In high-performance machinery, the fit between the shaft and the tungsten carbide bushing determines how efficiently and reliably the system operates.

A precision fit ensures correct alignment, minimizes friction, prevents vibration, and extends the lifespan of both the shaft and the bushing.

Even if the bushing is made from high-quality tungsten carbide, poor fitting can lead to overheating, wear, or seizure.

This article explains how to achieve the correct fit, what factors affect it, and how to measure and maintain precision for long-term performance.

Understanding the Importance of Fit

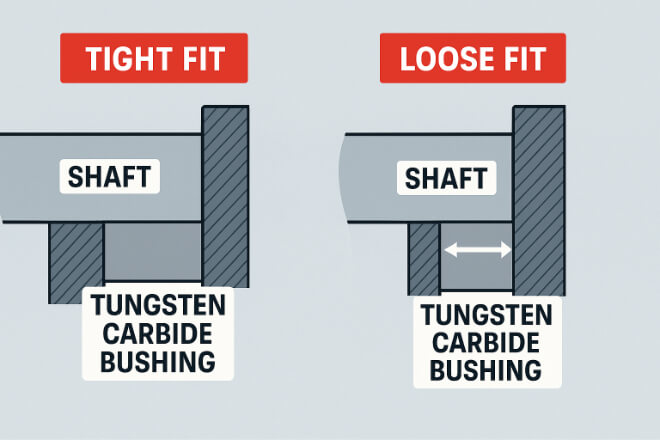

The term fit refers to the relationship between the shaft diameter and the bushing bore diameter.

A good fit ensures smooth rotation, controlled clearance for lubrication, and minimal radial play.

If the fit is too tight, the shaft may seize or cause cracks in the bushing. If it’s too loose, vibration and misalignment occur, leading to premature wear.

In essence, achieving the correct fit means finding the balance between mechanical stability and ease of assembly.

Types of Fits Used in Tungsten Carbide Bushings

There are three general categories of fits used in mechanical assemblies:

| Fit Type | Description | Application typique |

|---|---|---|

| Clearance Fit | Shaft diameter is smaller than bushing bore; allows free movement | Low-speed rotating parts or lubricated pumps |

| Transition Fit | Shaft and bore are nearly equal; balance between freedom and tightness | Medium-speed machinery or compressors |

| Interference Fit | Shaft diameter is slightly larger than bushing bore; press-fit required | High-speed turbines or fixed bushings |

Each fit type serves different operational needs. Selecting the correct one depends on speed, load, temperature, and lubrication type.

Factors That Affect Fit Accuracy

Several factors influence the actual fit achieved between the shaft and tungsten carbide bushing:

Manufacturing Tolérances – Even small deviations in diameter (±0.002 mm) affect performance.

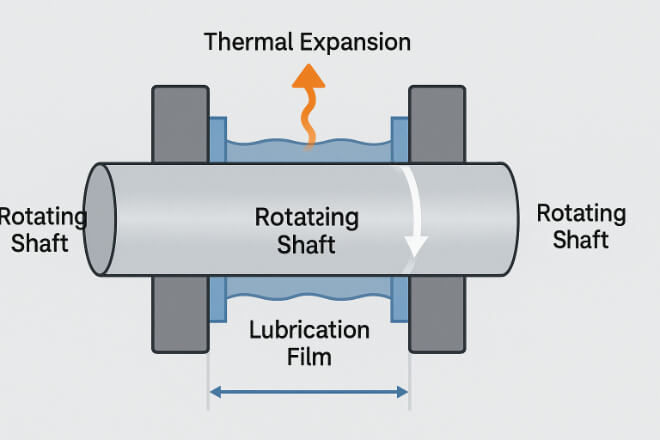

Thermal Expansion – The shaft and bushing expand differently when heated.

Matériel Dureté – Tungsten carbide is rigid and brittle; steel shafts are flexible.

Lubrication Film Thickness – Oil or process fluids reduce contact but change effective clearance.

Assembly Method – Press-fit or thermal-fit techniques alter final dimensions slightly.

Recommended Tolerances for Precision Fit

When precision matters, specifying tight tolerances is critical. Below is a guide for recommended shaft–bushing fits in various applications.

| Application | Fit Type | Clearance Range (mm) | Typical Shaft/Bushing Combination |

|---|---|---|---|

| Low-Speed, Light Load | Clearance Fit | 0.020 – 0.040 | Steel shaft + WC-Co bushing |

| Medium-Speed, Moderate Load | Transition Fit | 0.005 – 0.020 | Stainless shaft + WC-Ni bushing |

| High-Speed, High-Pressure | Interference Fit | −0.005 – −0.015 | Alloy shaft + fine-grain WC-NiCr bushing |

For press-fitted bushings, allow for expansion during installation — especially when using thermal methods.

