Dans les outils industriels hautes performances, notamment ceux en carbure de tungstène, l'état de surface n'est pas seulement un attribut esthétique : c'est un facteur technique clé qui influence directement les performances, la longévité et la compatibilité des outils avec les applications. Cet article explore la signification de l'état de surface, son importance pour les outils en carbure cémenté, son mode de mesure et son optimisation en production.

Qu'est-ce que la finition de surface ?

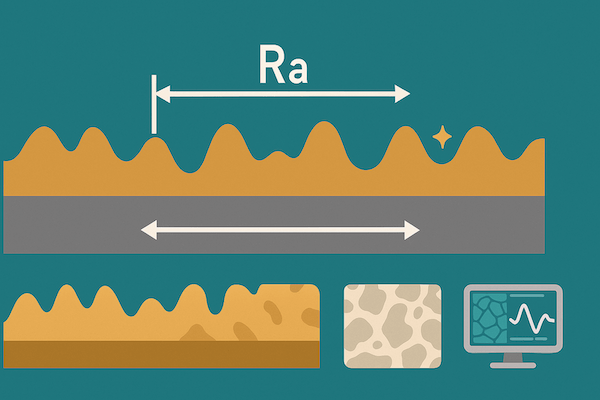

La finition de surface fait référence à la texture et à la qualité de la surface d'un outil après usinage, meulage ou polissage. Il comprend les pics et les vallées microscopiques présents à la surface du matériau et est généralement quantifié par des paramètres tels que :

Ra (rugosité moyenne)

Rz (hauteur maximale du profil)

Rt (hauteur totale du profil)

Une finition de surface plus lisse signifie généralement moins d'imperfections et une meilleure résistance à l'usure, et une friction réduite en service.

Importance de la finition de surface des outils en carbure de tungstène

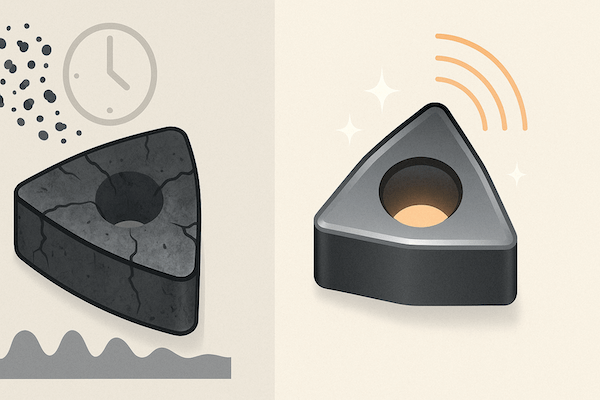

1. Résistance à l'usure et durée de vie de l'outil

Le carbure de tungstène est un matériau dur et résistant à l'usure utilisé dans coupe, perçage et formage. Une finition de surface lisse :

Réduit l'abrasion des matériaux de travail

Minimise les concentrations de contraintes au niveau des défauts de surface

Empêche le délaminage prématuré du revêtement

Le résultat est un outil plus durable, en particulier dans les environnements à grande vitesse ou à utilisation continue.

2. Frottement et génération de chaleur

Les surfaces rugueuses augmentent la friction et la chaleur localisée, ce qui peut dégrader l'outil et la pièce. Les finitions de surface soignées réduisent :

Résistance à la coupure

Formation d'arêtes rapportées dans les outils de coupe

Accumulation de chaleur à l'interface outil-pièce

Ceci est essentiel pour l'usinage de matériaux délicats ou pour fonctionner dans des conditions de coupe à sec.

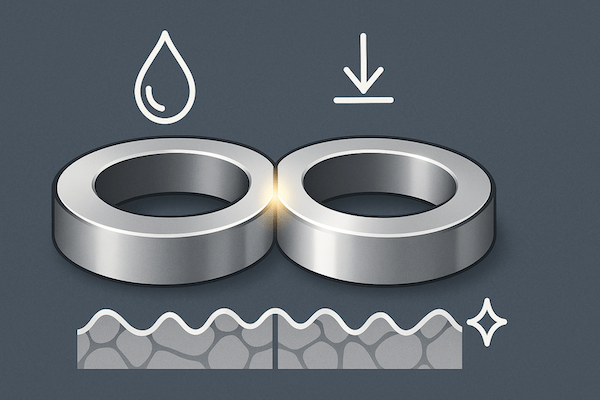

3. Performances de la surface d'étanchéité et de contact

Dans sièges de soupapes, bagues d'étanchéité, et meurtLa finition de surface détermine l'étanchéité et l'ajustement mécanique. Des finitions ultra-fines sont nécessaires pour :

