Tungsten carbide is one of the hardest and most résistant à l'usure materials used in modern industry. It is a composite material, made by combining tungsten carbide powder with a binder metal, usually cobalt or nickel.

When shaped into wear parts, it provides exceptional resistance to abrasion, impact, and high pressure.

For industries like exploitation minière, pétrole et gaz, construction, travail des métaux, et aérospatial, the manufacturing of pièces d'usure en carbure de tungstène is not only about producing tools – it is about ensuring durability, reducing downtime, and protecting machines.

This article explains, step by step, how tungsten carbide wear parts are manufactured, from raw materials to final inspection. It will also show why these processes are critical for decision-makers who want reliable and cost-effective solutions.

Step 1: Preparing Raw Materials

The first step in making tungsten carbide wear parts is preparing the raw powders.

Poudre de carbure de tungstène (WC) – provides dureté et wear resistance.

Binder metal (Co/Ni) – adds dureté and holds WC grains together.

Additives (VC, Cr₃C₂, TaC, TiC) – improve grain growth control and corrosion resistance.

The powders are carefully measured and blended to create the desired grade. For example:

A higher binder content = better toughness but less hardness.

A finer WC grain size = higher hardness but lower toughness.

This stage is crucial, because the composition defines the final performance of the wear part.

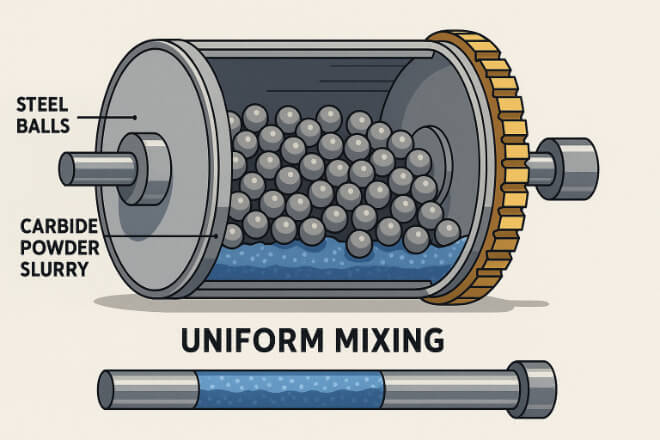

Step 2: Powder Mixing and Ball Milling

The powders are then mixed to achieve uniform composition.

The process uses wet ball milling, where powders are placed in a rotating drum with hard balls.

A liquid medium (often ethanol or water with additives) is added to prevent oxidation.

After several hours of milling, the result is a homogeneous powder mixture.

Uniform mixing ensures that every finished part has consistent hardness, density, and wear resistance.

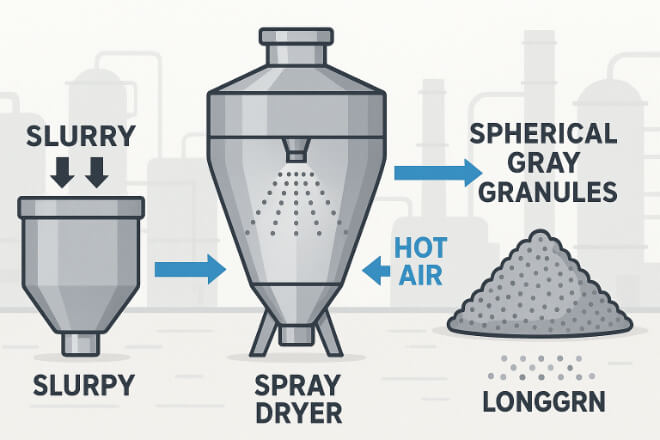

Step 3: Spray Drying into Granules

The mixed slurry cannot be pressed directly. It must first be converted into granules:

The slurry is fed into a spray dryer.

Hot air instantly dries the slurry into spherical granules.

These granules are free-flowing and press-ready, with consistent size and densité.

Spray drying helps ensure that during pressing, the parts achieve uniform density and fewer defects.

Step 4: Pressing into Green Compacts

The granules are pressed into shape using one of two methods:

Uniaxial pressing – for simple shapes like discs, rings, and blocks.

Cold Isostatic Pressing (CIP) – for larger or more complex parts, where pressure is applied evenly from all sides.

The result is called a “green compact”. It has the correct shape but is fragile and must be handled carefully before sintering.

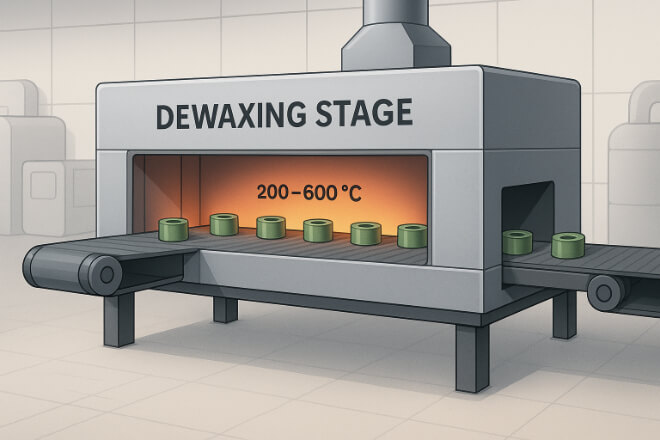

Step 5: Dewaxing Process

The granules contain wax or binder to help pressing. Before sintering, these must be removed.

The green compacts are heated in a dewaxing furnace.

Temperature gradually rises from 200–600 °C.

The wax evaporates without damaging the compact.

This step ensures the final part will have no internal voids or contamination.

