Dans des industries comme exploitation minière, drilling, and machining, the durability of tools is essential for maintaining productivity and minimizing costs. Tungsten carbide tips are commonly used for their dureté, résistance à l'usure, and overall durability.

However, the process of bonding tungsten carbide to a metal substrate is a critical factor in determining the tool’s long-term performance.

Optimizing this bonding process ensures better durability, longer tool life, and consistent performance, even in the most demanding applications.

In this blog, we will explore the importance of the bonding process in tungsten carbide tips and how optimizing it can lead to more durable and efficient tools.

1. Understanding the Bonding Process in Tungsten Carbide Tips

Tungsten carbide tips are often bonded to a metal substrate, such as steel, to create a composite material that combines the strength and résistance à l'usure of tungsten carbide with the dureté and flexibility of the metal.

This bonding process is crucial for ensuring that the carbide tip remains securely attached to the substrate during use.

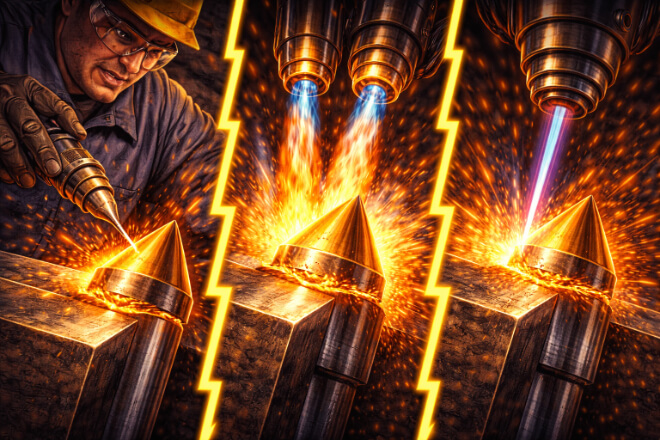

Key Bonding Methods:

Soldering: Involves using a filler material to bond the carbide tip to the substrate. It is suitable for low to moderate temperature applications.

Brazing: A more robust bonding method that uses a molten filler metal to create a strong joint. It is commonly used for high-temperature and high-stress applications.

Laser Welding: A precise method where a laser is used to melt the base material and form a solid bond with the carbide. This is often used for high-performance tools.

The choice of bonding method significantly affects the durability and performance of tungsten carbide tips, making it essential to optimize the bonding process.

2. Why Bonding Strength Is Crucial for Durability

The strength of the bond between the tungsten carbide tip and the metal substrate determines the tool’s ability to withstand wear, impact, and thermal stress.

A weak bond can cause the carbide tip to loosen or detach during use, leading to tool failure and reduced efficiency.

Optimizing the bonding process ensures that the carbide tip remains securely attached, even under extreme conditions.

Key Benefits of Strong Bonding:

Prevents Tip Detachment: A strong bond ensures the carbide tip stays securely attached to the metal substrate, preventing premature failure.

Améliore Résistance à l'usure: A well-bonded carbide tip resists wear more effectively, ensuring longer tool life and reducing the need for frequent replacements.

Enhanced Impact Resistance: Tools that undergo high-impact stresses benefit from stronger bonding, which helps absorb shock and prevent damage to the tip.

Optimizing the bonding process increases the overall durability of the tool, making it more reliable and cost-effective in the long term.

3. Optimizing the Soldering and Brazing Processes

Soldering and brazing are two common bonding methods used to attach tungsten carbide tips to metal substrates.

While both methods involve the use of a filler material to create the bond, they require careful temperature control and the right materials to achieve the best results.

Optimizing Soldering:

Proper Temperature Control: The temperature at which soldering occurs must be carefully controlled to avoid overheating the tungsten carbide tip, which could lead to loss of hardness and performance.

Choosing the Right Solder: The solder used in the bonding process should be compatible with both the tungsten carbide and the metal substrate to ensure a strong, durable bond.

