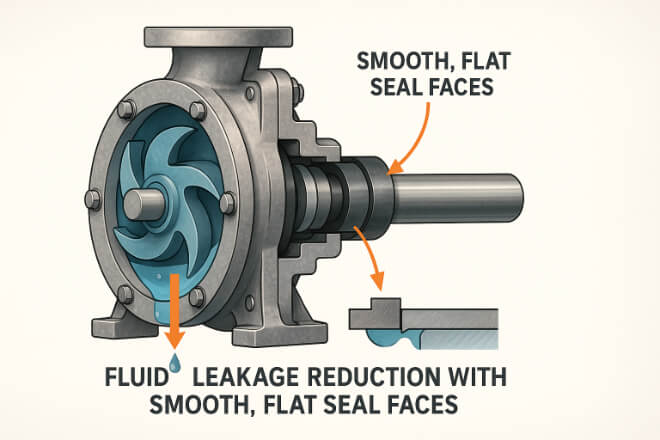

Carbide seal faces are critical for pumps, compressors, and vannes in industries like pétrole et gaz, power generation, chemical processing, and water treatment.

The surface roughness (Ra) and flatness of these seal faces directly affect leakage control, résistance à l'usure, and equipment reliability.

Lapping and polishing are two essential finishing processes that define the final Ra and flatness.

Decision-makers must understand the best practices for achieving target values to ensure longer service life, reduced maintenance, and cost savings.

Why Ra and Flatness Matter

Leakage control: Smooth and flat surfaces create tighter seals.

Wear resistance: Proper surface finish reduces friction and prevents premature wear.

Energy efficiency: Reduced friction lowers power consumption.

Operational reliability: Well-lapped faces minimize risk of catastrophic seal failure.

Understanding Surface Roughness (Ra)

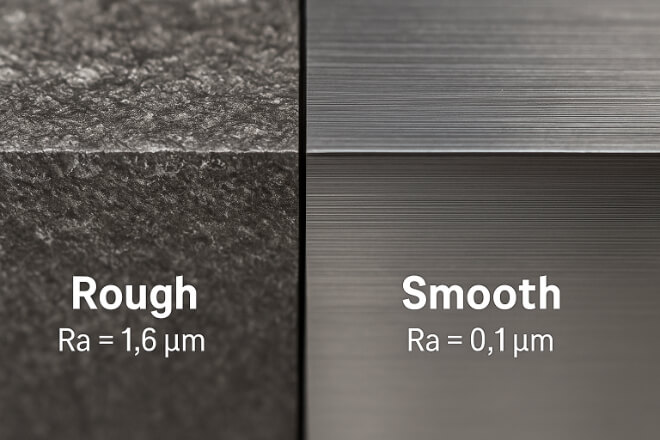

Ra is the average height of surface irregularities. Lower Ra means a smoother surface.

High Ra values: Surfaces are rougher, which can cause turbulence and leakage.

Low Ra values: Provide tighter seals and lower friction but require more precise finishing.

Typical Target Ra for Carbide Seal Faces

General service pumps: Ra 0.2–0.4 μm.

High-pressure or critical service: Ra 0.1–0.2 μm.

Ultra-clean applications (e.g., pharma or semiconductor): Ra ≤0.1 μm.

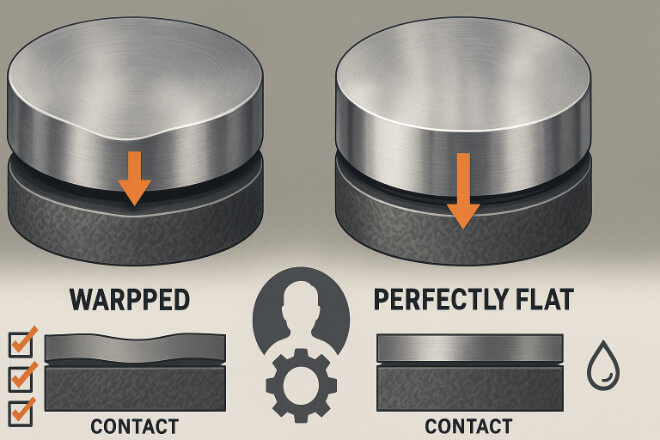

Understanding Flatness

Flatness is the deviation of a surface from a perfect plane. In seals, flatness determines how well two faces mate under pressure.

