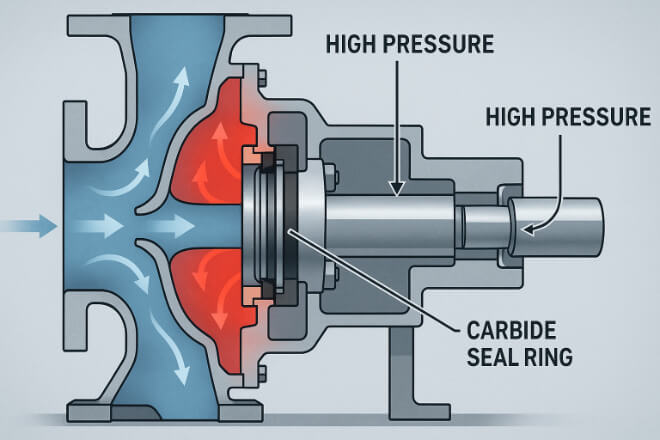

When mechanical seals operate under high differential pressure and high rotational speed (RPM), the demands on the sealing faces increase sharply.

These conditions cause greater surface stress, heat buildup, and fluid turbulence, which can quickly wear down an improperly sized or poorly selected seal ring.

Bagues d'étanchéité en carbure, particularly those made from tungsten carbide, are widely used for these severe applications.

They provide the dureté, strength, and thermal conductivity required to resist distortion and maintain a stable seal under dynamic pressure.

This article explains how to size carbide seal rings correctly for systems that operate under high pressure differences and high-speed rotation, while maintaining long-term performance and reliability.

The Challenge of High Differential Pressure

Differential pressure refers to the pressure difference between the inside and outside of a seal.

In high-pressure pumps or compressors, this difference can reach hundreds of bars.

If the seal ring is not properly designed, it may deform, crack, or even blow out of the housing.

To handle high differential pressure, a carbide seal ring must offer:

High compressive strength (above 5000 MPa)

Faible porosité to resist fluid penetration

Uniform stress distribution along the sealing face

Adequate thickness to prevent distortion

Even small dimensional errors can cause face distortion and leakage at high loads.

The following table summarizes common pressure categories and the corresponding recommended carbide ring thickness:

| Differential Pressure Range | Application typique | Recommended Ring Thickness | Material Suggestion |

|---|---|---|---|

| 0–10 bar | Water pumps, HVAC systems | 3–4 mm | Standard WC-Co |

| 10–40 bar | Pompes de procédés chimiques | 5–6 mm | Fine-grain WC-Co or WC-Ni |

| 40–100 bar | Oilfield and slurry service | 7–9 mm | High-strength WC-Ni |

| 100–200 bar | Compressors, downhole pumps | 10–12 mm | Coarse-grain WC-Co (impact-resistant) |

The thicker the ring, the more stable it becomes — but excessive thickness can increase weight and cost.

Therefore, balance is key between mechanical safety and rotational efficiency.

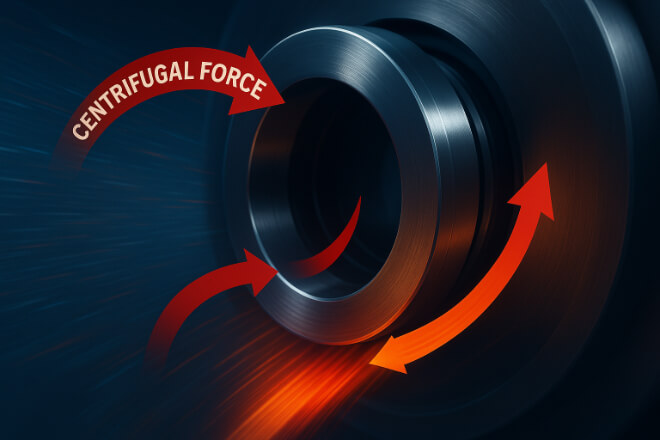

The Impact of High RPM on Seal Performance

High RPM generates centrifugal force, which affects how the seal faces contact and how heat is distributed.

At very high speeds, even small imbalances or misalignments can lead to vibration and rapid face wear.

The main effects of high RPM include:

Increased frictional heat

Reduced film thickness between faces

Thermal distortion of sealing surfaces

Potential for vibration-induced chipping

Tungsten carbide is ideal for these conditions because of its high modulus of elasticity and excellent heat transfer.

However, the geometry of the seal ring also plays a vital role.

A well-designed ring for high RPM service should have:

Lower face width to minimize drag

Optimized surface flatness (less than 2 light bands deviation)

Proper balance between inner and outer diameters to reduce centrifugal stress

For example, when RPM exceeds 6000, it’s critical to reduce the mass of the rotating ring without compromising its rigidity.

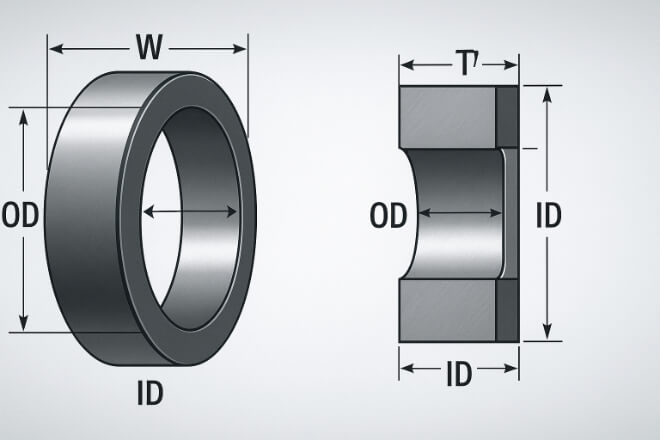

Balancing Pressure and Speed: The Key Design Factors

High differential pressure and high RPM rarely exist in isolation — they interact.