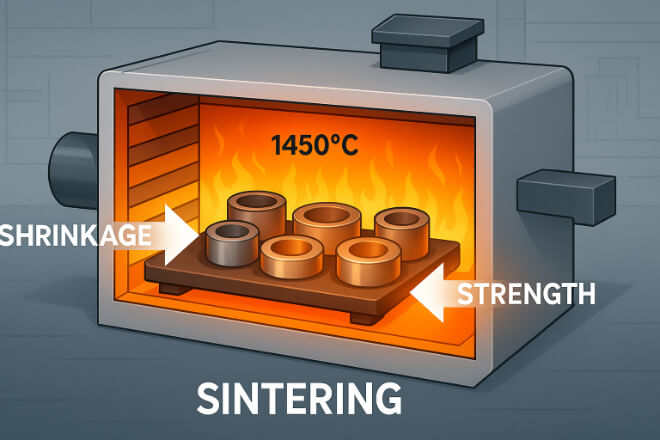

Step 6: Sintering in a High-Temperature Furnace

Sintering is the most important step.

Compacts are heated to 1400–1500 °C in a vacuum or controlled atmosphere furnace.

At this temperature, binder melts and bonds the WC grains together.

Shrinkage occurs (about 18–22%), and the part reaches its final strength.

For critical applications, Hot Isostatic Pressing (HIP) is added after sintering. HIP removes porosity and improves toughness.

The result is a dense, hard, and résistant à l'usure carbide part ready for finishing.

Step 7: Precision Grinding and Machining

Sintered carbide is extremely hard (HRA 89.5–92.5), so it must be finished with diamond grinding tools.

Centerless grinding – for bushings, balls, and cylindrical parts.

Surface grinding – for wear plates and strips.

Lapping and polishing – to achieve mirror-like finishes (Ra 0.02–0.05 µm).

This ensures parts meet tight tolerances (±0.002 mm) and perform reliably in service.

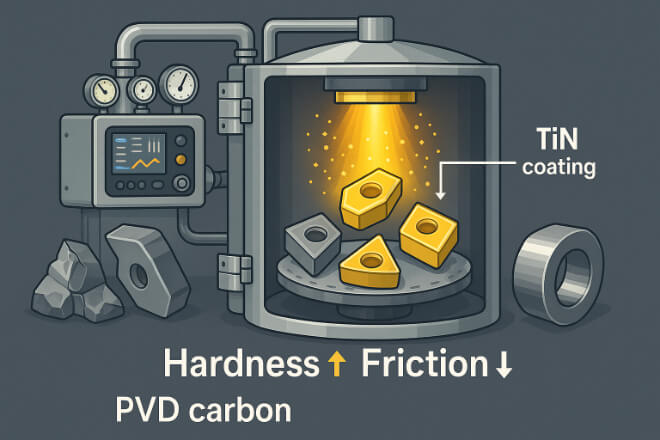

Step 8: Coating for Enhanced Performance

In some cases, tungsten carbide wear parts receive a protective coating to improve performance.

PVD coatings (TiN, TiAlN, DLC) – add extra hardness and reduce friction.

Chemical coatings – improve corrosion resistance.

Not all wear parts require coating, but for outils de coupe or high-speed applications, coatings extend tool life significantly.

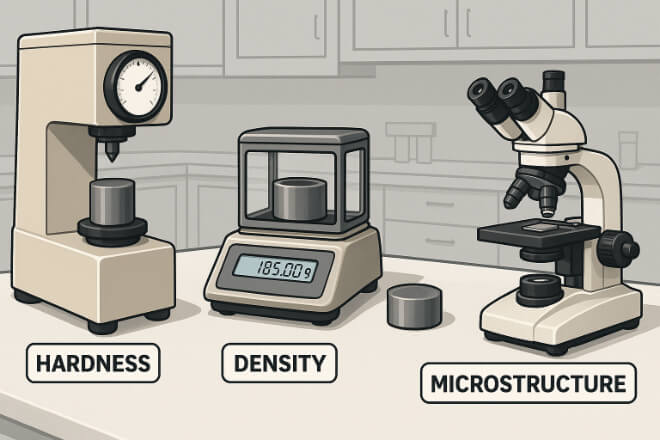

Step 9: Quality Inspection and Testing

Every finished part undergoes strict inspection to meet ISO standards. Common tests include:

Dureté test – Rockwell or Vickers (HRA 89.5–92.5).

Densité test – Archimedes method (14.5–15.0 g/cm³).

Microstructure check – microscope analysis of WC grain distribution.

Dimensional accuracy – digital calipers and CMM measurement.

This ensures that only high-quality, reliable parts are delivered to customers.

Step 10: Packaging and Shipping

Finally, parts are packed to protect against moisture, corrosion, and damage.

Each batch is labeled with grade, size, and batch number for traceability.

Desiccants are added to prevent moisture damage.

Secure packaging ensures carbide parts arrive safely at the customer’s facility.

Why Manufacturing Process Matters for Decision-Makers

For industry leaders, knowing how carbide wear parts are manufactured helps in making better supplier choices.

Consistent quality comes from strict powder preparation and sintering.

Longer service life results from advanced grinding and coating.

Reduced risk comes from suppliers that follow ISO-certified processes.

Choosing the right manufacturer means fewer failures, lower downtime, and higher efficiency in critical operations.

Conclusion

The manufacturing of tungsten carbide wear parts is a complex but highly controlled process.

From raw powder preparation to sintering, grinding, coating, and inspection, each step ensures that the final product can withstand extreme wear conditions.

For decision-makers, understanding this process is key to choosing reliable suppliers, reducing operational risk, and securing long-term performance.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.