Optimizing Brazing:

Choosing the Right Brazing Filler: The brazing filler material must be chosen based on the specific application to ensure it can withstand high temperatures and provide a strong bond.

Heat Treatment: After brazing, heat treatment is often required to relieve stress and enhance the bond strength, ensuring the carbide tip remains firmly attached under extreme conditions.

Optimizing these processes helps create a stronger, more durable bond, enhancing the tool’s overall performance in high-stress applications.

4. The Role of Laser Welding in Bonding Tungsten Carbide Tips

Laser welding is an advanced bonding method that uses a focused laser beam to melt the base material and form a bond with the carbide tip.

This method offers several advantages, including precision, speed, and the ability to create high-strength bonds.

Key Advantages of Laser Welding:

Précision: Laser welding allows for precise control of the heat and bonding area, reducing the risk of overheating and damaging the tungsten carbide tip.

Strong, Durable Bond: Laser welding creates a high-strength bond that can withstand high temperatures, impacts, and wear, making it ideal for heavy-duty applications.

Minimal Distortion: Since laser welding uses minimal heat, it reduces the chances of distortion in the metal substrate, ensuring that the bond remains stable and the tool retains its shape.

Optimizing laser welding techniques ensures the best possible bond strength and durability for tungsten carbide tips, especially in high-performance applications.

5. Impact of Bonding Materials on Durability

The materials used in the bonding process play a significant role in the final durability of tungsten carbide tips.

The choice of substrate, filler material, and bonding method must be carefully selected to meet the specific demands of the application.

Key Considerations for Bonding Materials:

Compatibilité: The filler material must be compatible with both the tungsten carbide and the metal substrate to create a strong bond that can withstand stress.

High-Temperature Resistance: The bonding material must be able to withstand the high temperatures generated during drilling or cutting operations without breaking down.

Résistance à l'usure: The bonding material should also have good wear resistance to ensure the bond remains intact throughout the tool’s life.

By optimizing the selection of bonding materials, manufacturers can improve the performance and longevity of their tungsten carbide-tipped tools.

6. Testing and Quality Control for Bonding Strength

To ensure that the bonding process has been optimized for durability, it is essential to conduct thorough testing and quality control.

Various testing methods can be used to assess the strength and reliability of the bond, including:

Shear Testing: Measures the bond’s ability to resist shearing forces.

Impact Testing: Tests the bond’s ability to withstand sudden shocks and impacts.

Thermal Cycling: Assesses the bond’s resistance to temperature fluctuations by subjecting the tool to cycles of heating and cooling.

Regular testing helps ensure that the bonding process meets the required standards and provides the durability necessary for demanding applications.

7. Optimizing Bonding for Specific Applications

Different applications require different levels of durability and performance.

By optimizing the bonding process for specific uses, manufacturers can ensure that their tools are suited for the job at hand.

Whether it’s for high-speed machining, mining, or drilling through tough materials, the bonding process must be tailored to meet the specific demands of the application.

Key Considerations for Specific Applications:

High-Impact Applications: In applications like exploitation minière, the bonding process must be optimized to withstand high-impact forces without weakening the bond.

Applications à haute température: For industries like pétrole et gaz drilling, the bonding process must be optimized for high-temperature resistance to prevent failure in extreme conditions.

By customizing the bonding process for each application, manufacturers can ensure that their tungsten carbide tips provide optimal performance and longevity.

Conclusion

Optimizing the bonding process of tungsten carbide tips is essential for improving tool durability and performance.

By carefully selecting the right bonding method, materials, and processes, manufacturers can create tools that withstand the toughest conditions and last longer.

Whether using soldering, brazing, or laser welding, optimizing the bonding process enhances the strength and reliability of tungsten carbide tips, making them the ideal choice for industries that rely on precision, durability, and performance.

With the right bonding process, companies can reduce maintenance costs, increase productivity, and ensure that their tools deliver consistent results over time.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.