A ring that can handle 100 bar may fail at 10,000 RPM due to thermal expansion, and vice versa.

To size carbide seal rings effectively, engineers must consider four design parameters together:

Outer diameter (OD) – Controls contact area and mechanical stability.

Inner diameter (ID) – Affects rotational balance and fluid film formation.

Face width (W) – Influences pressure distribution and frictional load.

Thickness (T) – Determines resistance to deformation under pressure.

The following simplified ratio is often used as a starting guide:

Recommended Design Ratio:

OD : ID : W : T = 10 : 8 : 1 : 1

This ratio helps maintain structural balance while minimizing vibration and distortion.

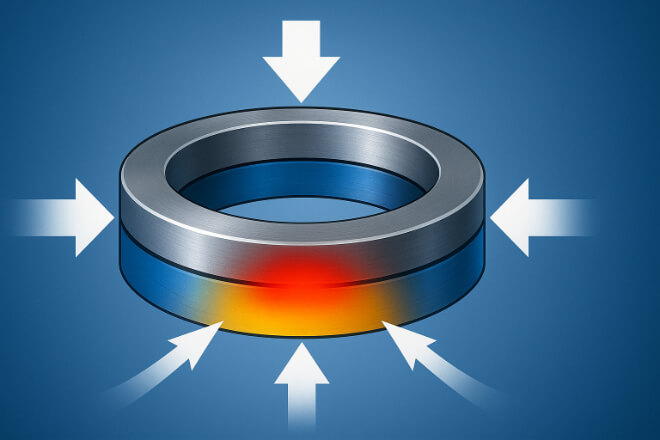

Managing Heat and Distortion in High-Load Conditions

At high speed and pressure, frictional heat becomes the silent enemy of seal performance.

Carbide materials can handle high temperatures, but only if heat is evenly dissipated.

Key ways to control heat and distortion include:

Using double mechanical seals for fluid circulation

Incorporating cooling channels or flush plans

Selecting fine-grain WC for higher thermal conductivity

Ensuring accurate lapping for face parallelism

If thermal gradients develop across the face, the ring can warp microscopically — causing leakage even when no visible damage is present.

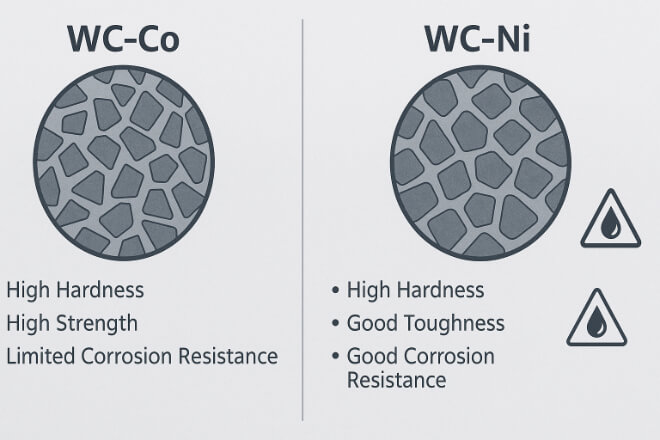

Material Selection: WC-Co vs. WC-Ni for Harsh Conditions

Not all carbide grades behave the same under combined stress.

Two common choices are Cobalt-bonded (WC-Co) and Nickel-bonded (WC-Ni) tungsten carbide.

Their mechanical and corrosion performance differ, as shown below:

| Carbide Type | Compressive Strength (MPa) | Résistance à la corrosion | Recommended Service |

|---|---|---|---|

| WC-Co | 5500–6000 | Modéré | High RPM, moderate chemical exposure |

| WC-Ni | 5000–5500 | Excellent | High pressure, aggressive chemicals |

WC-Co is more common for high RPM due to its strength and thermal conductivity, while WC-Ni is preferred for chemically aggressive, high-pressure environments.

In some applications, a hybrid pair (WC-Co vs. WC-Ni) can provide an optimal balance.

Practical Tips for Sizing Carbide Seal Rings

For companies dealing with rotating machinery and high-load sealing systems, correct sizing is not just a technical issue — it’s a matter of operational reliability and cost control.

Here are practical guidelines to follow:

Determine both static and dynamic pressure before finalizing dimensions.

Confirm maximum RPM of the equipment, not just normal operating speed.

Check the fluid viscosity and lubrication quality — thin fluids increase friction.

Always use a safety factor of at least 1.2 for pressure rating.

Consult material suppliers for specific density and modulus data before final machining.

Avoid sharp corners or edges on the ring that can concentrate stress.

Perform dynamic balancing tests for assemblies exceeding 8000 RPM.

These steps help ensure that the seal maintains its flatness, tightness, and life span even under the most demanding conditions.

Conclusion

Correctly sizing carbide seal rings for high differential pressure and high RPM is essential to ensure reliable sealing performance and long equipment life.

It requires understanding the interplay between pressure, speed, geometry, and material selection.

With the right design and quality tungsten carbide grades, your sealing system can operate smoothly even in the harshest industrial environments — minimizing downtime and maintenance costs.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.