bagues en carbure de tungstène are known for their exceptional résistance à l'usure and long service life.

They protect rotating shafts, maintain alignment, and reduce friction in pumps, compressors, turbines, and other mechanical systems.

However, even the most durable bushing will eventually reach its wear limit.

Running equipment with a damaged or worn tungsten carbide bushing can lead to shaft misalignment, vibration, leakage, and catastrophic failure.

Knowing when to replace your bushings can prevent downtime, save maintenance costs, and extend the life of your entire system.

This article helps you identify the key warning signs and provides guidance on how to inspect, measure, and make smart replacement decisions.

Why Tungsten Carbide Bushings Wear Out

Tungsten carbide is extremely hard — but not invincible. Over time, it experiences mechanical wear, corrosion, and thermal fatigue.

The main causes of wear include:

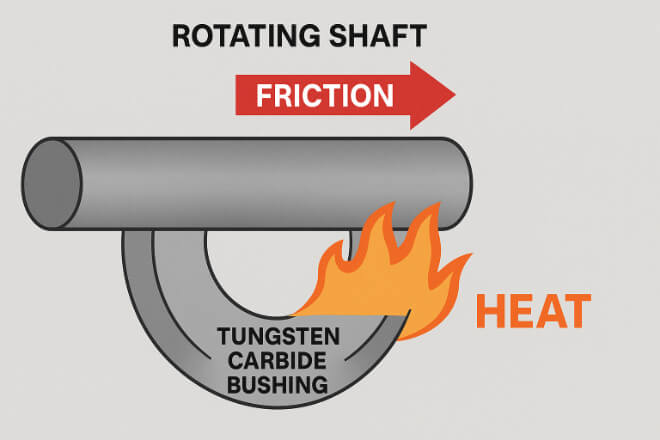

Continuous friction against the shaft surface

Poor lubrication or dry running

Particulate contamination in process fluids

Misalignment or vibration in the system

Thermal cycling and chemical corrosion

Understanding these wear mechanisms helps you interpret surface damage and decide the right time for replacement.

Visual Signs of Wear and Damage

Regular visual inspection is the simplest way to spot early damage. Below is a guide showing what to look for on the bushing surface.

| Type of Damage | Appearance | Possible Cause |

|---|---|---|

| Scoring or Scratches | Fine lines or grooves on surface | Insufficient lubrication or debris |

| Pitting | Small circular depressions | Corrosion or cavitation |

| Cracking | Visible hairline or branching cracks | Thermal shock or excessive load |

| Discoloration | Darkened or oxidized surface | Overheating or poor lubrication |

If you see deep grooves, cracks, or dull patches, it’s a clear indication that the bushing has reached its limit.

Performance-Related Warning Signs

Sometimes, the first signs of bushing failure come from performance changes, not visible wear.

Here are common symptoms to watch for during operation:

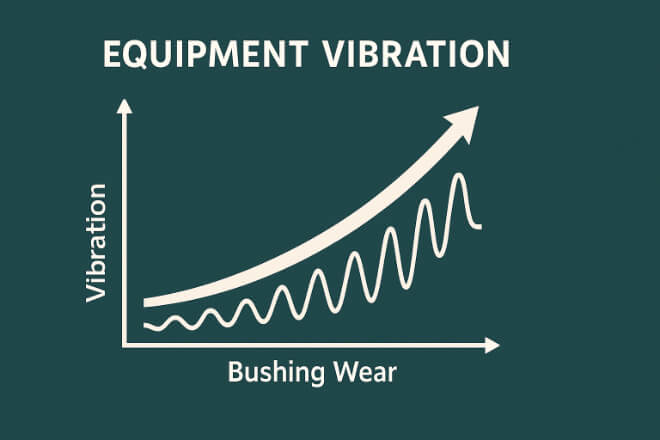

Increased vibration or noise: Caused by loss of concentricity between shaft and bushing.

Higher operating temperature: Indicates rising friction due to worn surfaces or poor lubrication.

Reduced efficiency: Pumps or compressors may lose pressure or flow.

Frequent shaft or seal failures: Suggests that the bushing no longer provides proper alignment.

Increased energy consumption: Friction or drag forces increase as the bushing wears.

Ignoring these symptoms can lead to expensive unplanned shutdowns.

