In manufacturing, precision and efficiency are key to maintaining high-quality production while reducing costs.

One of the most effective ways to achieve this is by optimizing cutting parameters. Tungsten carbide tips are widely used in manufacturing for their durability and hardness.

By fine-tuning the cutting parameters and using tungsten carbide tips effectively, businesses can significantly improve their cutting performance, reduce tool wear, and enhance overall production efficiency.

This blog will explore how optimizing cutting parameters with tungsten carbide tips can lead to better manufacturing results.

1. Understanding Cutting Parameters in Manufacturing

Before diving into how tungsten carbide tips can optimize cutting, it’s important to understand what cutting parameters are and why they matter.

Cutting parameters refer to the settings and conditions under which cutting operations are performed. These parameters include:

Vitesse de coupe: The speed at which the cutting tool moves through the material.

Taux d'alimentation: The rate at which the workpiece moves relative to the cutting tool.

Profondeur de coupe: The thickness of the material being removed in a single pass.

By adjusting these parameters, manufacturers can influence the quality of the cut, tool life, and overall production efficiency.

The right combination of cutting parameters ensures optimal performance, especially when using tools like tungsten carbide tips.

2. The Role of Tungsten Carbide Tips in Cutting Operations

Tungsten carbide is known for its dureté, résistance à l'usure, and heat resistance, making it an ideal choice for cutting tools in manufacturing.

Tungsten carbide tips can withstand high cutting speeds and intense heat, which are often present in manufacturing environments.

These properties make them particularly suitable for demanding operations such as high-speed machining and precision cutting.

Key Benefits of Tungsten Carbide Tips:

Durée de vie de l'outil plus longue: Tungsten carbide tips can last longer than other materials due to their resistance to wear and thermal degradation.

Vitesses de coupe plus élevées: Tungsten carbide allows for higher cutting speeds, reducing cycle times and increasing productivity.

Finition de surface améliorée: Tungsten carbide tips can produce smoother, more precise cuts, leading to better surface finishes.

Optimizing cutting parameters with tungsten carbide tips ensures that manufacturers can achieve the best results without compromising tool life or cutting efficiency.

3. Optimizing Cutting Speed for Tungsten Carbide Tips

Cutting speed is one of the most critical parameters in manufacturing. When using tungsten carbide tips, it’s essential to find the optimal cutting speed to maximize efficiency and extend tool life.

Too high of a cutting speed can lead to excessive wear, while too low of a cutting speed can result in poor surface finish and reduced productivity.

Factors to Consider:

Material Hardness: Softer materials can typically be cut at higher speeds, while harder materials require slower cutting speeds to prevent tool wear.

Tool Geometry: Tungsten carbide tips with specific geometries, such as sharp cutting edges or certain coatings, can handle higher cutting speeds more effectively.

By fine-tuning the cutting speed, manufacturers can ensure that their tungsten carbide tips perform at their best, providing a balance between tool life and cutting efficiency.

4. Adjusting Feed Rate for Precision and Efficiency

Feed rate refers to how quickly the workpiece moves relative to the cutting tool. An optimal feed rate is crucial for maintaining precision while also ensuring that production remains efficient.

When using tungsten carbide tips, adjusting the feed rate properly can lead to better chip removal, smoother cuts, and longer tool life.

Key Considerations:

Chip Formation: A higher feed rate can lead to larger chips being formed, which can affect the surface finish and tool life. Tungsten carbide tips allow for higher feed rates compared to other materials without sacrificing quality.

Usure des outils: A feed rate that is too high can increase the cutting force, leading to premature wear of the tool. Properly adjusting the feed rate helps maintain a balance between speed and tool longevity.

By adjusting the feed rate according to the material being cut and the desired finish, manufacturers can achieve both high efficiency and precision with tungsten carbide tips.

5. Depth of Cut for Efficient Material Removal

Depth of cut refers to the amount of material being removed in a single pass.

Tungsten carbide tips are capable of handling deeper cuts without experiencing significant wear or thermal damage, making them ideal for heavy-duty cutting operations.

However, the depth of cut should be optimized to ensure efficient material removal while maintaining tool longevity.

Considerations for Depth of Cut:

Type de matériau: Harder materials often require a shallower depth of cut to prevent excessive heat buildup and tool wear.

Cutting Conditions: For high-speed applications, a shallower depth of cut may be necessary to avoid overloading the tool, while deeper cuts can be made for more robust materials or slower operations.

By optimizing the depth of cut, manufacturers can increase material removal rates without negatively affecting tool life or cutting precision.

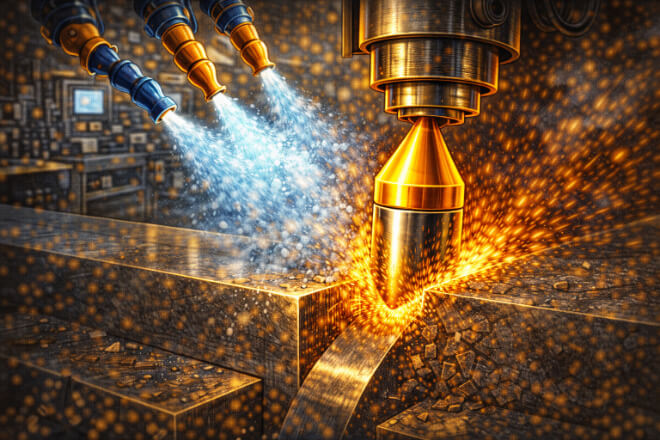

6. The Importance of Cooling and Lubrication

Cooling and lubrication play a significant role in optimizing cutting parameters, especially when using tungsten carbide tips.

High cutting speeds and deep cuts generate heat, which can cause thermal damage to the tool and the workpiece.

Proper cooling and lubrication reduce friction, dissipate heat, and prolong the life of the cutting tool.

Benefits of Cooling and Lubrication:

Reduced Heat Generation: Proper cooling ensures that the tungsten carbide tips maintain their dureté and resist thermal degradation.

Finition de surface améliorée: Lubricants help reduce friction between the tool and the material, leading to smoother cuts and better surface finishes.

Optimizing cooling and lubrication strategies can enhance the performance of tungsten carbide tips, ensuring that they remain effective even under demanding cutting conditions.

7. Monitoring and Adjusting Cutting Parameters in Real-Time

Modern manufacturing environments often use advanced monitoring systems to track cutting conditions in real-time.

These systems can measure parameters such as cutting force, temperature, and vibration, providing valuable feedback to optimize the cutting process further.

Key Considerations:

Tool Condition Monitoring: Real-time data can help detect tool wear, allowing manufacturers to adjust cutting parameters or replace tips before tool failure occurs.

Systèmes de contrôle adaptatifs: Some systems can automatically adjust cutting parameters based on real-time conditions, ensuring optimal performance and reducing the need for manual intervention.

By incorporating real-time monitoring, manufacturers can fine-tune cutting parameters to maintain consistent precision and efficiency throughout the production process.

Conclusion

Optimizing cutting parameters with tungsten carbide tips is essential for improving production efficiency in manufacturing.

By adjusting parameters such as cutting speed, feed rate, depth of cut, and cooling methods, manufacturers can achieve a perfect balance between tool life, cutting precision, and operational efficiency.

Tungsten carbide tips offer exceptional durability and performance, making them the ideal choice for high-speed, high-precision cutting applications.

By optimizing these parameters, businesses can enhance productivity, reduce costs, and ensure that they remain competitive in the manufacturing industry.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.