Measuring and Verifying the Fit

Precision fit cannot be achieved without accurate measurement.

Common methods include:

Micrometer or bore gauge for diameters.

Air gauge system for very small clearances.

CMM (Coordinate Measuring Machine) for 3D verification.

Blue contact check to confirm surface matching between shaft and bushing.

It’s good practice to measure both parts at ambient temperature and under controlled humidity to minimize error.

Thermal and Mechanical Assembly Techniques

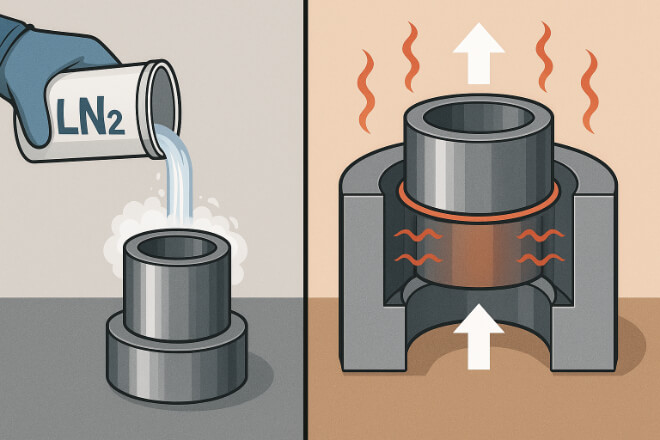

To install a bushing with a precise fit, engineers often use one of two methods:

1). Press-Fit Method

Bushing is mechanically pressed into the housing.

Provides strong retention but risks cracking if overpressured.

2). Thermal-Fit Method

Heat expands the housing or cool the bushing with liquid nitrogen before assembly.

As temperature equalizes, the bushing locks securely in place.

Reduces mechanical stress compared to direct pressing.

Pour bagues en carbure de tungstène, thermal-fit is often safer because it avoids tensile stress in the brittle carbide.

Surface Finish and Lubrication’s Role in Fit

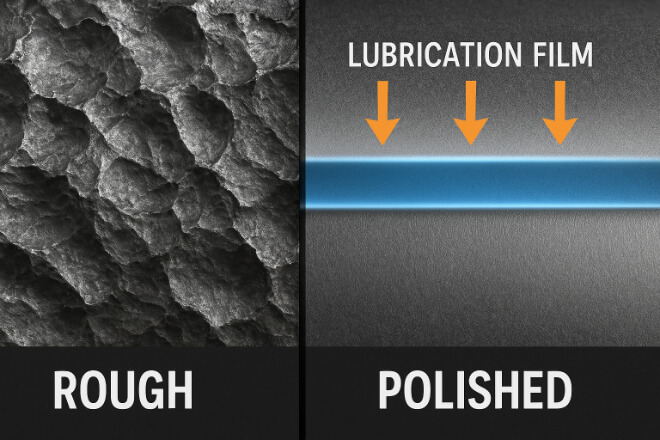

A perfect dimensional fit means little if surface finish is poor. Surface finish determines how well lubricant films form between the shaft and bushing.

Ra 0.1–0.2 µm is ideal for precision lubricated fits.

Mirror-like finishes reduce friction and wear.

Rough surfaces cause localized heating and pitting.

Always ensure that the shaft and bushing materials are compatible with the lubricant — especially in chemical or marine systems.

Preventing Common Fitting Problems

Even well-designed systems can fail if assembly or maintenance is mishandled.

Here are common fitting issues and their solutions:

| Problème | Likely Cause | Recommended Action |

|---|---|---|

| Usure excessive | Loose fit or poor lubrication | Regrind shaft or rehone bushing to correct clearance |

| Seizure During Operation | Interference too tight; thermal expansion | Recalculate fit considering operating temperature |

| Cracks in Bushing | Press-fit applied unevenly | Use thermal-fit instead of mechanical press |

Avoid forcing assembly. Always check concentricity and shaft alignment before final tightening.

Inspection and Maintenance for Long-Term Precision

Regular inspection ensures that wear and clearance remain within acceptable limits.

Recommended practices include:

Measuring bore diameter and shaft OD every 6 months.

Monitoring vibration and temperature during operation.

Re-polishing surfaces if Ra exceeds 0.3 µm.

Replacing bushings once wear exceeds 10% of initial clearance.

Preventive maintenance avoids unplanned downtime and protects the entire shaft–bearing system.

Conclusion

Achieving a precision fit between a shaft and tungsten carbide bushing is a process of design, measurement, and control.

By selecting the right fit type, maintaining tight tolerances, and using proper installation techniques, companies can achieve smooth operation, longer equipment life, and reduced maintenance cost.

Precision fitting is not only a machining standard — it’s a strategic investment in reliability and performance.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.