Prévenir les fuites de gaz ou de liquide

Assurer une pression et un contact constants sur toutes les surfaces

Minimiser les vibrations et le bruit pendant le fonctionnement

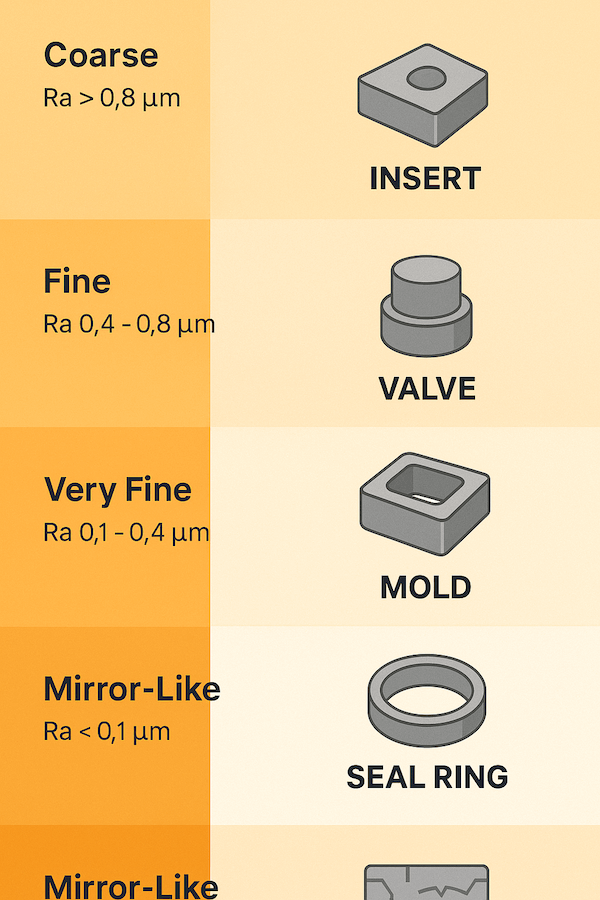

Qualités et applications de finition de surface

| Finition de surface (Ra µm) | Exemple d'application |

|---|---|

| 0,01 – 0,05 | Bagues d'étanchéité, outils médicaux (poli miroir) |

| 0,05 – 0,2 | Sièges de soupapes, moules de précision |

| 0,2 – 0,8 | Plaquettes de coupe, pointes de perçage |

| 0,8 – 1,6 | Ébauches brutes, outils semi-finis |

Comment la finition de surface est mesurée

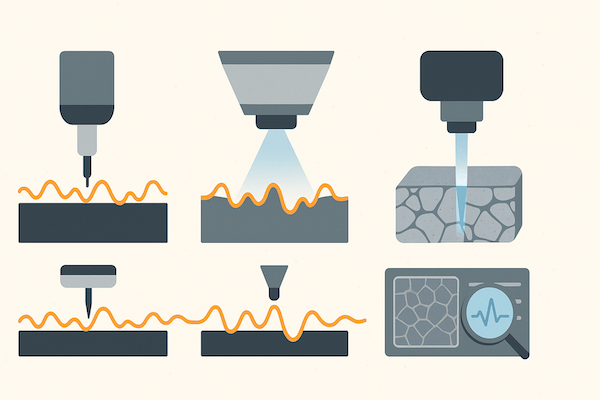

Les méthodes courantes de métrologie de surface comprennent :

Profilomètres de contact : utilisez un stylet pour tracer la surface et enregistrer les variations verticales.

Interféromètres optiques : utilisent des motifs d'interférence lumineuse pour évaluer la finition à l'échelle nanométrique.

Microscopie à lumière blanche / Numérisation laser 3D : Offre une cartographie de surface haute résolution sans contact.

Dans la production de carbure, ces outils aident les fabricants à respecter des spécifications de finition précises pour chaque application.

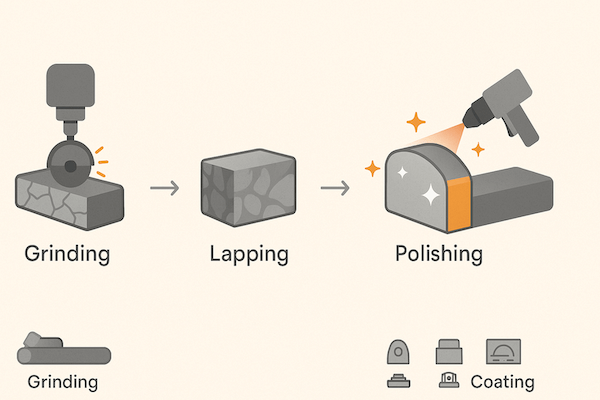

Comment la finition de surface est obtenue dans la production d'outils en carbure

Outils en carbure de tungstène passer par plusieurs étapes de finition pour obtenir la qualité de surface souhaitée :

Rectification de précision – Façonne l’outil et supprime les marques d’usinage.

Rodage – Produit des surfaces de contact planes et lisses à l’aide d’une boue abrasive.

Polissage – Fournit des surfaces semblables à un miroir pour des applications de haute spécification.

Revêtement (facultatif) – Ajoute des couches résistantes à l’usure sans compromettre la finition de base.

Chaque étape doit être strictement contrôlée, en particulier pour les outils utilisés dans scellage, électronique, ou médicalenvironnements de qualité.

Conclusion

Dans le monde des outils en carbure de tungstène, l'état de surface est un facteur déterminant de performance, de fiabilité et de compatibilité des applications. Que vous produisiez des joints d'étanchéité, des inserts de moule ou outils de coupe, obtenir une finition de surface parfaite peut faire la différence entre un échec et un fonctionnement impeccable. Face à des normes de fabrication de plus en plus exigeantes, la finition de surface de précision demeure un facteur concurrentiel clé dans le secteur. industrie de l'outillage en carbure.