Dimensional Inspection and Measurement

Visual checks are useful, but precise dimensional inspection confirms how much wear has occurred.

Measure the inner diameter (ID), outer diameter (OD), and roundness of the bushing regularly. Compare against original specifications.

Typical Wear Tolerance Guidelines:

| Paramètre | Allowable Wear Limit | Replacement Recommendation |

|---|---|---|

| Inner Diameter (ID) | > +0.05 mm from nominal | Replace to maintain shaft alignment |

| Outer Diameter (OD) | > −0.03 mm from housing tolerance | Replace to prevent looseness in housing |

| Roundness | > 0.01 mm deviation | Replace for uniform clearance and rotation |

For critical equipment, use air gauges, CMMs, or precision micrometers to achieve accurate readings.

Checking Surface Roughness and Flatness

As the bushing wears, the surface roughness (Ra) and flatness change, reducing the lubrication film stability. Measure Ra regularly using a surface profilometer.

Recommended values for working surfaces:

Ra 0.05–0.15 µm for high-speed rotating parts

Ra 0.2–0.3 µm for general industrial use

If the surface becomes too rough, friction increases — causing heat buildup and accelerated wear.

Flatness errors can lead to uneven pressure distribution, damaging the shaft and seals.

Chemical and Corrosion Damage

In chemical or marine environments, bagues en carbure de tungstène may face corrosion due to binder attack or pitting.

Key indicators of corrosion damage:

Small cavities or craters on surface

Loss of luster or dark film

Binder leaching, especially in Co-bonded grades

To reduce this problem, use Ni-bonded carbide or apply protective coatings like TiN or CrN for corrosive applications.

Noise and Vibration Analysis

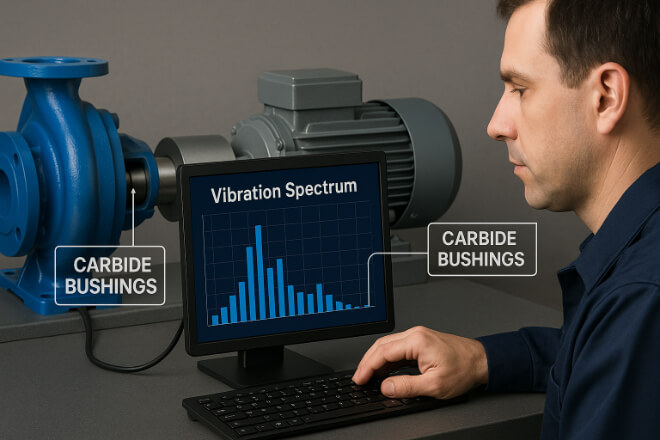

Condition monitoring tools can detect bushing degradation early.

Rising vibration amplitudes in specific frequency ranges suggest shaft–bushing clearance issues.

Sudden spikes in vibration often indicate cracks or partial failure.

Increasing noise during operation means loss of lubrication or misalignment.

Using vibration sensors and trend analysis helps you plan replacements before failure occurs.

Cost vs. Risk: When Replacement Is Justified

Replacing tungsten carbide bushings too early increases cost, but waiting too long risks shaft damage and system downtime.

A balanced approach uses both wear data and performance trends to decide replacement timing.

| Condition | Operational Risk | Action |

|---|---|---|

| Slight Wear, Stable Performance | Faible | Continue monitoring every 3 months |

| Moderate Wear, Minor Vibration | Moyen | Plan replacement during next maintenance cycle |

| Severe Wear or Surface Cracks | Haut | Immediate replacement required |

A scheduled replacement approach ensures zero unplanned shutdowns and protects expensive rotating components.

Preventive Maintenance Tips

To extend bushing life and delay replacement:

Maintain clean lubrication systems with proper oil viscosity.

Ensure correct shaft alignment during installation.

Use filters to remove debris from process fluids.

Regularly check temperature and vibration trends.

Avoid dry starts — always prime lubrication before operation.

Small preventive steps can add thousands of hours to bushing service life.

Conclusion

Even though tungsten carbide bushings are engineered for extreme durability, every component has a limit.

By combining visual inspection, dimensional measurement, vibration monitoring, and performance analysis, companies can accurately decide when to replace bushings before serious damage occurs.

Timely replacement minimizes downtime, maintains efficiency, and safeguards your equipment investment — ensuring long-term reliability in demanding industrial environments.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.