools that aren’t suitable for specific tasks.

2. Improved Tool Life and Durability

One of the main advantages of using custom tungsten carbide tips is the extended tool life.

When tools are tailored to the production environment, they wear less quickly and last longer, which leads to fewer replacements and reduced downtime.

Custom tips can be engineered with the right coatings and material combinations to withstand the harshest conditions, from high temperatures to aggressive wear.

Key Benefits:

Coatings for Protection: Custom tips can be coated with materials like titanium nitride (TiN) or chromium nitride (CrN) to provide extra protection against wear, corrosion, and heat.

Enhanced Résistance à l'usure: The right material mixture can be selected to increase resistance to abrasive forces, ensuring the tips maintain sharpness and precision for a longer period.

With a longer tool life, businesses can reduce maintenance costs, minimize production interruptions, and enhance overall productivity.

3. Reduced Downtime and Maintenance Costs

Using custom tungsten carbide tips can significantly reduce downtime. Since these tips are designed for better durability and optimized for your specific production needs, they are less likely to fail unexpectedly.

This means fewer disruptions to your workflow and less time spent on tool replacements and maintenance.

Key Benefits:

Moins de remplacements d'outils: Custom tips are less prone to breakage, meaning you won’t have to stop production to replace worn-out tools.

Easier Maintenance: With custom tips, you can streamline your tool maintenance schedule, saving both time and labor costs.

This reduction in downtime is critical for businesses that need to keep their operations running smoothly and efficiently.

4. Higher Precision and Consistency

Custom tungsten carbide tips are designed to fit the exact requirements of the task at hand, allowing for higher precision in every operation.

This is especially important in industries where even the smallest deviations can lead to significant defects or rework costs.

Key Benefits:

Precise Cutting Edges: Custom tips can be made with sharper or more precise cutting edges, improving accuracy and reducing the chances of defects in the finished product.

Consistent Performance: Custom tips are engineered for consistency in performance, ensuring that each tool produces the same high-quality results, batch after batch.

In industries where quality and precision are crucial, custom tips help maintain high standards of production and reduce the risk of errors.

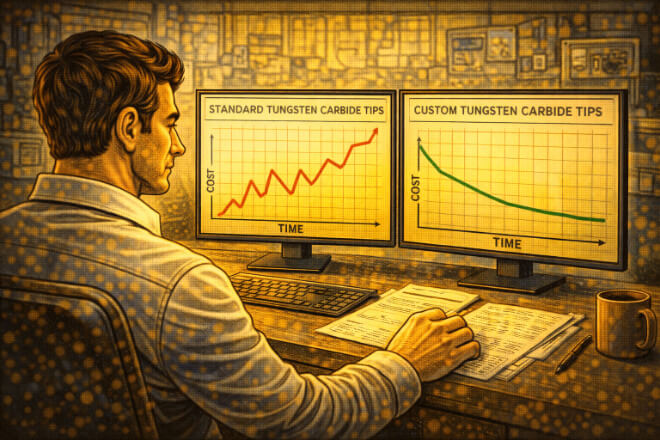

5. Cost Efficiency in the Long Run

Although custom tungsten carbide tips might have a higher initial cost compared to standard tips, the long-term cost savings are significant.

With their longer lifespan, improved performance, and reduced need for replacements and repairs, custom tips can be a cost-effective investment for your business.

Key Benefits:

Lower Operational Costs: By improving tool life and reducing maintenance needs, custom tips help lower the overall cost of production.

Fewer Defects and Rework: Custom tips designed for high precision also reduce the likelihood of defects, minimizing the cost of rework and waste.

In the long run, the cost-effectiveness of custom tungsten carbide tips can outweigh the initial investment, leading to better profitability and efficiency.

6. Optimized for Harsh Environments

In industries like mining and oil drilling, tools are subjected to extreme conditions such as high temperatures, pressure, and abrasive materials.

Custom tungsten carbide tips can be specially designed to withstand these harsh environments, providing a much higher level of durability than standard options.

Key Benefits:

Résistance à la température: Custom tips can be engineered to resist thermal shock and high-temperature degradation, making them ideal for applications where heat is a concern.

Corrosion and Abrasion Resistance: Coatings and specific material choices can be made to prevent corrosion and resist the abrasive forces found in mining or drilling applications.

For industries operating in challenging environments, custom tungsten carbide tips are an essential tool for ensuring that production continues efficiently without frequent interruptions.

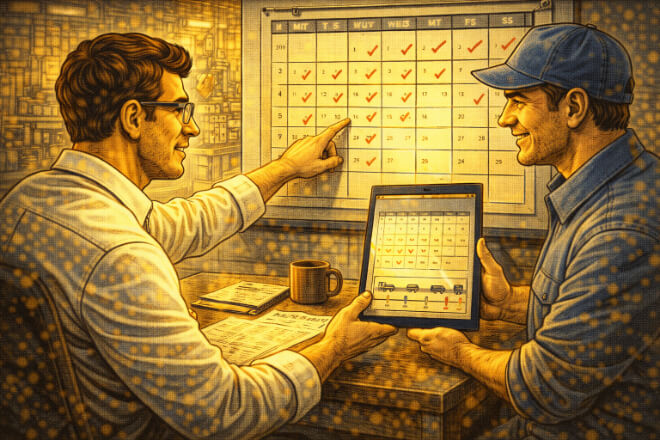

7. Better Supply Chain Management

Working with a manufacturer that offers custom tungsten carbide tips also gives companies greater control over their supply chain.

With customized products, businesses can place bulk orders or negotiate delivery schedules that align with their production timelines, reducing the need for emergency replacements.

Key Benefits:

Tailored Production Schedules: Manufacturers can adjust production to meet your specific needs, ensuring timely delivery of custom tips when you need them.

Qualité constante: Ordering custom tips ensures consistent product quality, reducing the risk of receiving mismatched or substandard tools from third-party suppliers.

Having a direct relationship with a manufacturer for custom tungsten carbide tips allows businesses to manage their inventory and production needs more effectively.

Conclusion

Custom tungsten carbide tips provide numerous benefits that can directly improve your production efficiency. From tailored designs that fit specific applications to extended tool life, better precision, and cost savings, the advantages are clear.

By investing in custom solutions, businesses can reduce downtime, improve productivity, and ensure that their operations run smoothly.

Whether you’re working in machining, mining, or any other industry, custom tungsten carbide tips offer a smart, long-term solution to optimizing your production process.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.