Dans l'usinage moderne, vitesse et précision sont primordiales. Que vous produisiez des pièces dans un atelier CNC ou que vous gériez une production à grande échelle, la qualité de vos outils de coupe affecte directement votre production, vos coûts et la qualité de vos produits.

C'est pourquoi de plus en plus d'industries passent des outils traditionnels aux outils de coupe en carbure de tungstène.

Mais qu'est-ce qui les rend si spéciaux ? Et comment améliorent-ils précisément vos performances d'usinage ?

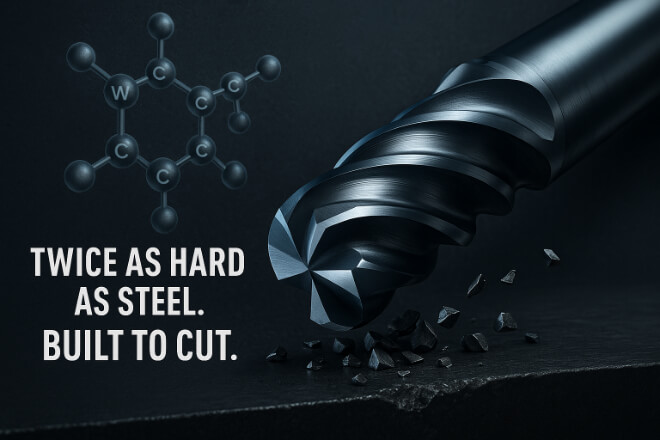

1. Qu'est-ce que le carbure de tungstène ?

Le carbure de tungstène est un composé composé d'atomes de tungstène et de carbone. Il est extrêmement dur – presque deux fois plus dur que l'acier – et peut supporter des températures élevées sans ramollir.

En fait, c'est l'un des matériaux les plus durs utilisés dans la fabrication, derrière les diamants et quelques céramiques avancées.

Ces propriétés le rendent parfait pour les outils de coupe utilisés dans le fraisage, le tournage, le perçage et le meulage.

Alors que les outils en acier rapide (HSS) sont moins chers, les outils en carbure restent plus affûtés, coupent plus rapidement et durent beaucoup plus longtemps, en particulier dans des conditions d'usinage difficiles ou avec des matériaux difficiles.

2. Pourquoi les outils de coupe sont importants dans l'usinage

On a tendance à négliger les outils de coupe : ils sont petits et souvent un élément d'une machine plus grande. Pourtant, ils jouent un rôle essentiel dans l'efficacité et la précision de vos opérations.

L’utilisation d’un outil inapproprié peut entraîner :

Finitions de surface rugueuses

Augmentation de la casse des outils

Arrêts fréquents des machines

Des coûts de production plus élevés

Déchets de matériaux excédentaires

Problèmes de sécurité liés à une défaillance de l'outil

Le bon outil en carbure de tungstène vous offre :

Des temps de cycle plus rapides

Meilleure précision des pièces

Moins d'usure des outils et moins de remplacements

Des résultats de meilleure qualité

Une productivité accrue à chaque changement de machine

Pour les ateliers axés sur la croissance, la rentabilité et la précision, les outils de coupe ne sont pas seulement des accessoires : ils sont des composants essentiels de l'ensemble du système d'usinage.

3. Comment le carbure de tungstène améliore l'efficacité de l'usinage

Explorons comment les outils de coupe en carbure améliorent spécifiquement l'efficacité de votre processus d'usinage :

1). Vitesses de coupe plus rapides

Outils en carbure de tungstène Peut supporter des vitesses de coupe bien supérieures à celles des outils en acier. Cela vous permet :

Faire fonctionner les machines à un régime plus élevé

Utiliser des débits d'alimentation agressifs

Enlever le matériau plus rapidement

Terminez les travaux en moins de temps

Surtout dans les environnements de production à volume élevé, cette augmentation de vitesse peut se traduire par des milliers de dollars économisés en main-d'œuvre et en heures de machine chaque mois.

2). Moins de changements d'outils

Les outils en carbure résistent bien mieux à la chaleur et à l'abrasion que les outils en acier rapide. Ceci permet :

Changements d'outils moins fréquents

Interruption de production réduite

Risque réduit d'erreur humaine lors du changement d'outil

Durée de fonctionnement de la machine plus longue par quart de travail

Même si le coût initial du carbure est plus élevé, la durée de vie prolongée de l'outil et les exigences de manipulation réduites les rendent plus rentables à long terme.