Poor flatness: Leads to gaps and leakage paths.

Tight flatness: Ensures uniform contact and prevents hot spots or uneven wear.

Typical Flatness Targets

Standard seals: ≤2–3 light bands (0.000025–0.000038 mm).

Critical applications: ≤1–1.5 light bands.

Lapping Best Practices

Lapping uses an abrasive slurry on a flat plate to remove small amounts of material and improve flatness.

1). Steps for Effective Lapping

Select the right abrasive: Diamond slurry for tungsten carbide.

Use stable fixtures: Maintain even pressure to avoid tapering.

Monitor flatness: Check frequently using optical flats and monochromatic light.

Use incremental passes: Remove material gradually to prevent over-lapping.

2). Common Mistakes to Avoid

Applying excessive pressure, which can warp the surface.

Using contaminated slurry, which can scratch the face.

Skipping intermediate checks, leading to uneven surfaces.

Polishing Best Practices

Polishing removes fine scratches from lapped surfaces and achieves the final Ra.

1). Steps for Effective Polishing

Choose the proper pad and slurry: Use soft polishing pads with fine diamond paste.

Maintain cleanliness: Even small particles can ruin the surface finish.

Control heat and pressure: Excessive heat can cause distortion or microcracks.

Inspect with profilometers: Verify that Ra values meet specifications.

Comparison Table: Lapping vs Polishing

| Aspect | Lapping | Polissage |

|---|---|---|

| But | Improves flatness | Refines surface finish (Ra) |

| Abrasive Type | Diamond slurry on flat plate | Fine diamond paste on soft pad |

| Material Removal | Modéré | Minimal |

| Finish Quality | Prepares for polishing | Achieves final Ra and appearance |

Common Problems and How to Avoid Them

Warped surfaces: Use even pressure and proper fixtures.

Scratches or pits: Keep workstations clean and use uncontaminated abrasives.

Uneven finish: Alternate rotation directions to distribute wear evenly.

Failure to meet Ra targets: Perform intermediate inspections and re-polish if necessary.

Industry Applications That Rely on Proper Ra and Flatness

Power plant boiler feed pumps where tight sealing prevents energy loss.

Chemical processing pumps handling aggressive fluids under high pressure.

Marine systems that need reliable sealing to prevent environmental contamination.

Pharmaceutical mixers where ultra-smooth finishes prevent bacterial growth.

Maintenance Tips for Long-Term Performance

Inspect carbide faces at scheduled intervals for scratches or wear.

Re-lap and polish worn faces instead of replacing entire seals when possible.

Store carbide components in clean, dry environments to prevent contamination.

Work with suppliers who provide detailed Ra and flatness data for quality assurance.

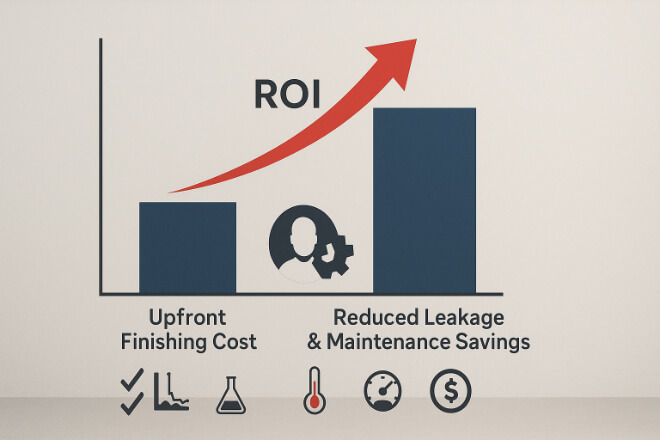

Considérations relatives aux coûts et au retour sur investissement

Upfront investment: Precision lapping and polishing may cost more initially.

Savings: Reduced leakage, fewer breakdowns, and extended seal life lower total costs.

ROI: Consistent sealing performance improves operational reliability and reduces downtime.

Conclusion

Target Ra and flatness are critical for carbide seal face stability and leakage control. Following lapping and polishing best practices ensures tight seals, longer component life, and cost-effective operation.

Decision-makers who prioritize surface finish quality will achieve better equipment reliability and avoid unnecessary downtime.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.