Pièces d'usure en carbure de tungstène are known for their high dureté, résistance à l'usure, et une longue durée de vie.

They are used in industries such as exploitation minière, pétrole et gaz, metal forming, and manufacturing, where equipment works in tough environments.

However, even the best tungsten carbide parts can fail early if they are not used and maintained correctly.

For decision-makers, extending the life of these components is not just about saving money on replacements—it is also about reducing downtime, improving productivity, and protecting investment in machinery.

This article explains simple, practical steps to make tungsten carbide wear parts last longer.

Choose the Right Grade for the Job

Not all tungsten carbide is the same. Different grades are designed for specific operating conditions.

Factors to consider when selecting a grade:

Dureté vs. dureté: Harder grades resist abrasion better, but may break under heavy impact. Tougher grades handle shock but wear faster.

Binder content: Higher cobalt binder improves toughness, lower binder increases hardness.

Grain size: Fine grain improves résistance à l'usure, coarse grain increases toughness.

| Type de note | Main Feature | Idéal pour |

|---|---|---|

| Dureté élevée | Excellent abrasion resistance | Sand, slurry, and fine particle wear |

| Haute ténacité | Resists impact and chipping | High impact tools, drilling |

| Balanced Grade | Good mix of hardness and toughness | General wear protection |

Tip: Always match the grade to the actual wear mechanism in your application. Choosing the wrong grade can cut lifespan by more than half.

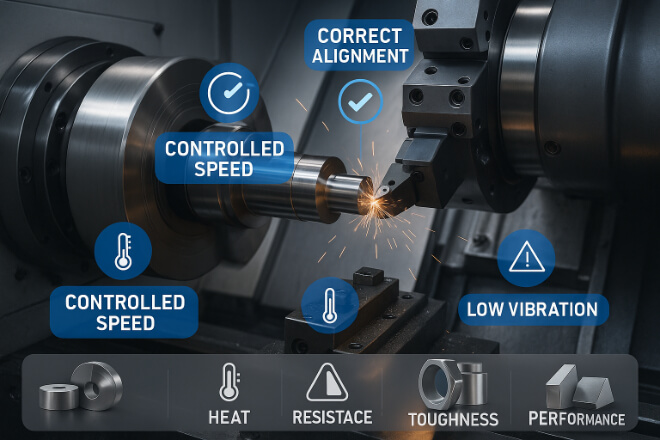

Maintain Correct Operating Conditions

Even the hardest material can fail if machinery runs under harmful conditions.

Key areas to monitor:

Alignment: Misaligned parts create uneven wear and stress.

Speed and pressure: Excessive speed or load generates heat and fractures.

Vibration control: Continuous vibration weakens carbide and can cause cracks.

Decision-maker’s action: Ensure operators are trained to stay within recommended machine settings and avoid overloading the parts.

Use Proper Lubrication and Coolant

Lubrication is critical for reducing friction, while coolant controls heat buildup.

Best practices:

Use the correct type of lubricant for your process.

Ensure coolant flow reaches all contact points.

Check coolant cleanliness—contaminants can cause abrasion.

Avoid dry running unless parts are designed for it.

Why it matters: Excess heat softens the binder metal in carbide, making it easier for particles to break off.

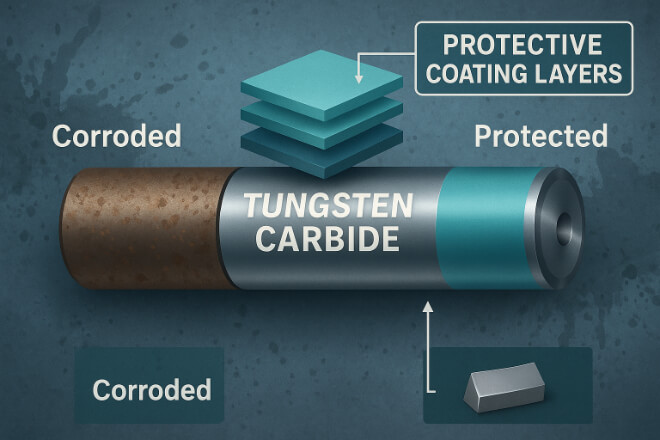

Protect Against Corrosion

Tungsten carbide itself is resistant to corrosion, but its binder (usually cobalt) can corrode in acidic or alkaline conditions.

Preventive measures:

Apply protective coatings (like nickel or chrome plating).

Use corrosion inhibitors in coolant systems.

Select nickel-bonded carbide grades for high-corrosion environments.

Clean Parts Regularly

Build-up of dirt, metal chips, or scale increases friction and accelerates wear.

Cleaning tips:

Use non-abrasive methods to avoid scratching the surface.

Clean during scheduled maintenance, not only after problems appear.

Dry parts fully after cleaning to prevent rust on non-carbide areas.

Apply Surface Coatings for Extra Protection

Surface coatings can add an extra barrier against abrasion, corrosion, and heat.

Common coatings:

TiN (Titanium Nitride): Improves wear resistance.

TiAlN (Titanium Aluminum Nitride): Good for high-heat applications.

CrC (Chromium Carbide): Excellent for corrosion and oxidation resistance.

Tip: Coatings work best when the base carbide is in good condition. Coating a worn part will not restore its original strength.

Store Wear Parts Properly

Improper storage can damage tungsten carbide before it is even used.

Storage guidelines:

Keep parts in dry, clean, and temperature-controlled areas.

Avoid stacking carbide parts without padding—they can chip each other.

Store in labeled compartments to avoid mix-ups between grades.

Monitor Wear with Inspection Schedules

Preventive maintenance is cheaper than emergency replacement.

Inspection checklist:

Look for chipping, cracking, or pitting.

Measure dimensional changes against original specs.

Record wear data to predict replacement intervals.

| Inspection Interval | Key Checks |

|---|---|

| Hebdomadaire | Visual inspection for cracks or chips |

| Mensuel | Dimensional measurement, coating condition |

| Quarterly | Full wear analysis and maintenance report |

Train Staff on Handling and Use

Even the best maintenance plan will fail if people handling the parts are not careful.

Training focus areas:

Proper installation techniques

Avoiding impact damage during assembly

Understanding limits of each part’s design

Work with Reliable Suppliers

Choosing a trustworthy supplier ensures you get consistent quality and technical support.

Supplier advantages:

Access to expert advice on grade selection.

Quality assurance testing on every batch.

After-sales service and troubleshooting.

Conclusion

Extending the life of tungsten carbide wear parts is a combination of choosing the right material, maintaining good operating conditions, protecting against heat and corrosion, and training staff.

These steps help decision-makers reduce costs, avoid downtime, and keep production running smoothly.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.