3). Performances constantes des outils

Les outils en carbure restent affûtés plus longtemps et offrent des performances de coupe constantes, même lors de l'usinage de matériaux durs comme le titane, l'Inconel ou l'acier à outils. Cette constance se traduit par :

Qualité de surface uniforme sur de grands lots

Tolérances de pièces fiables

Moins de pièces de rebut ou de retouches

Paramètres de processus stables dans le temps

Ceci est particulièrement important dans les secteurs où la qualité doit être garantie pour des raisons de sécurité ou de réglementation.

4). Prise en charge de l'usinage automatisé

Alors que de plus en plus d'usines se tournent vers l'automatisation et la production en autonomie, les outils de coupe doivent suivre le rythme. Le carbure est idéal pour ces systèmes car :

Il fonctionne à des vitesses et des débits d'alimentation élevés

Il résiste à la déflexion de l'outil et aux dommages causés par la chaleur

Il prend en charge les changeurs d'outils robotisés et les cycles sans pilote

Il minimise les pannes d'outils inattendues qui peuvent arrêter la production

L'outillage en carbure est prêt pour l'automatisation, aidant les fabricants à améliorer leur production sans augmenter leurs effectifs.

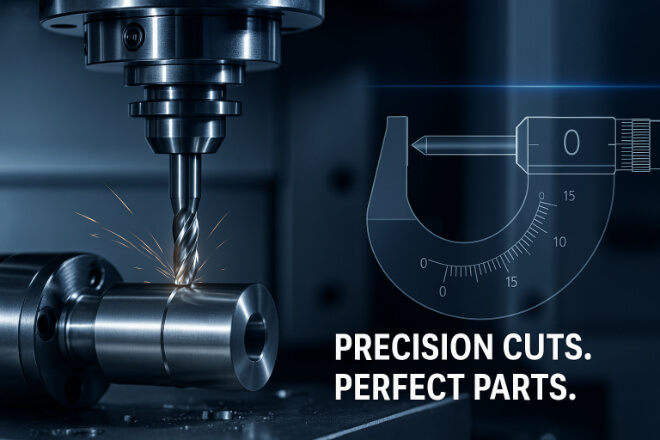

4. Comment les outils en carbure améliorent la précision

La vitesse est excellente, mais qu'en est-il de la précision ? C'est là que le carbure de tungstène excelle.

1). Tolérances plus strictes

La dureté et la rigidité du carbure permettent des coupes précises avec une déflexion minimale de l'outil. Ceci contribue à :

Tolérances au niveau du micron

Géométrie parfaite des pièces

Meilleure compatibilité avec les autres composants

Des résultats cohérents d'une pièce à l'autre

2). Finitions de surface plus propres

Un outil en carbure bien affûté génère moins de vibrations et d'arrachements à la surface de coupe. Il en résulte :

Des finitions plus lisses

Moins de besoin de post-traitement ou de polissage

Meilleure adhérence du revêtement pour les pièces plaquées ou peintes

Esthétique et intégrité de surface améliorées

3). Moins de distorsion liée à la chaleur

Le carbure de tungstène dissipe efficacement la chaleur et résiste au ramollissement à haute température. Cela signifie :

Moins de risque de déformation thermique

Des coupes plus précises sur des pièces fines ou sensibles à la chaleur

Durée de vie prolongée de l'outil lors de l'usinage à sec ou semi-sec

Charge thermique réduite sur votre broche CNC

Dans les industries où même les petites inexactitudes comptent, le carbure est le matériau privilégié pour des résultats fiables.

5. Exemple concret : comparaison des résultats d'un atelier CNC

Voici un exemple rapide montrant la différence de performance entre les outils HSS et en carbure :

| Type d'outil | Temps de cycle (min) | Pièces par quart de travail | Qualité de la finition de surface | Durée de vie de l'outil |

|---|---|---|---|---|

| Fraise HSS | 12 | 40 | Moyen | 3 à 5 heures |

| Fraise en carbure | 5 | 100+ | Excellent | 15 à 20 heures |

Résultat : l’atelier a plus que doublé sa production quotidienne, amélioré la qualité de surface et réduit les remplacements d’outils, tout cela en passant au carbure de tungstène.

