Dans des industries telles que exploitation minière, pétrole et gaz, formage des métaux, papier, emballage et travail du bois, tungsten carbide wear parts are critical for reliable performance.

These parts face constant friction, heat, pressure, and impact. If quality is not consistent, the risk of downtime, high replacement cost, and machine damage increases.

This is why quality standards play a key role. For decision-makers, understanding how pièces d'usure en carbure de tungstène are tested, measured, and certified is important when choosing the right supplier.

This article explains the main quality factors, testing methods, and global standards that ensure long-lasting and reliable performance.

Que sont les pièces d’usure en carbure de tungstène ?

Tungsten carbide wear parts are components designed to resist wear, abrasion, and impact.

They are produced by combining poudre de carbure de tungstène with a binder metal (usually cobalt or nickel) through a process of pressing and sintering.

Voici quelques exemples :

Dies and punches for metal forming.

Cutting blades and knives for paper and woodworking.

Valve seats, seals, and nozzles for pétrole et gaz.

Drilling and mining tools for construction and quarrying.

Because these parts work under tough conditions, quality standards ensure that they perform consistently.

Why Quality Standards Matter

Consistency in performance – ensures that every part meets the same hardness, dureté, and dimensional accuracy.

Safety – poorly made pièces d'usure can fail, causing accidents or expensive machine breakdowns.

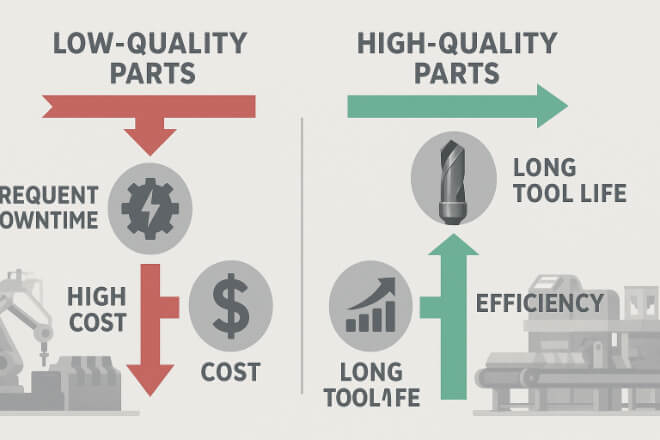

Cost efficiency – high-quality carbide parts last longer, reducing downtime and replacement needs.

Customer trust – industries rely on certified suppliers to deliver reliable components.

Key Quality Factors for Tungsten Carbide Wear Parts

1). Dureté

Hardness defines how well the part can resist wear and abrasion. Tungsten carbide hardness is measured on the Vickers (HV30) or Rockwell A (HRA) scale.

2). Dureté

Toughness measures the ability to resist cracking or breaking under impact. A balance between hardness and toughness is essential.

Low porosity ensures that the part is strong and durable. High density indicates better bonding and fewer weak spots.

4). Grain Size

Fine grain size improves strength and résistance à l'usure. Coarse grains may be used for impact-heavy applications.

5). Dimensional Accuracy

Precision in size and tolerance is critical for tools that must fit into machines with micron-level accuracy.

Global Quality Standards for Carbide Wear Parts

| Standard | Region/Organization | Focus Area |

|---|---|---|

| ISO 9001 | International | Quality management systems |

| ISO 45001 | International | Health and safety in manufacturing |

| ASTM B777 | United States | Material standards for tungsten-based alloys |

| DIN ISO 3327 | Germany | Testing hardness of cemented carbides |

| GB/T 3488 | China | Standards for cemented carbide materials |

These standards ensure global uniformity in the production and testing of carbide wear parts.

Testing Methods Used in Quality Control

Dureté Testing – Rockwell or Vickers methods confirm wear resistance.

Transverse Rupture Strength (TRS) – checks how much stress the part can take before breaking.

Magnetic Saturation Test – measures cobalt binder content to ensure balance between dureté et dureté.

Microstructure Examination – checks grain size, porosité, and uniformity under a microscope.

Dimensional Inspection – CNC machines and CMM tools verify precise tolerances.

How to Evaluate a Supplier’s Quality Standards

Check Certifications – Ensure the supplier holds ISO 9001 and relevant carbide material certifications.

Request Test Reports – Ask for hardness, density, and TRS test data.

Audit Production Process – A reliable supplier should allow audits of pressing, sintering, and grinding processes.

Compare Performance Records – Look at real-world case studies from exploitation minière, pétrole et gaz, or manufacturing industries.

Benefits of Choosing High-Quality Tungsten Carbide Parts

Lower Total Cost of Ownership – fewer replacements and less downtime.

Higher Efficiency – consistent output with fewer machine stops.

Improved Safety – reduces risk of sudden failures.

Better Reputation – delivering reliable products strengthens customer trust.

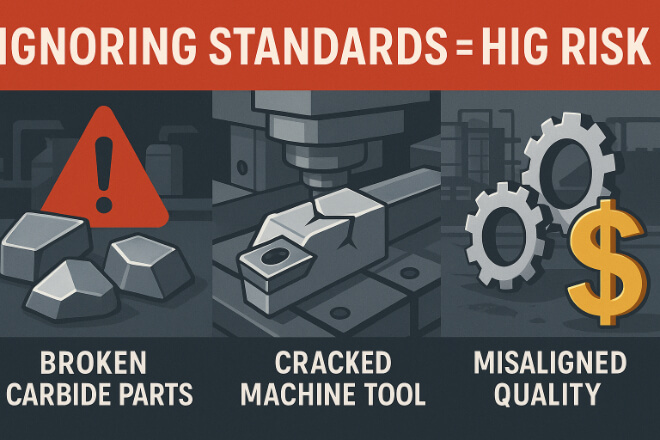

Common Issues When Standards Are Ignored

Parts cracking under high load.

Fast wear leading to downtime.

Dimensional mismatch with machines.

Inconsistent performance across batches.

These problems increase cost and can damage company reputation.

Conclusion

For decision-makers in heavy industries, quality standards for tungsten carbide wear parts are not optional—they are essential.

By choosing suppliers who follow global standards, companies ensure longer tool life, better efficiency, reduced downtime, and higher profitability.

The upfront investment in quality tungsten carbide wear parts pays off in the form of long-term savings and stable operations.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.