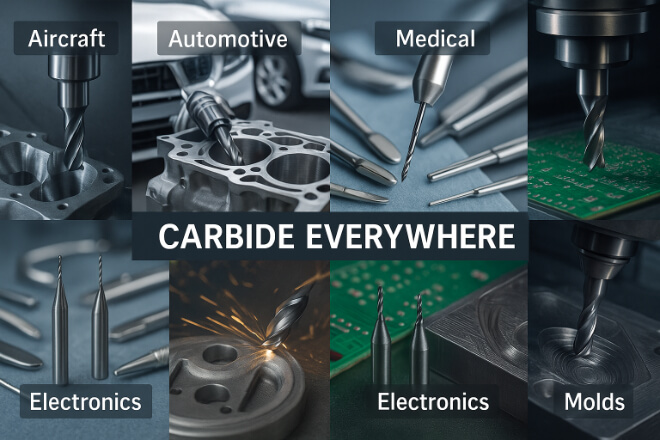

6. Applications courantes qui en bénéficient le plus

Les outils de coupe en carbure de tungstène sont reconnus dans de nombreux secteurs. Voici un aperçu de leurs points forts :

1). Aérospatial

Découpe de précision du titane et des superalliages

Fraisage à grande vitesse d'aubes de turbine

Maintien des tolérances sous des charges thermiques élevées

2). Automobile

Usinage de blocs moteurs, de composants de freins et d'engrenages

Soutenir la production à grande échelle avec une usure minimale des outils

Amélioration de la qualité de finition pour les ajustements critiques

Création d'implants chirurgicaux avec des tolérances strictes

Micro-perçage de trous fins dans l'acier inoxydable ou le cobalt-chrome

Assurer des coupes uniformes et sans bavures

Fraisage et perçage de haute précision

Coupes nettes sur les matériaux délicats en cuivre et composites

Maintenir la précision à des échelles miniatures

Gravure sur acier trempé et aciers à outils

Prise en charge des opérations d'ébauche et de finition fine

Réduire la casse des outils dans les cavités profondes

6). Pétrole et gaz

Coupe d'alliages résistants à la corrosion

Maintien de l'intégrité de l'outil dans des conditions de perçage difficiles

Améliorer la disponibilité des machines d'usinage sur le terrain

7). Travail du bois

Découpe de MDF, de contreplaqué et de composites

Durée de vie des bords plus longue, même avec des planches abrasives

Finition plus propre avec moins de passages

8). Horlogerie et Joaillerie

Gravure de précision de métaux et de pierres précieuses

Fraisage de détails ultra-fins et micro-façonnage

Travail délicat avec un contrôle maximal

7. Éléments à prendre en compte lors du choix d'outils en carbure

Pour exploiter pleinement les performances de votre outil, il vous faut un outil en carbure adapté à votre application. En savoir plus :

Compatibilité des matériaux – Certains revêtements fonctionnent mieux avec l’acier, d’autres avec l’aluminium

Géométrie – Choisissez le nombre de cannelures, l’angle de coupe et le rayon d’angle corrects pour chaque tâche

Capacité de la machine – Adaptez la conception de l'outil à la puissance de la broche, à la plage de régime et à la rigidité

Besoins en liquide de refroidissement – Certains outils sont optimisés pour l’usinage à sec, d’autres pour l’arrosage par inondation

Type de revêtement – TiAlN, AlCrN, DLC et autres améliorent la résistance à la chaleur et le contrôle des copeaux

8. Le carbure de tungstène vaut-il l’investissement ?

En un mot : oui.

Bien que le prix initial des outils en carbure soit plus élevé que celui des outils HSS, les avantages à long terme sont difficiles à ignorer :

Coût d'outillage réduit par pièce

Temps de disponibilité des machines plus élevé

Meilleur contrôle de la qualité

Taux de rebut et de reprise réduits

Retour sur investissement plus rapide sur l'équipement et la main-d'œuvre

Les outils en carbure sont rapidement rentabilisés, en particulier dans les secteurs concurrentiels où l’efficacité et la qualité font ou défont une entreprise.

Réflexions finales

Si votre atelier vise à couper plus rapidement, à réduire les déchets et à améliorer la précision des pièces, les outils de coupe en carbure de tungstène sont la solution.

Leur résistance, leur vitesse et leur précision en font une mise à niveau intelligente pour presque toutes les opérations d’usinage.

Que vous fraisiez de l'aluminium, perciez du titane ou coupiez du plastique, le carbure vous aidera à le faire mieux et plus intelligemment.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.